Transparent antifouling patch as well as preparation method and application thereof

An anti-fouling and patch technology, applied in the direction of film/sheet adhesive, adhesive type, amide/imide polymer adhesive, etc., can solve the problem of poor light transmission of hydrogel question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

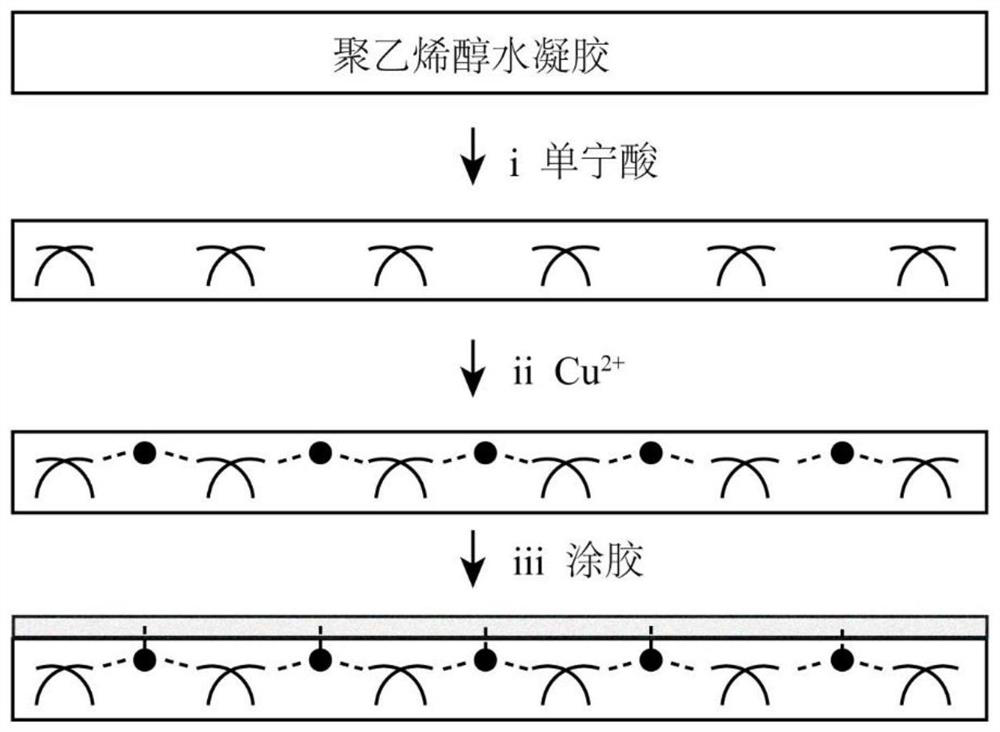

[0030] The invention provides a method for preparing a transparent antifouling patch, comprising the following steps;

[0031] Mix polyvinyl alcohol, water and glycerin and freeze to obtain a hydrogel;

[0032] Mixing the hydrogel with a tannic acid solution for pretreatment to obtain a pretreated hydrogel;

[0033] The pretreated hydrogel was treated with soluble Cu 2+ Salt solution treatment to obtain a hydrogel substrate;

[0034] mixing dopamine methacrylamide and hydrophobic monomers for free radical polymerization to obtain adhesives containing phenolic hydroxyl groups, the hydrophobic monomers being methoxyethyl acrylate or methyl methacrylate;

[0035] Mixing the adhesive glue containing phenolic hydroxyl groups with an organic solvent to obtain an adhesive glue solution;

[0036] Coating the adhesive glue solution on one side of the hydrogel base to obtain the transparent antifouling patch.

[0037] The invention mixes polyvinyl alcohol, water and glycerin and fre...

Embodiment 1

[0067] Weigh 10 parts of polyvinyl alcohol (the average degree of polymerization is 1750), 40 parts of glycerin, and 50 parts of deionized water are placed in a flask, and heated to reflux to dissolve the PVA. Then pour the obtained solution between the glass templates, the gap height is 0.36mm, put it into the environment of -30°C and freeze it, take it out after standing for 12 hours, and then freeze it after thawing at room temperature (-30°C, 12 hours) , to obtain polyvinyl alcohol hydrogel.

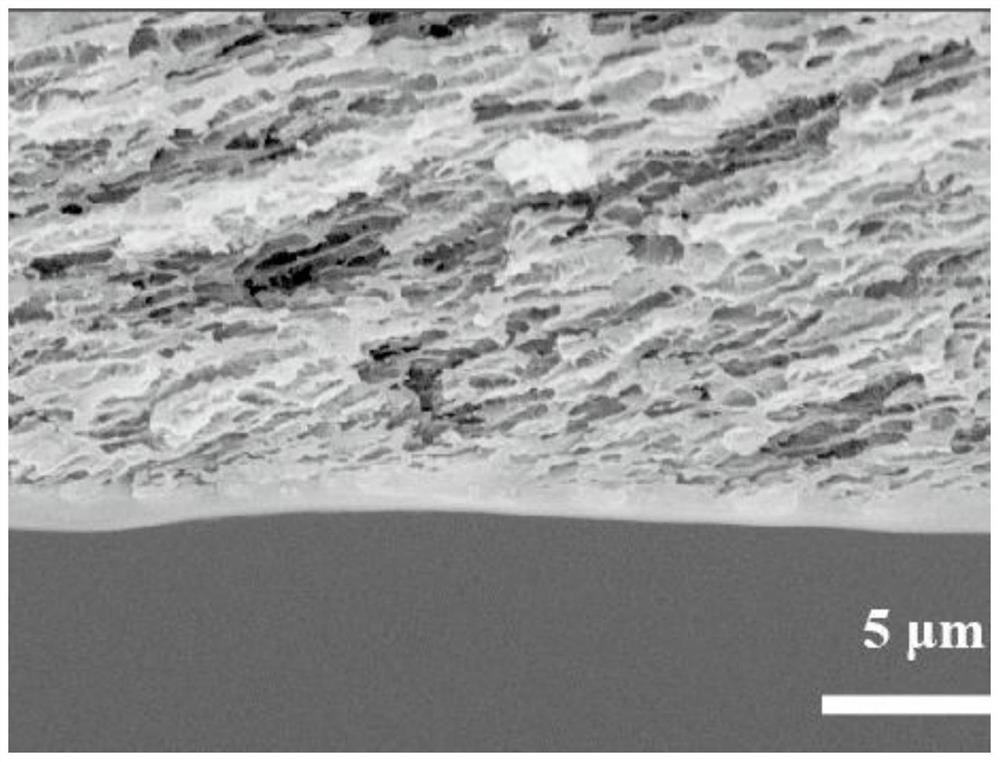

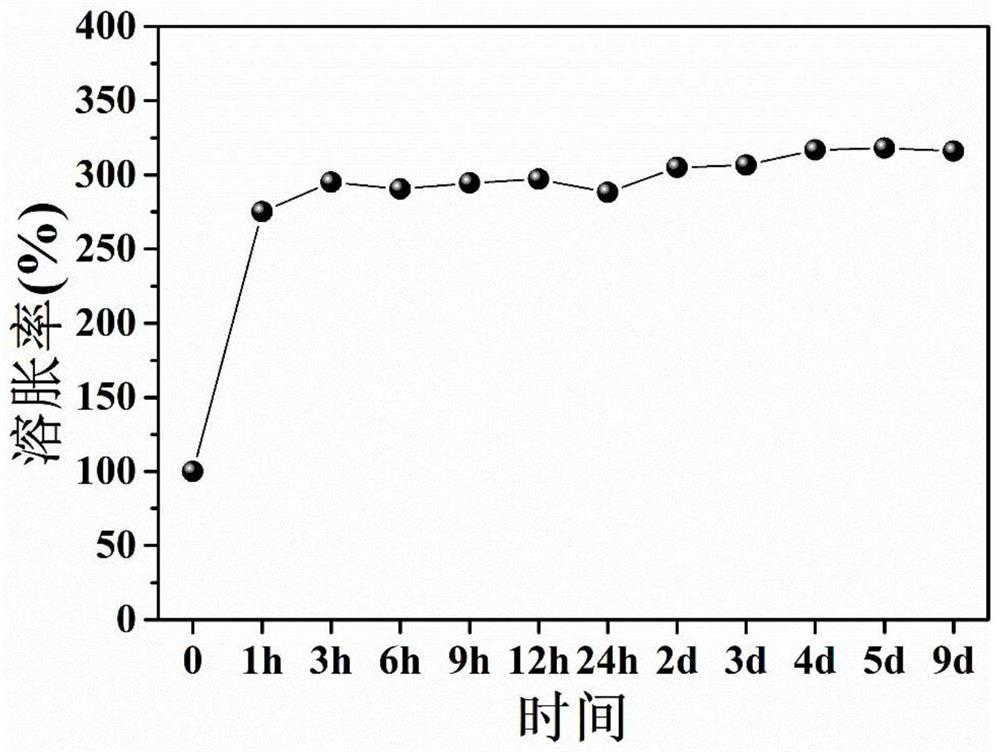

[0068] A 1% tannic acid solution was prepared, and the obtained hydrogel was soaked in the tannic acid solution for 1 hour. Configure 0.1mol / L CuCl 2 solution, the hydrogel treated with tannic acid was put into CuCl 2 solution, soak for 5min. 7.5g of methoxyethyl acrylate, 1.7g of dopamine methacrylamide and 106mg of azobisisobutyronitrile were added to 20mL of dimethylformamide for radical polymerization at 70°C to obtain an adhesive glue. The adhesive glue was dissolved in dich...

Embodiment 2

[0070] Weigh 10 parts of polyvinyl alcohol (average degree of polymerization: 1750), 50 parts of glycerin, and 40 parts of deionized water into a flask, set up a reflux condensation device, and heat to 135°C to dissolve PVA. Then pour the obtained solution between the glass templates, the gap height is 0.36mm, put it into the environment of -30°C and freeze it, take it out after standing for 12 hours, and then freeze it after thawing at room temperature (-30°C, 12 hours) , to obtain polyvinyl alcohol hydrogel.

[0071] A 1% tannic acid solution was prepared, and the obtained hydrogel was soaked in the tannic acid solution for 1 hour. Configure 0.1mol / L CuCl 2 solution, the hydrogel treated with tannic acid was put into CuCl 2 Solution, soak for 1h. 7.5g of methoxyethyl acrylate, 1.7g of dopamine methacrylamide and 106mg of azobisisobutyronitrile were added to 20mL of dimethylformamide for radical polymerization at 70°C to obtain an adhesive glue. The adhesive glue is disso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com