Modified lignocellulose diaphragm for lithium ion battery, preparation method and application thereof

A lignocellulose, lithium-ion battery technology, applied in the direction of electrolyte storage battery manufacturing, secondary battery, battery pack parts, etc., can solve the problems of poor battery electrochemical performance, high preparation cost, cumbersome production technology, etc. Electrochemical performance, cost savings, overcoming the effect of poor thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 一种带有改性天然木质纤维素隔膜的锂离子电池,具体制备方法如下:

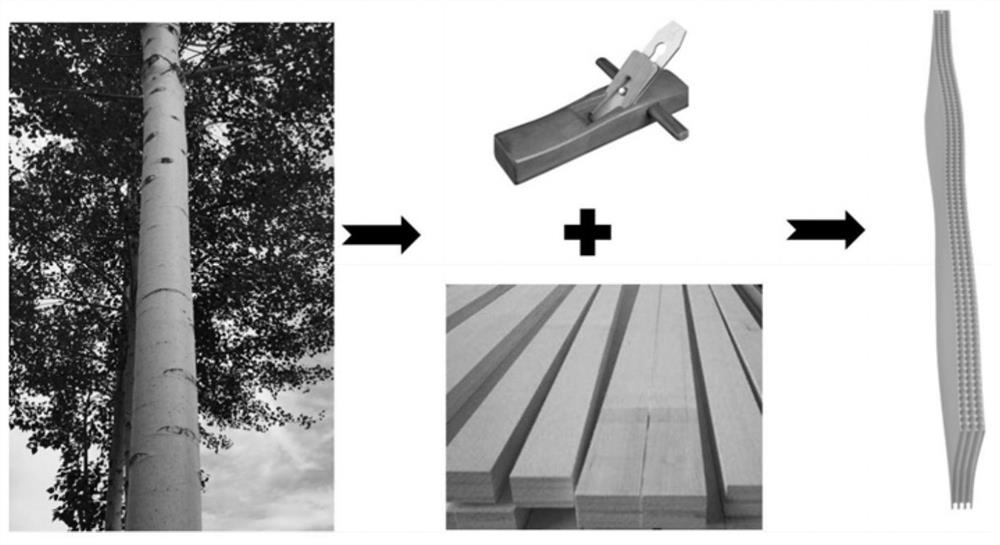

[0042] (1)将预先挑选的白杨木减薄至厚度为50μm的薄膜,制备过程示意图如 figure 1 shown;

[0043] (2)将上述得到的天然木材薄膜在碱溶液中进行预处理,具体过程如下:将3g氢氧化钾溶解于60mL去离子水中,搅拌10min得到均一的溶液;再称取2g亚硫酸钠加入上述溶液中,搅拌10min后,得到均一溶液。 再将天然木材薄膜浸没在上述溶液中,置于真空烘箱中,在负压下,使得混合碱液充分浸泡木材薄膜,半小时后取出,转移到反应釜中,100℃下反应5h后取出,反复用去离子水洗涤至中性为止。 室温下用玻璃片夹持,逐渐缓慢干燥,或者先置于冰箱(-10℃)中预先冷冻0.5h后再置于冷冻干燥机(-30℃)中冷冻干燥12h,得到处理好的白杨木 film.

[0044] (3)制备磷酸铁锂极片及电池的组装的过程如下:将磷酸铁锂、炭黑、PVDF按照8:1:1的比例。加入适量NMP后调浆搅拌5h,手工涂膜,之后80℃真空干燥过夜,得到的极片卡成直径为14mm的圆形电极片。将锂片、电解液、隔膜和裁切好的电极片组装成基于天然木材薄膜的2032纽扣锂离子电池。

[0045] (4)磷酸铁锂极片厚度为50μm左右。

[0046] 经检测,最终所得的基于白杨木薄膜的锂离子电池表现出与使用商业化聚烯烃隔膜相比拟的性能。

[0047] 本发明所涉及到的天然木质纤维素薄膜的制备过程简便,如 figure 1 所示,可以看出方法非常简单,首先将天然木材用刨子等机械加工方法切成微米级薄膜。

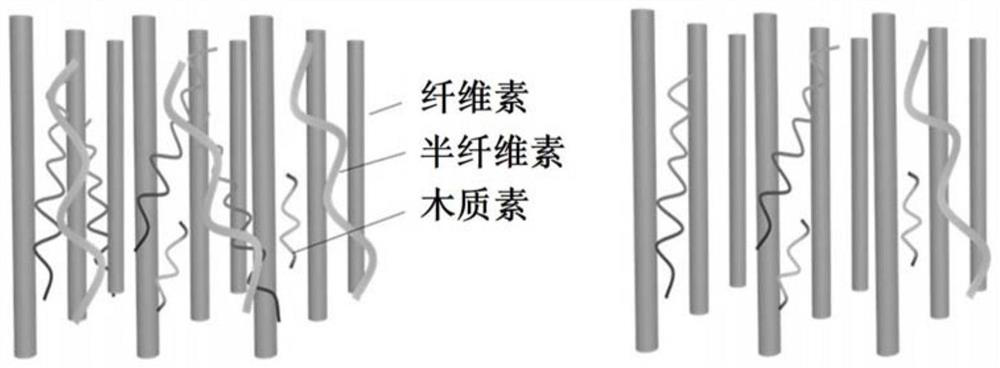

[0048] 为了使天然薄膜更加有助于锂离子的扩散,我们进一步脱除部分木质素和半纤维素,使得纤维素之间有更多的孔隙容纳更多的电解液和加速锂离子的传递( figure 2 ).

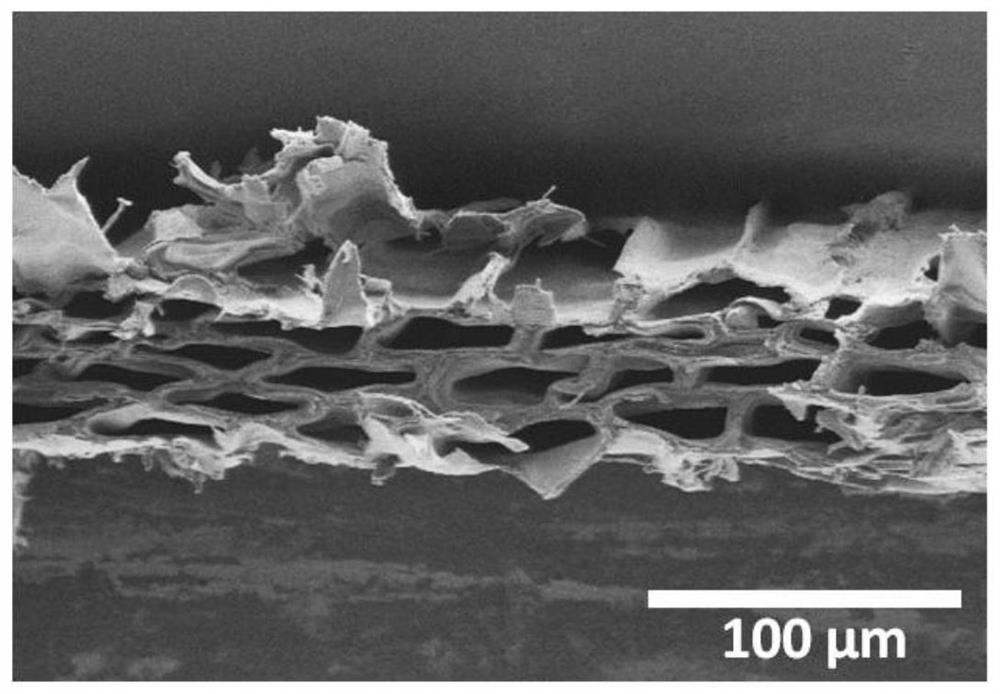

[0049] 电池隔膜的微观结构与其电化学性能息息相关,进一步地,选取三种不同的木头:白杨木、松木、椴木研究其结构与电化学性能之间的关系,通过扫描电镜照片(图3)可以看出松木的孔道比较均一且相对较大,白杨木是典型的分级多孔结构,而椴木相对来说较为致密;并且三种木质纤维素隔膜表现出不同的颜色( Figure 4 ).

[0050] 进一步通过锂对称电池测试了三种隔膜的离子电导率...

Embodiment 2

[0056] 一种带有改性天然木质纤维素隔膜的锂离子电池,具体制备方法如下:

[0057] (1)将预先挑选的椴木减薄至150μm左右。

[0058] (2)将上述得到的椴木薄膜在碱溶液中进行预处理,具体过程如下:在90ml去离子水中,加入6g氢氧化钾溶解于90mL去离子水中,搅拌30min得到均一的溶液;再称取4.5g亚硫酸钠加入上述溶液中,搅拌30min后,得到均一溶液。再将天然木材薄膜,浸没在上述溶液中,置于真空烘箱中,在负压下,使得混合碱液充分浸泡木材隔膜,半小时后取出,转移到反应釜中,120℃下反应12h后取出,反复用去离子水洗涤至中性为止。室温下用玻璃片夹持,逐渐缓慢干燥,或者先置于冰箱(-20℃)中预先冷冻12h后再置于冷冻干燥机(-40℃)中冷冻干燥24h,得到处理好的椴木薄膜。

[0059] (3)制备磷酸铁锂极片及电池的组装的过程如下:将磷酸铁锂、炭黑、PVDF按照7:2:1的比例。加入适量NMP后调浆搅拌10h,手工涂膜,之后100℃真空干燥过夜,得到的极片卡成直径为16mm的圆形电极片。将锂片、电解液、隔膜和裁切好的电极片组装成基于天然椴木薄膜的2032纽扣锂离子电池。

[0060] (4)磷酸铁锂极片厚度为100μm左右。

[0061] 经检测,最终所得的基于椴木薄膜的锂离子电池表现出与使用商业化聚烯烃隔膜相比拟的性能。

Embodiment 3

[0063] 一种带有改性天然木质纤维素隔膜的锂离子电池,具体制备方法如下:

[0064] (1)将预先挑选的天然松木减薄至300μm左右。

[0065] (2)将上述天然木材薄膜在碱溶液中进行预处理,具体过程如下:将8g氢氧化钾溶解于120mL去离子水中,搅拌60min得到均一的溶液;再称取8g亚硫酸钠加入上述溶液中,搅拌60min后,得到均一溶液。再将天然木材薄膜,浸没在上述溶液中,置于真空烘箱中,在负压下,使得混合碱液充分浸泡木材隔膜,半小时后取出,转移到反应釜中,140℃下反应24h后取出,反复用去离子水洗涤至中性为止。室温下用玻璃片夹持,逐渐缓慢干燥,或者先置于冰箱(-30℃)中预先冷冻24h后再置于冷冻干燥机(-60℃)中冷冻干燥48h,得到处理好的松木薄膜。

[0066] 采用冷冻干燥的方式的对天然松木薄膜进行干燥,数天后得到处理好的天然木材薄膜。

[0067] (3)制备磷酸铁锂极片及电池的组装的过程如下:将磷酸铁锂、炭黑、PVDF按照6:3:1的比例。加入适量NMP后调浆搅拌24h,手工涂膜,之后120℃真空干燥过夜,得到的极片卡成直径为18mm的圆形电极片。将锂片、电解液、隔膜和裁切好的电极片组装成基于天然松木薄膜的2032纽扣锂离子电池。

[0068] (4)磷酸铁锂极片厚度为250μm左右。

[0069] 经检测,最终所得的基于天然松木薄膜的锂离子电池表现出与使用商业化聚烯烃隔膜的锂电池相比拟的性能。

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com