Polyaniline anti-corrosion coating for underwater or wet surfaces and preparation method thereof

An anti-corrosion coating, polyaniline technology, applied in the field of coatings, can solve the problems of the underwater anti-corrosion coating being difficult to lasting, toxic and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

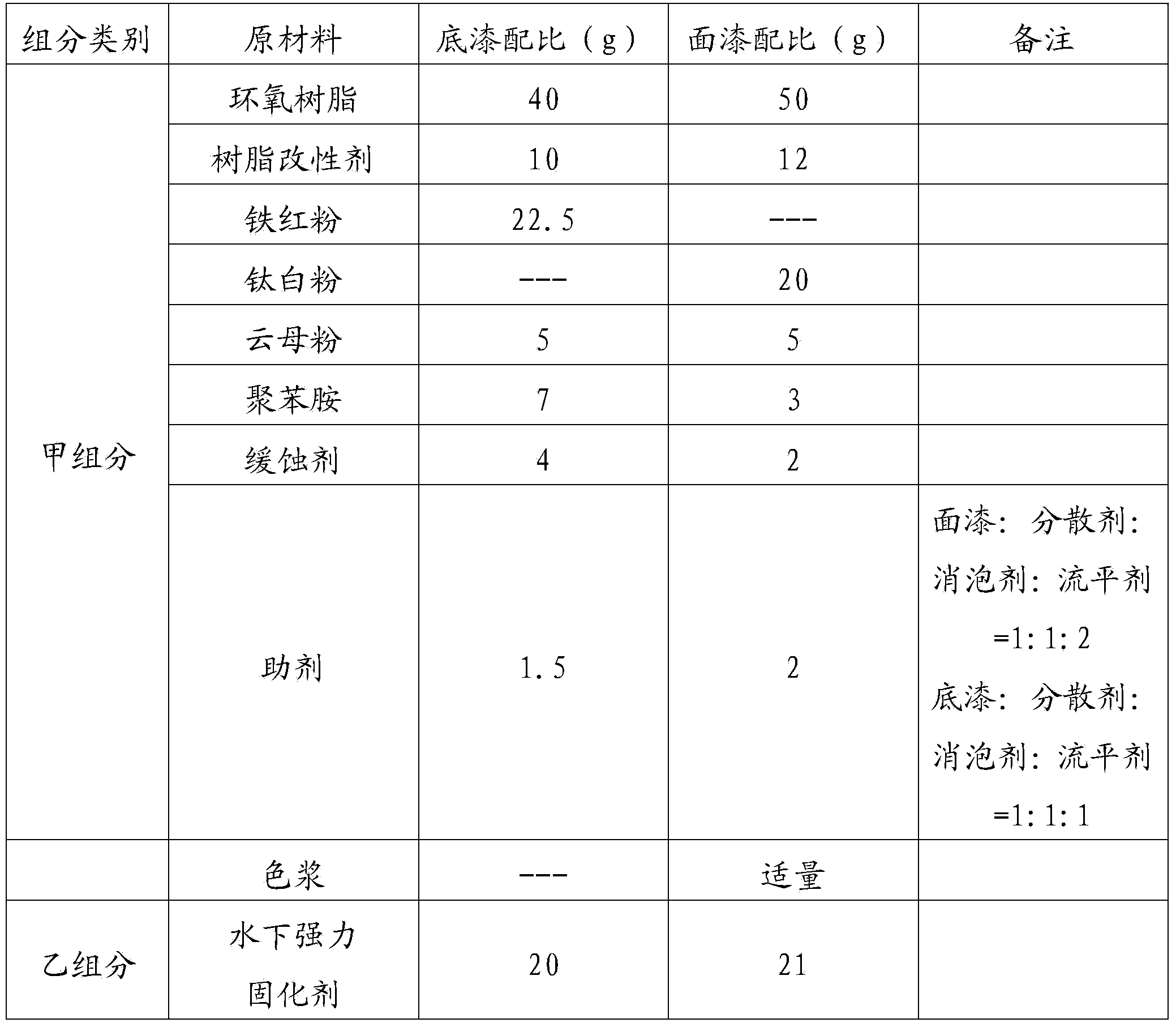

Method used

Image

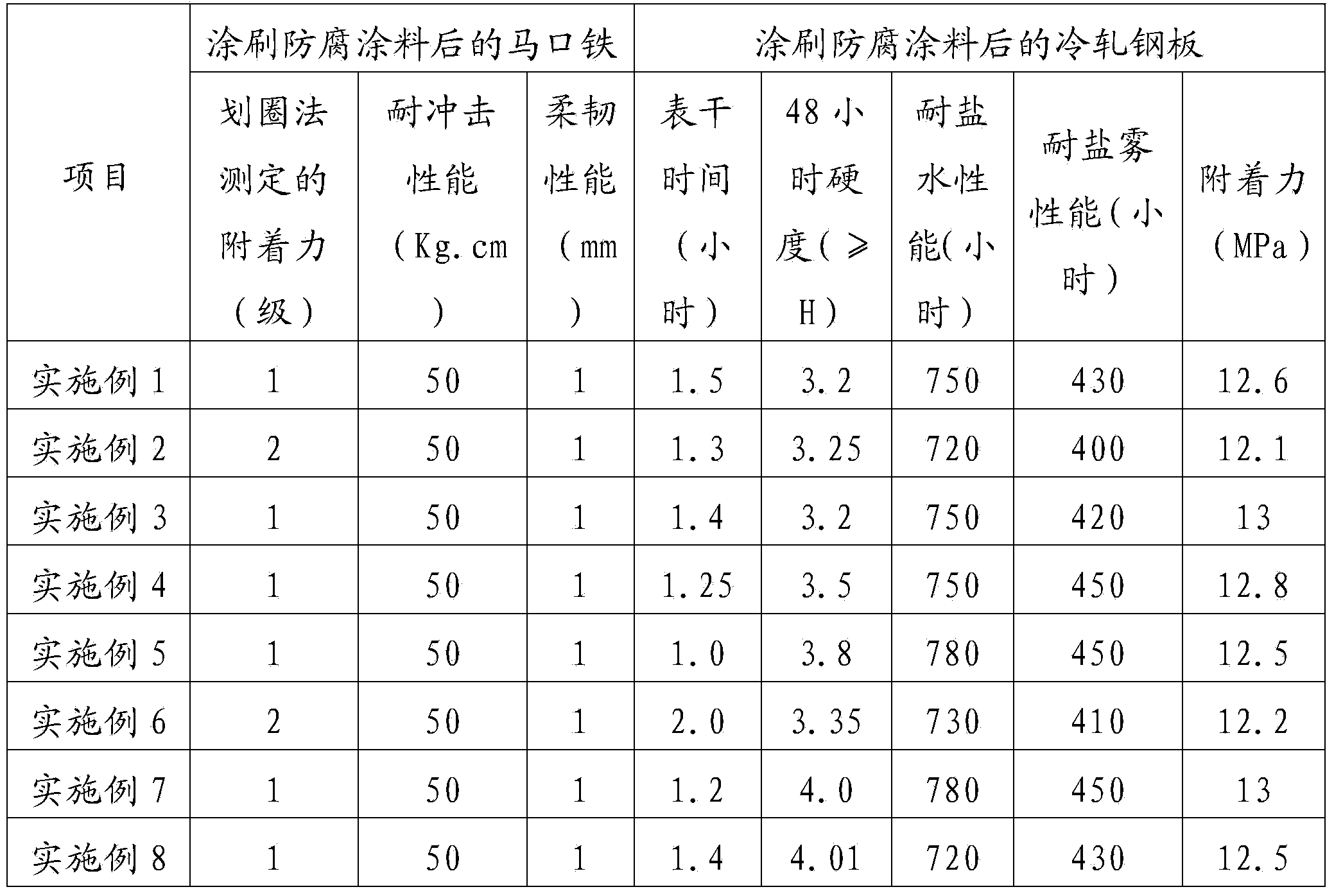

Examples

Embodiment 1

[0034] A kind of raw material of the polyaniline anticorrosion coating that is used for underwater or wet surface comprises A component and B component, and the raw material of described A component comprises epoxy resin 50g, resin modifier 8g, polyaniline 5.5g, retarder 3.5g of etchant, 1g of additives, 22g of pigments and fillers; the raw materials of component B include 20g of curing agent; the polyaniline is intrinsic polyaniline, doped with organic acids dodecylbenzenesulfonic acid and p-toluenesulfonic acid The conductive polyaniline is obtained by drying at 85°C, and its particle size is 10-12 μm.

Embodiment 2

[0036]A kind of raw material of the polyaniline anticorrosion coating that is used for underwater or wet surface comprises A component and B component, and the raw material of described A component comprises epoxy resin 35g, resin modifier 13.5g, polyaniline 3.5g, 1.5g of corrosion inhibitor, 1.5g of additives, 25g of pigments and fillers; the raw materials of component B include 19g of Mannich base epoxy resin curing agent; wherein polyaniline is intrinsic polyaniline, which is mixed with citric acid and nonyl naphthalene sulfonate Acid-doped conductive polyaniline is obtained by drying at 88°C, and its particle size is 10-15 μm; the corrosion inhibitor is made of carboxylic acid-modified polysiloxane, tetraisopropyl titanate, phytic acid It is compounded with methyldimethoxysilane according to the weight fraction ratio of 3.5:2.5:1.5:0.8.

Embodiment 3

[0038] A kind of raw material of the polyaniline anticorrosion coating that is used for underwater or wet surface comprises A component and B component, and the raw material of described A component comprises epoxy resin 55g, resin modifier 6g, polyaniline 4.5g, retarder 2.5g of etchant, 1g of additives, 21g of pigments and fillers; the raw materials of component B include 20g of curing agent; among them, polyaniline is intrinsic polyaniline, which is mixed with organic acids dodecylbenzenesulfonic acid, salicylic acid and nonyl Conductive polyaniline doped with naphthalenesulfonic acid is obtained by drying at 90°C, and its particle size is 12-14 μm; the corrosion inhibitor is made of carboxylic acid-modified polysiloxane, tetraisopropyl titanate, Phytic acid and methyldimethoxysilane are compounded according to the weight ratio of 5:4:3:1.5; the pigments and fillers include iron red powder, titanium dioxide and mica powder according to the weight ratio of 15:15 : 4 compounds...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com