Carbon nanotube elastic core-spun yarn as well as preparation method and application thereof

An elastic core-spun yarn, carbon nanotube technology, applied in the directions of yarn, transportation and packaging, textiles and papermaking, etc., can solve the problems of limited processing length of carbon nanotube springs, no involvement, etc., to avoid performance weaknesses, enhance mechanical performance, the effect of enhancing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

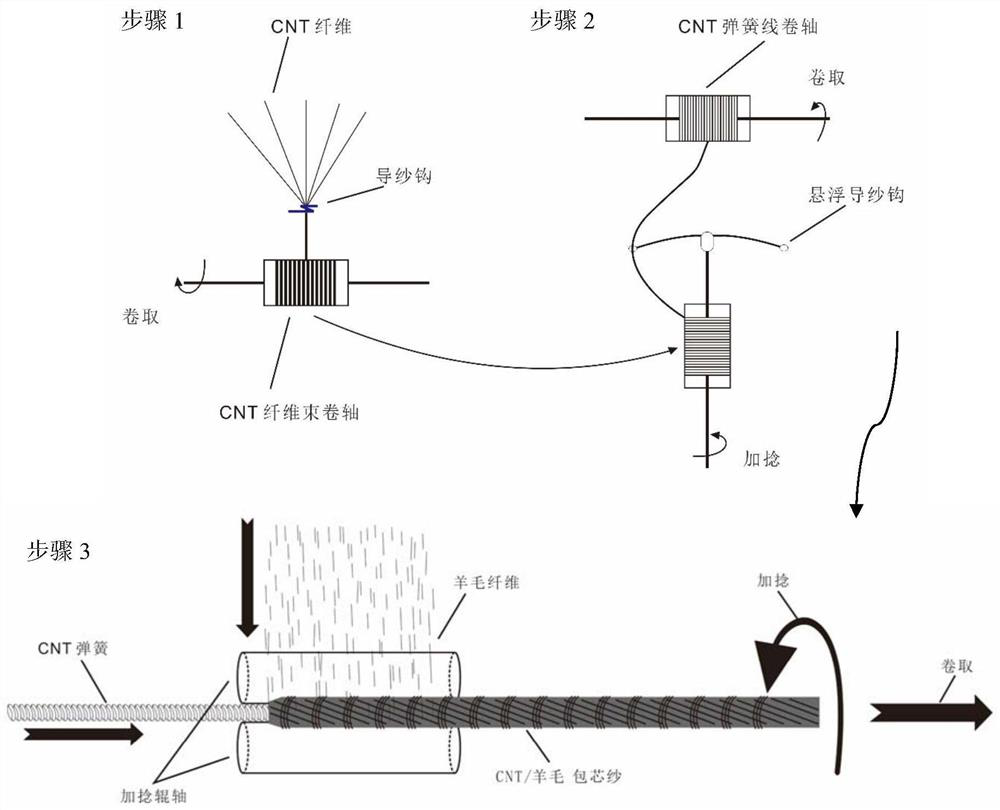

[0031] An aspect of the embodiments of the present invention provides a method for preparing a carbon nanotube elastic core-spun yarn, which includes:

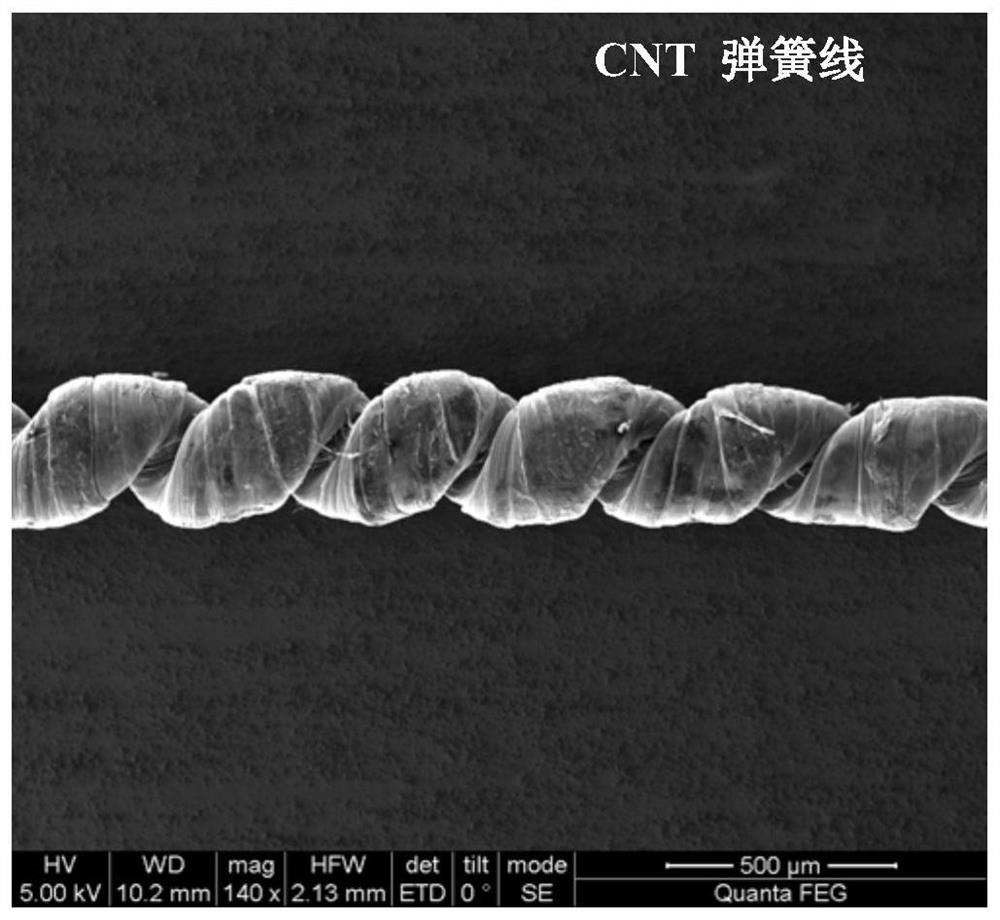

[0032] Provide carbon nanotube spring wire, which has a helical structure;

[0033] Two twisting rollers rotating in the same direction are provided, and there is a selected gap between the two twisting rollers, wherein the rotation direction of the twisting rollers is consistent with the helical structure of the carbon nanotube spring wire the same direction of the spiral;

[0034] Stretching the carbon nanotube spring wire along the length direction, and making the carbon nanotube spring wire continuously enter the selected gap, and at the same time make the short fiber flow formed by the short fiber enter the selected gap and distribute in the selected gap. The surface of the carbon nanotube spring wire is formed to form a carbon nanotube elastic core-spun yarn.

[0035] In some embodiments, the traveling direction of the...

Embodiment 1

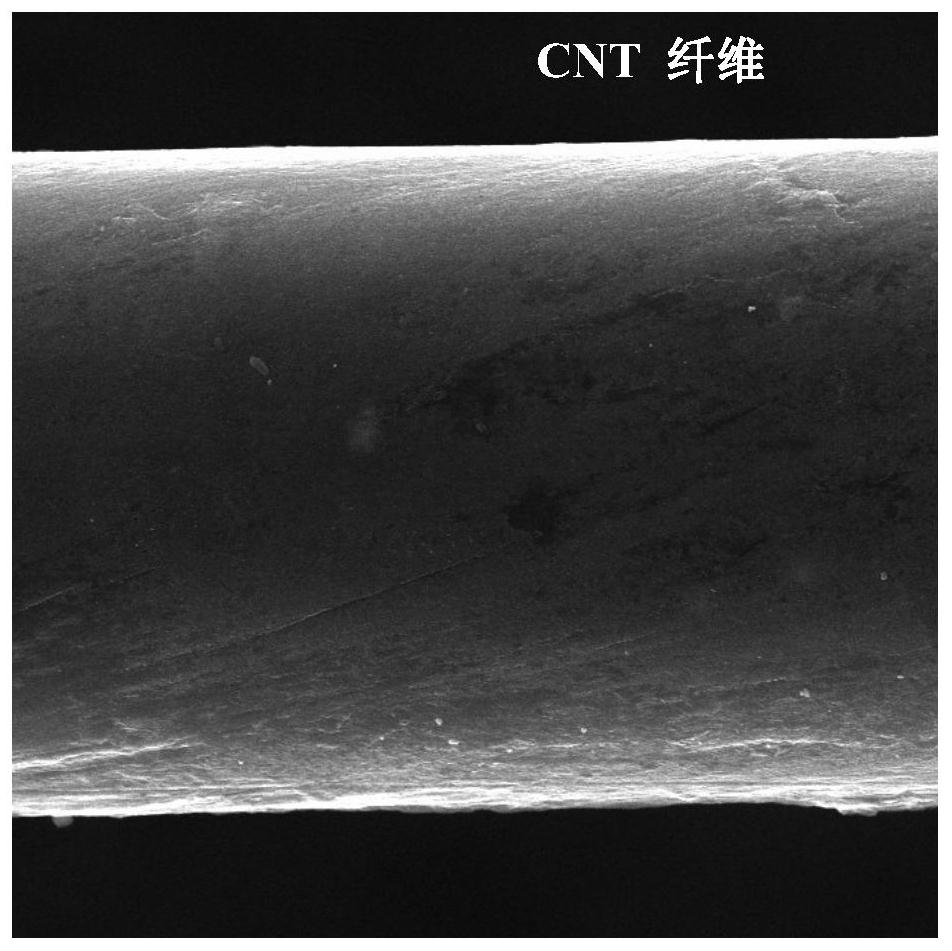

[0092] Taking 4 carbon nanotube (CNT) monofilaments and short wool fibers with a diameter of 50 μm as an example: 4 CNT monofilaments are drawn into the guide hook at the same time and continuously pass through and gather at one point to synthesize carbon nanotube fiber bundles. And collect at a speed of 10m / min; place the carbon nanotube fiber bundle on the twisting device, apply 2500T / m to it to make a continuous carbon nanotube spring, and collect it continuously on the bobbin at 0.5m / min, Each tube is 500 meters long. The CNT spring wire is introduced from the horizontal direction into the central gap formed by two twisting rollers rotating in the same direction at a speed of 0.5m / min, and the twisting roller rotates at a speed of 1000r / min. The loose fiber is wrapped around the outside of the CNT spring wire through the twisting roller at high speed to form a composite yarn, and finally collected and wound, wherein the speed of the collected and wound is 1m / min.

[0093]...

Embodiment 2

[0095] Taking 8 carbon nanotube (CNT) single fibers and short wool fibers with a diameter of 70 μm as an example: 8 CNT single fibers are simultaneously drawn into the guide hook and continuously passed through and collected at one point to synthesize carbon nanotube fiber bundles. And collect at a speed of 30m / min; place the carbon nanotube fiber bundle on the twisting device, apply 3000T / m to it to make a continuous carbon nanotube spring, and collect it continuously on the bobbin at 1m / min, every The tube length is 800 meters. The CNT spring wire is introduced from the horizontal direction into the central gap formed by two twisting rollers rotating in the same direction at a speed of 2m / min. The fiber is wrapped around the outside of the CNT spring wire through the high-speed rotation of the twisting roller to form a composite yarn, and finally collected and wound, wherein the speed of the collected and wound is 3m / min.

[0096] The linear density of the CNT spring wire o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com