Preparation method of a cellulose-based underwater adhesive hydrogel

A cellulose and hydrogel technology, which is used in the preparation of underwater adhesive hydrogels, can solve the problems of weak underwater adhesion and low self-healing efficiency of gels, and achieve good underwater adhesion. effect, excellent adhesion, excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

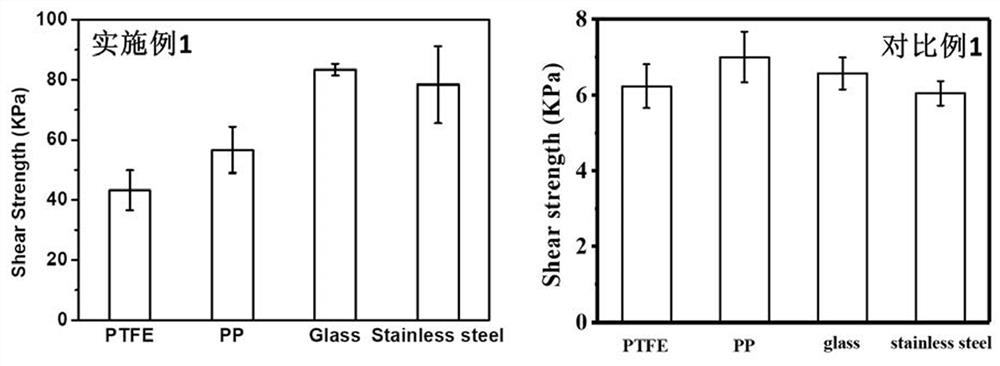

Embodiment 1

[0027] A preparation method of cellulose-based underwater adhesive hydrogel, comprising the following steps:

[0028] (1) Preparation of cellulose-heteropolyacid complex solution: under stirring, 120 mg of methyl hydroxypropyl cellulose and 20 mg of ferric chloride hexahydrate were dissolved in 3.5 mL of distilled water to form a cellulose mixture; Dissolve 80 mg of tungstosilicic acid in 0.5 mL of distilled water to obtain an aqueous solution of tungstosilicate; slowly drop the aqueous solution of tungstosilicate into the cellulose mixed solution, stir and mix evenly to obtain a cellulose-tungstosilicate precursor;

[0029] (2) Preparation of hydrogel: Take 4 mL of cellulose-tungstosilicate precursor obtained in step (1), add 2.4 g of dimethylaminoethyl methacrylate monomer into it, stir and mix evenly, and then add the monomer Potassium persulfate with a molar mass of 1% was stirred evenly, and reacted at room temperature for 8 hours to obtain a brown-red hydrogel.

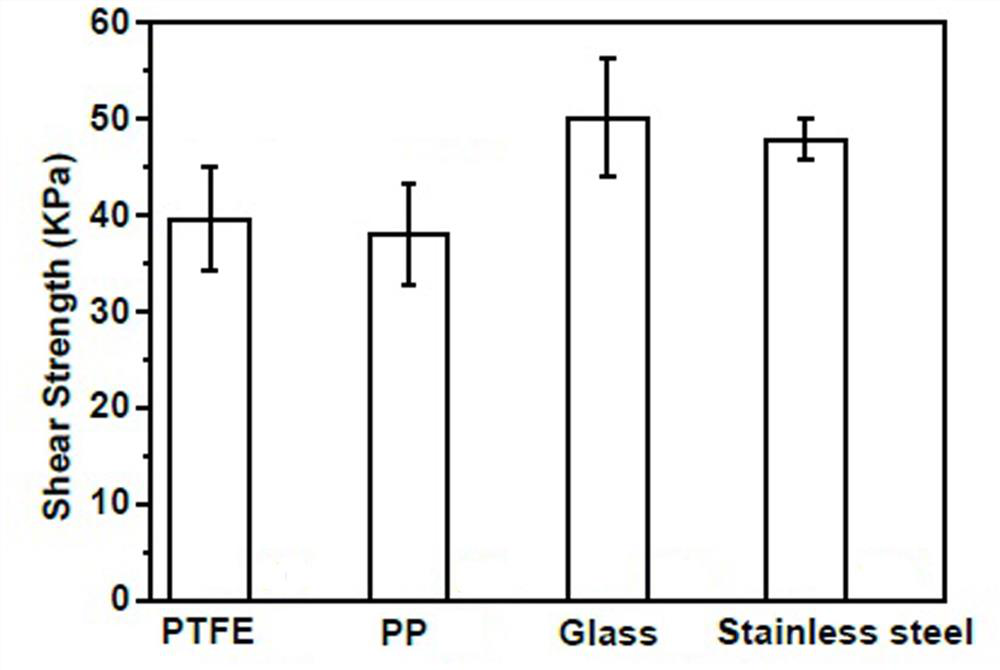

Embodiment 2

[0031] A preparation method of cellulose-based underwater adhesive hydrogel, comprising the following steps:

[0032] (1) Preparation of cellulose-heteropolyacid complex solution: under stirring, 120 mg hydroxyethyl cellulose and 20 mg ferric chloride hexahydrate were dissolved in 3.5 mL distilled water to form a cellulose mixture; 80 mg Dissolve tungstosilicic acid in 0.5 mL distilled water to obtain an aqueous tungstosilicic acid solution; slowly drop the aqueous tungstosilicic acid solution into the cellulose mixed solution, stir and mix evenly to obtain a cellulose-tungstosilicate precursor;

[0033] (2) Preparation of hydrogel: Take 4 mL of cellulose-tungstosilicate precursor obtained in step (1), add 2.4 g of dimethylaminoethyl methacrylate monomer into it, stir and mix evenly, and then add the monomer Potassium persulfate with a molar mass of 1% was stirred evenly, and reacted at room temperature for 8 hours to obtain a brown-red hydrogel.

Embodiment 3

[0035] A preparation method of cellulose-based underwater adhesive hydrogel, comprising the following steps:

[0036] (1) Preparation of cellulose-heteropoly acid complex solution: under stirring, 120 mg of methyl hydroxypropyl cellulose and 20 mg of aluminum chloride hexahydrate were dissolved in 3.5 mL of distilled water to form a cellulose mixture; Dissolve 80 mg of tungstosilicic acid in 0.5 mL of distilled water to obtain an aqueous solution of tungstosilicate; slowly drop the aqueous solution of tungstosilicate into the cellulose mixed solution, stir and mix evenly to obtain a cellulose-tungstosilicate precursor;

[0037] (2) Preparation of hydrogel: Take 4 mL of cellulose-tungstosilicate precursor obtained in step (1), add 2.4 g of dimethylaminoethyl methacrylate monomer into it, stir and mix evenly, and then add the monomer Potassium persulfate with a molar mass of 1% was stirred evenly, and reacted at room temperature for 8 hours to obtain a brown-red hydrogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

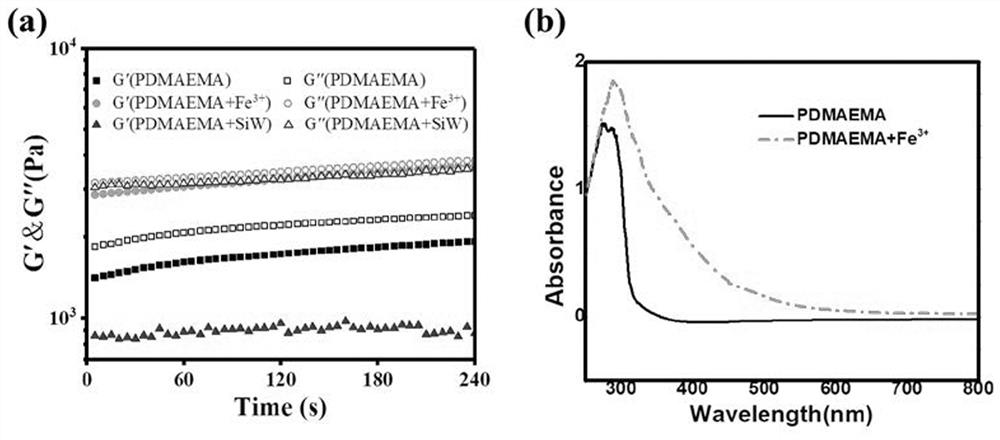

| modulus | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com