Automatic bottle packing device for hand sanitizer gel production line

A technology for sterilizing gel and bottle packaging, applied in packaging, packaging bottles, packaging machines, etc., can solve the problems of unreliable monitoring, inadequate monitoring, poor reliability, etc., and achieve reasonable overall layout design, ingenious technical ideas, and reliable work. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

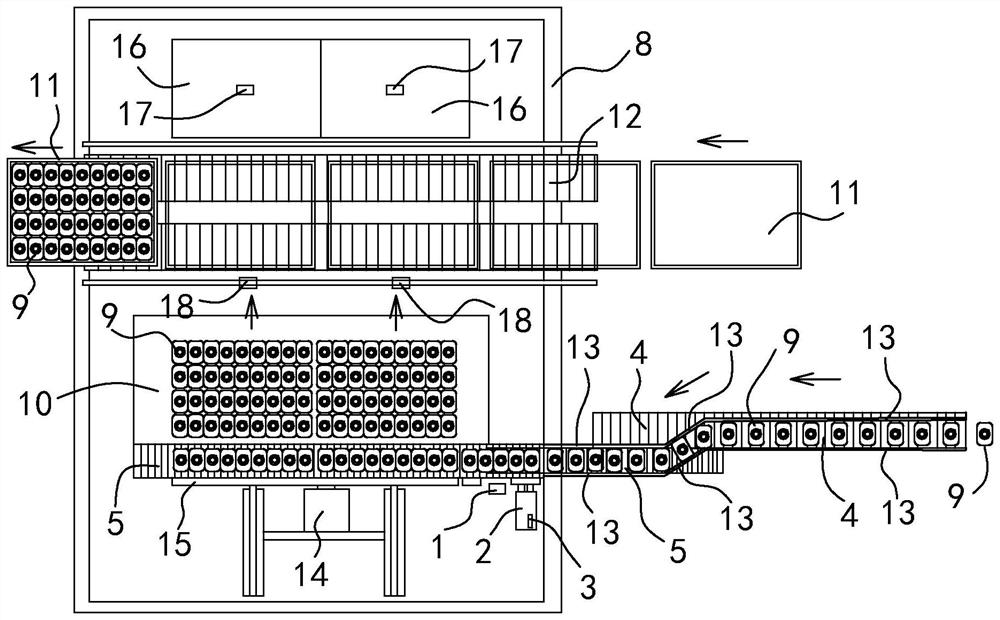

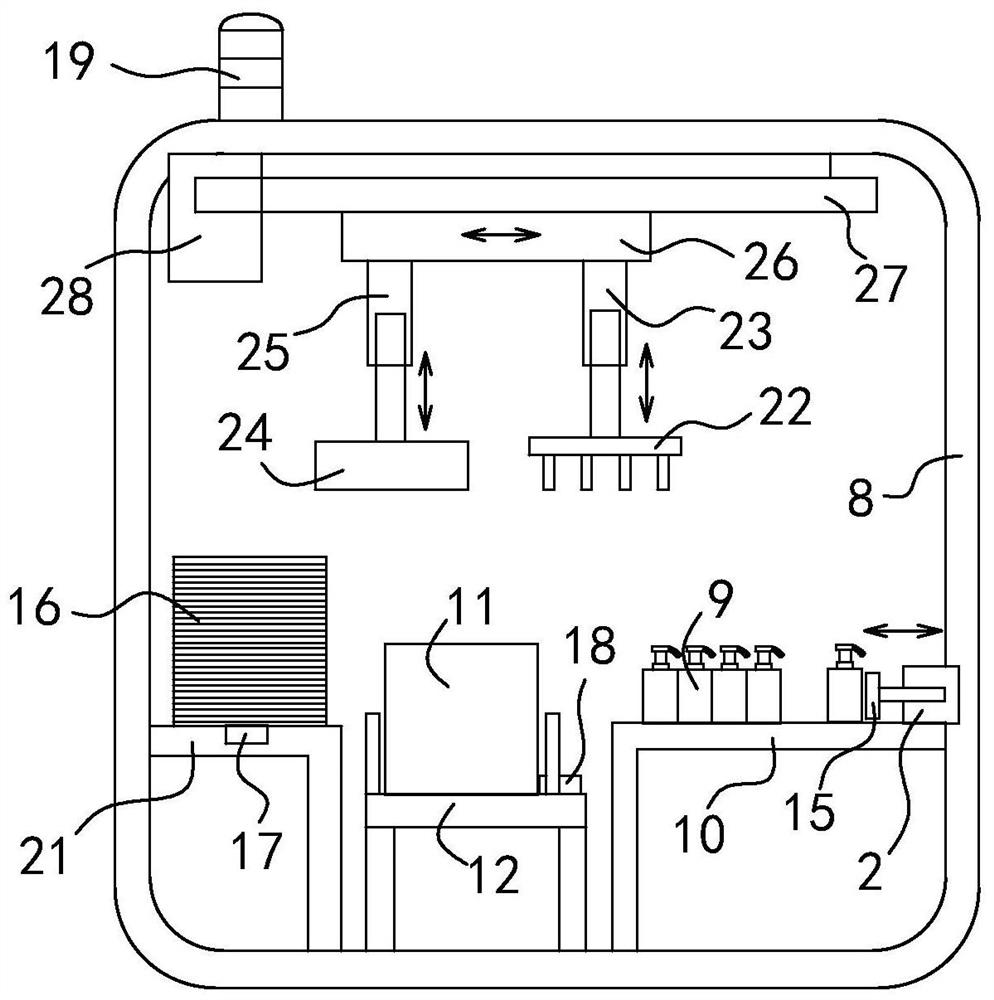

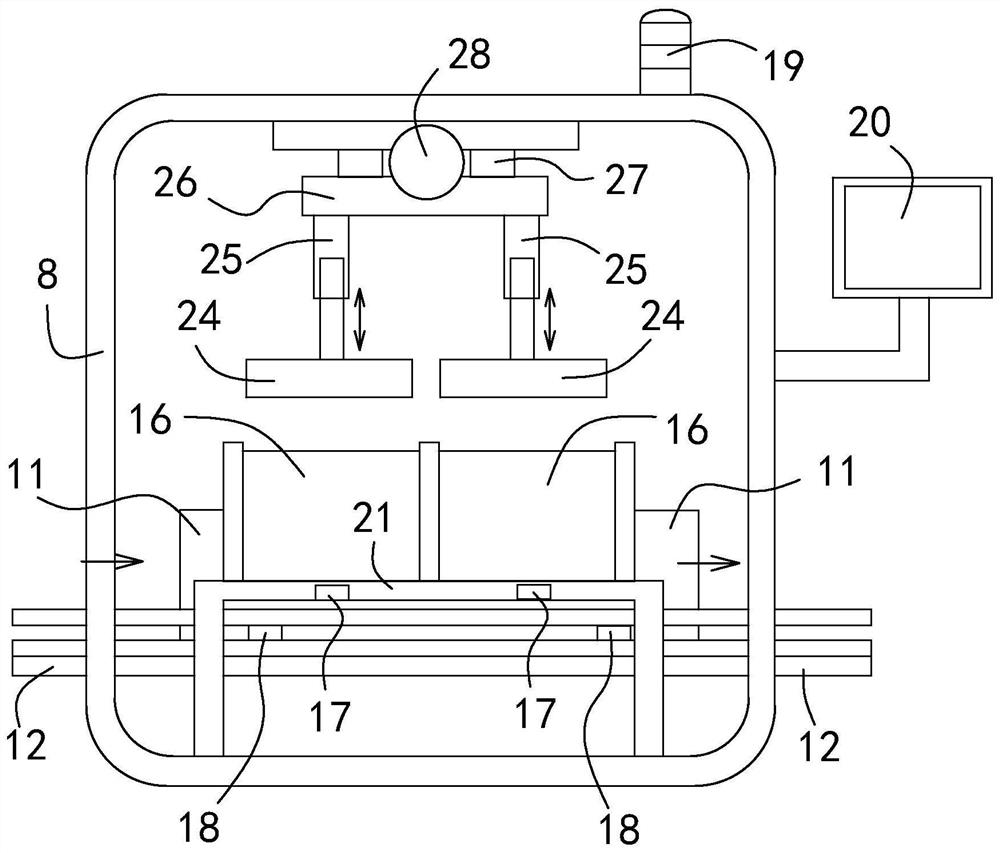

[0027] Example: an automatic bottle packing device for a hands-free disinfection gel production line

[0028] Such as Figure 1-6 As shown, for the boxed gel bottle 9, the carton 11 and the cardboard 16 at the bottom and top of the carton 11, the automatic bottle packing device includes a frame 8, a bottle conveying mechanism, a box conveying mechanism, and a cardboard placement platform 21 and the bottle plate transfer mechanism (see Figure 1-4 ).

[0029] The bottle conveying mechanism is mainly composed of a bottle conveying belt, a bottle pushing platform 10, a bottle pushing cylinder 14, a bottle pushing plate 15, a bottle retaining cylinder 2 and a counting sensor 1 (see figure 1 and Figure 4 ). The bottle conveying belt is a conveyor belt mechanism driven by a motor for conveying the gel bottle 9, and the conveyor belt mechanism is positioned relative to the frame 8 and arranged on the bottle conveying path of the gel bottle 9 (see figure 1 ). The bottle pushing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com