Plugging agent composition, plugging agent and preparation method and application of the plugging agent

A technology of composition and plugging agent, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of low pressure bearing capacity, insufficient adhesion of plugging agent, poor plugging effect, etc., and achieve strong The effect of pressure bearing ability, good underwater adhesion ability and enhanced plugging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

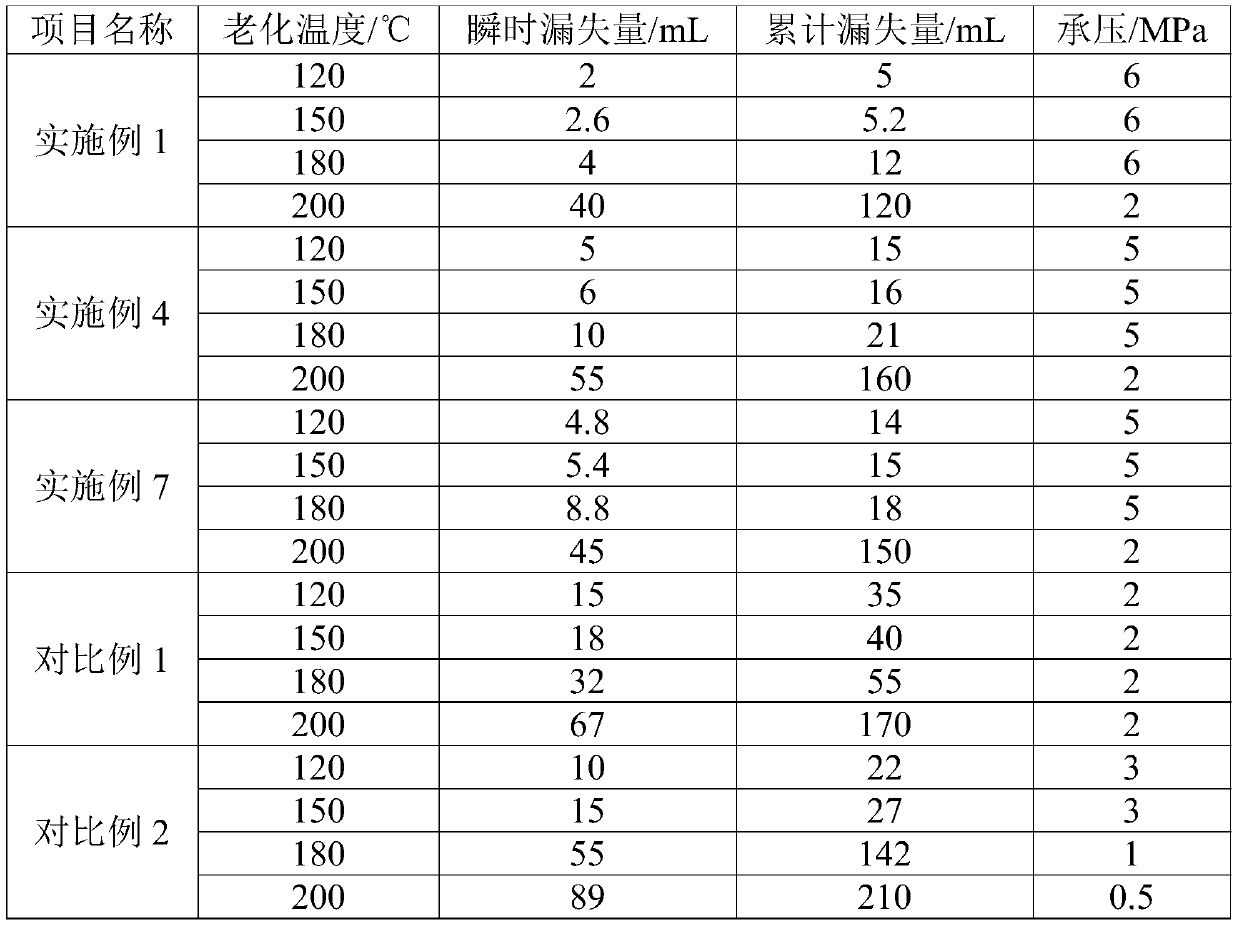

Examples

preparation example Construction

[0043] According to the second aspect of the present invention, there is provided a method for preparing a lost circulation agent, the method comprising: mixing the components of the lost circulation agent composition of the present invention and performing a polymerization crosslinking reaction.

[0044] According to the method of the present invention, the method of mixing the components of the lost circulation agent composition of the present invention is not particularly limited, for example, the components can be mixed together to perform a polymerization crosslinking reaction; water can also be mixed with any After one or two ingredients are mixed, the other ingredients are mixed together or separately. Preferably, after the first mixing of the biomimetic mussel adhesive, the nanoclay and water, the second mixing with the vinyl monomer and the crosslinking agent is performed.

[0045] The first mixing method is preferably as follows: firstly mix the water with the biomim...

Embodiment 1

[0059] Add 0.5 parts of dopamine to 100 parts of distilled water at 25°C, stir for 10 minutes with a magnetic stirrer, add 2 parts of nanoclay laponite RD, use a magnetic stirrer, stir at 25°C for 16 hours, then add 5 parts of vinyl to the above mixture A monomer (specifically acrylamide), 0.1 part of a crosslinking agent (specifically N,N-dimethylbisacrylamide), and stirred at 25°C for 10 min until the monomer and crosslinking agent are fully dissolved. Then pour the mixture into a three-necked flask, pass nitrogen gas for 30 minutes, heat to 60°C using a water bath, and heat while stirring with an electric mixer. After the temperature of the mixture reaches 60°C, add 0.1 part of initiator (specifically azobisisobutyl Amidine hydrochloride), a white gel product was obtained after 8 hours of reaction. After cooling, take out the gel, wash it, and dry it in an oven at 70°C for 16 hours to obtain a white solid product. The solid product is crushed into granules, which is the bio...

Embodiment 2

[0061] Add 1 part of dopamine to 100 parts of distilled water at 25°C, stir for 12 minutes with a magnetic stirrer, add 2.5 parts of nanoclay laponite RD, use a magnetic stirrer, stir at 25°C for 18 hours, and then add 7.5 parts of vinyl to the above mixture A monomer (specifically acrylamide), 2.5 parts of a crosslinking agent (specifically N,N-dimethylbisacrylamide), and stirred at 25°C for 15 minutes until the monomer and the crosslinking agent are fully dissolved. Then pour the mixture into a three-necked flask, pass nitrogen gas for 30 minutes, heat to 60°C using a water bath, and heat while stirring with an electric mixer. After the temperature of the mixture reaches 60°C, add 1 part of initiator (specifically azobisisobutyl Amidine hydrochloride), a white gel product was obtained after 8 hours of reaction. After cooling, take out the gel, wash it, and dry it in an oven at 70°C for 16 hours to obtain a white solid product. The solid product is crushed into granules, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com