High-rotating-speed oil-gas separator for turbine engine

A technology of oil-gas separator and turbine engine, which is applied in the direction of engine components, machine/engine, and engine lubrication, etc., which can solve the problems of low separation efficiency, large influence, and structural size that cannot meet the volume and weight requirements of high-speed turbine engines. Achieve high separation efficiency, improve product integration, and simplify product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

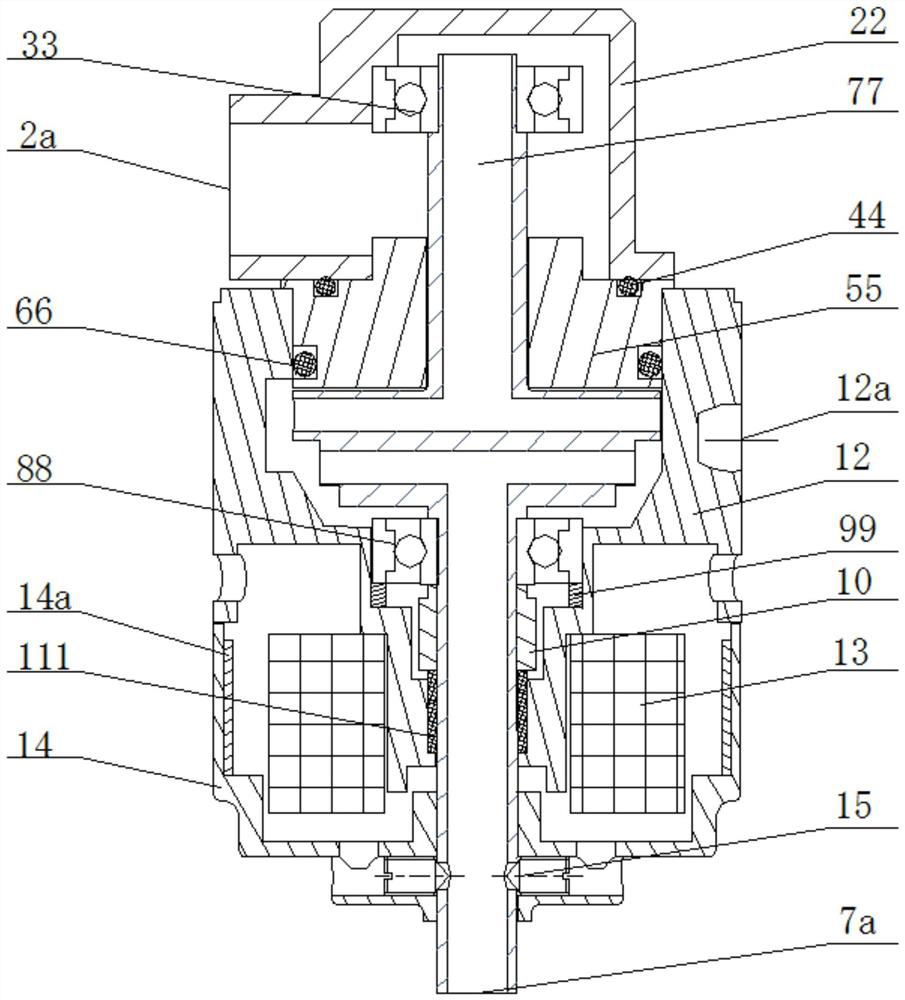

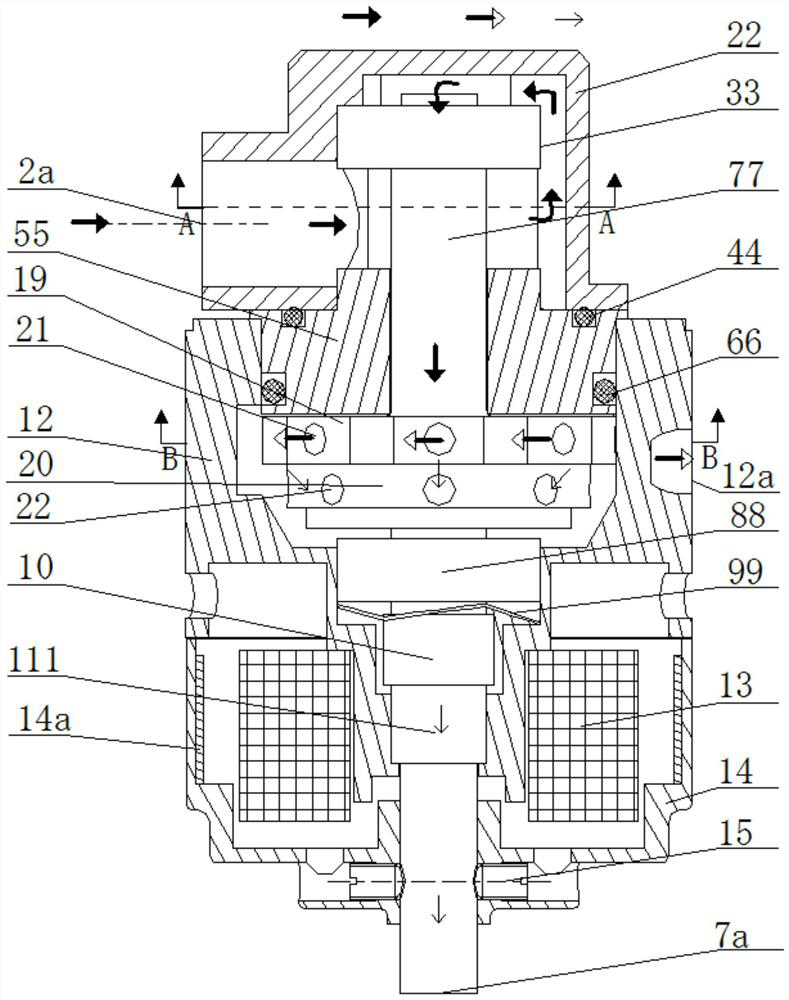

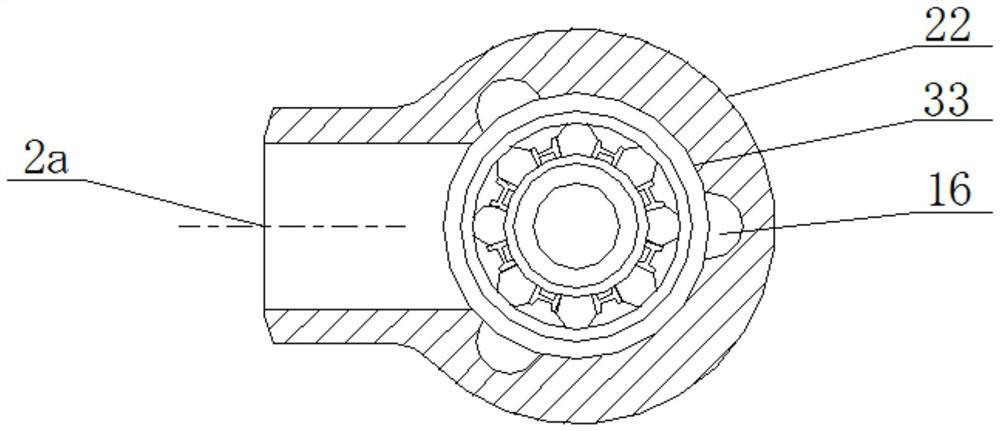

[0035] Such as figure 1 , 2 , 4, 5 and 6 A high-speed rotating oil-gas separator for a turbine engine, comprising a hollow rotating shaft 77, the upper part of the rotating shaft 77 is provided with an oil inlet chamber assembly, and the middle part of the rotating shaft 77 is provided with a separation chamber assembly, The lower part of the rotating shaft 77 is provided with a driving mechanism, and the separation chamber assembly includes a separator cavity 12 located on the outer periphery of the middle part of the rotating shaft 77, and a partition located at the middle part of the rotating shaft 77 in the separator cavity 12 layer, the first centrifugal disk 19 located at the upper part of the partition layer, the second centrifugal disk 20 located at the lower part of the partition layer, a plurality of first through holes 21 located at the outer periphery of the first centrifugal disk 19 and the A plurality of second through holes 22 on the outer periphery of the seco...

Embodiment 2

[0038] Such as Figure 4 As shown, on the basis of Example 1, the inner wall of the separator cavity 12 on the side where the oil outlet 12a is located is attached to the outer periphery of the first centrifugal disk 19 to form an abutment surface, and the The bonding surface is used as the starting point, and the second oil guiding groove 17 is provided on the inner wall of the separator cavity 12 along the direction of rotation of the rotating shaft 77 with successively increasing depths and communicates with the oil outlet 12a. The initial depth of the second oil guide groove 17 is zero, and the inner wall of the separator chamber 12 on the side where the oil outlet 12a is located is fitted to the outer periphery of the first centrifugal disk 19 to form a fitting surface without any lubricating oil thrown out. 77 rotates counterclockwise, the deeper the second oil guide groove 17 is, it is beneficial to the collection and flow discharge of lubricating oil subjected to centr...

Embodiment 3

[0040] Such as figure 1 , 2 , 5 and 6, on the basis of Example 1, the rotating shaft 77, the first centrifugal disc 19, the barrier layer and the second centrifugal disc 20 are integrally formed, and the first The centrifugal disc 19 communicates with the rotating shaft 77 on the upper part of the barrier layer, and the second centrifugal disc 20 communicates with the rotating shaft 77 on the lower part of the barrier layer. It is convenient for processing and assembly, and the product structure is simple.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com