Compound water pump

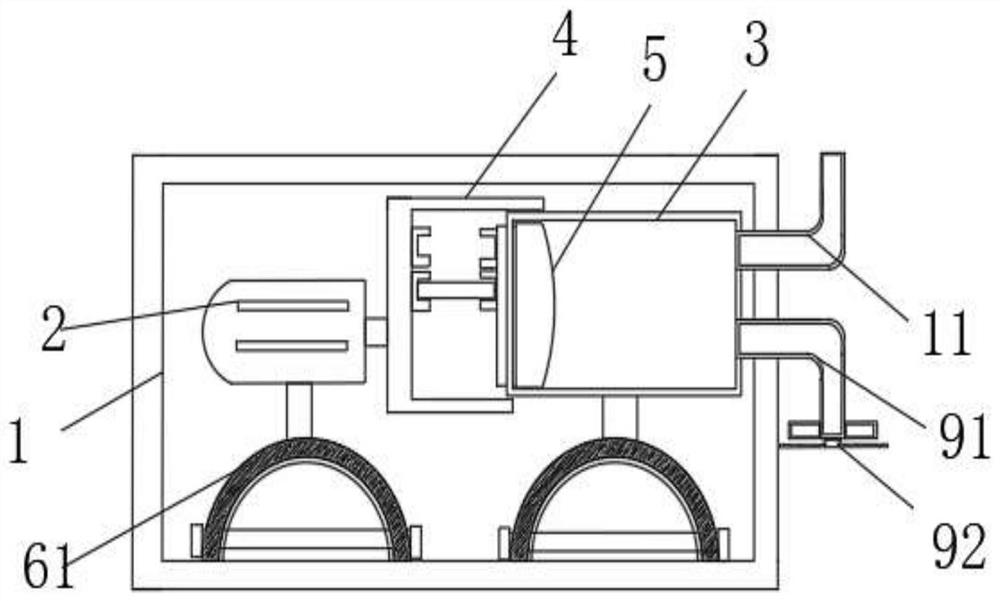

A technology of compound water pump and pump body, applied in the direction of variable capacity pump parts, pumps, pump components, etc., can solve the problems of inconvenient disassembly and assembly of fixed structures, poor anti-pollution ability, and humid environment, and achieves convenient disassembly and adjustment, reducing Ground contact, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0044] As an embodiment of the present invention, the inner surface of the rectangular frame body 1 is close to one side and the long groove 7 on the outer surface of the upper end of the rectangular frame body 1, and the upper and lower two long grooves 7 are movably connected with a frame Plate mechanism 8, and frame-plate mechanism 8 is made up of straight plate 81 and inclined plate 82, and the outer surface of one side of described straight plate 81 offers rectangular groove 83, and inclined plate 82 is movably connected in the inside of rectangular groove 83, and described inclined plate A hinge 84 is movably connected between the 82 and the rectangular groove 83, and the other side outer surface of the straight plate 81 is provided with a cooling hole 85. After the body is installed, the frame plate mechanism 8 is placed on one side of the rectangular frame body 1, The rectangular frame body 1 is airtight, which can protect the motor 2, the pump body 3 and the whole devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com