Fermentation medium and fermentation method for producing Bleomycin A5

A fermentation medium and Pingyangmycin technology, applied in the field of industrial microorganisms, can solve the problems of high production cost and difficulty in expanding production, and achieve the effect of increasing production and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

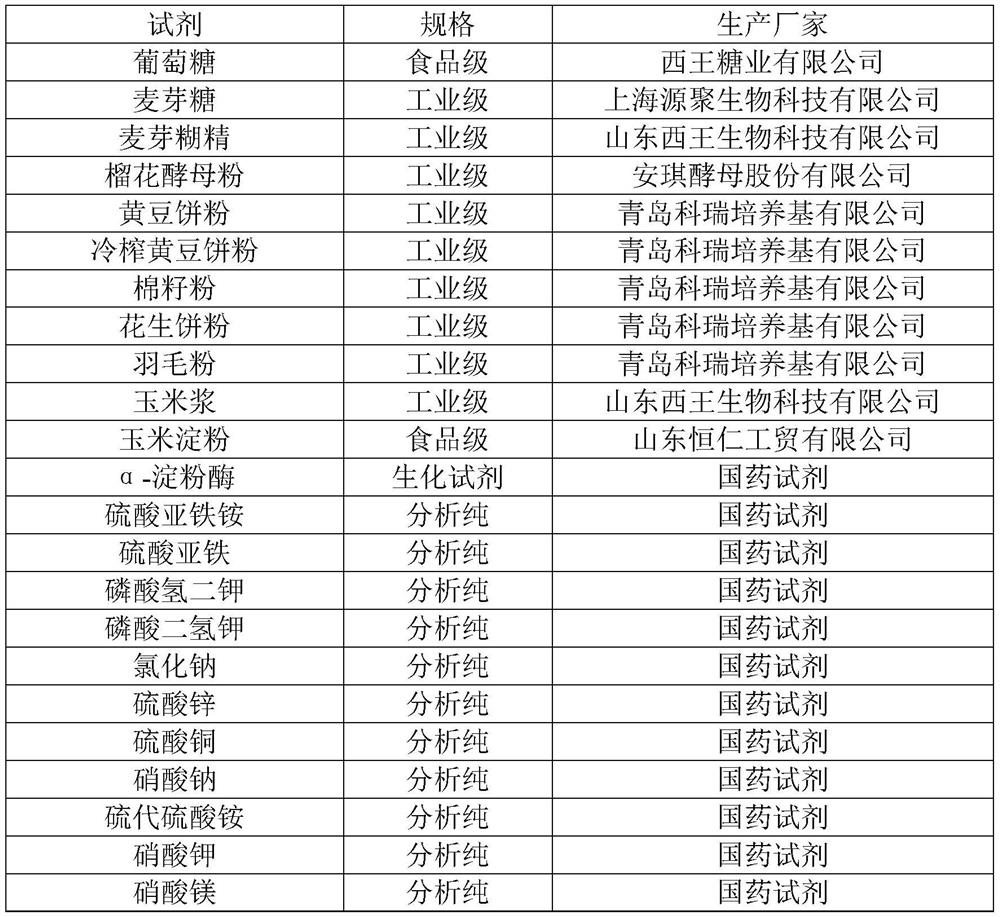

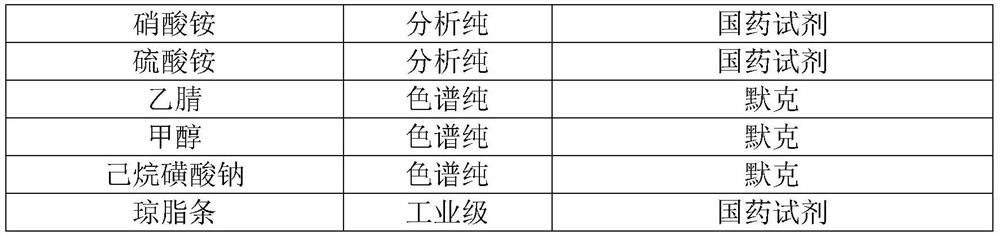

Method used

Image

Examples

Embodiment 1

[0056] Taking the formula of the basic fermentation medium (the above-mentioned medium three) as a comparison, under the condition that the components such as carbon source and inorganic salt remain unchanged, other nitrogen sources are kept constant, and the amount of corn steep liquor is explored, and the amount of corn steep liquor is changed from 0.75% to 0.75%. Adjust to 1%, shake the bottle to ferment for 8 days, and use high performance liquid phase to measure the fermentation unit.

[0057] Table 1

[0058] medium three Example 1 Amount of corn syrup (%) 0.75 1 Relative potency 1.00 1.04

[0059] The optimized formula is: 1% corn steep liquor, 3.5% cold-pressed soybean powder, 0.2% yeast powder, 0.5% glucose, 6% starch (liquefied by α-amylase), NaNO 3 0.2%, KH 2 PO 4 0.1%, ZnSO 4 ·7H 2 O 0.05% and CuSO 4 ·5H 2 O0.01%.

[0060] The titer obtained by using the above medium three for fermentation was 13 μg / ml.

Embodiment 2

[0062] Taking the basal medium formula as a control, under the condition that the carbon source, inorganic salt and other components remain unchanged, keep other nitrogen sources unchanged, explore the amount of corn steep liquor, adjust the corn steep liquor dosage from 1% to 1.2%, and shake the flask After 8 days of fermentation, the fermentation unit was measured by high performance liquid phase.

[0063] Table 2

[0064] Amount of corn syrup (%) 1 1.2 Relative potency 1.00 1.12

[0065] The optimized formula is: 1.2% corn steep liquor, 3.5% cold-pressed soybean powder, 0.2% yeast powder, 0.5% glucose, 6% starch (liquefied by α-amylase), NaNO 3 0.2%; KH 2 PO 4 0.1%, ZnSO 4 ·7H 2 O 0.05%; CuSO 4 ·5H 2 O0.01%.

Embodiment 3

[0067] Taking the basal medium formula as a control, under the condition of keeping the carbon source, inorganic salt and other components constant, and keeping other nitrogen sources constant, explore the amount of corn steep liquor, adjust the corn steep liquor dosage from 1.2% to 1.4%, and shake the flask After 8 days of fermentation, the fermentation unit was measured by high performance liquid phase.

[0068] table 3

[0069] Amount of corn syrup (%) 1.2 1.4 Relative potency 1 1.09

[0070] The optimized formula is: 1.4% corn steep liquor, 3.5% cold-pressed soybean powder, 0.2% yeast powder, 0.5% glucose, 6% starch (liquefied by α-amylase), NaNO 3 0.2%, KH 2 PO 4 0.1%, ZnSO 4 ·7H 2 O 0.05%; CuSO 4 ·5H 2 O0.01%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com