Method for soaking and enriching gamma-aminobutyric acid in coffee leaves by ultrasonic waves in cooperation with sodium glutamate

A technology of sodium glutamate and aminobutyric acid, which is applied in the field of physical processing, can solve the problems of lack of GABA enrichment research and methods that have not been studied, and achieve the effect of simple operation, significant effect, and improved inhibitory activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

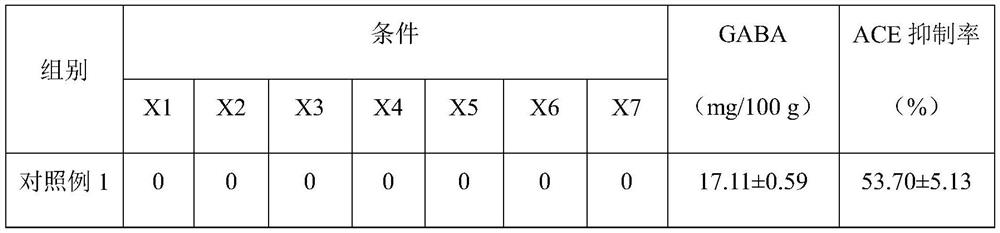

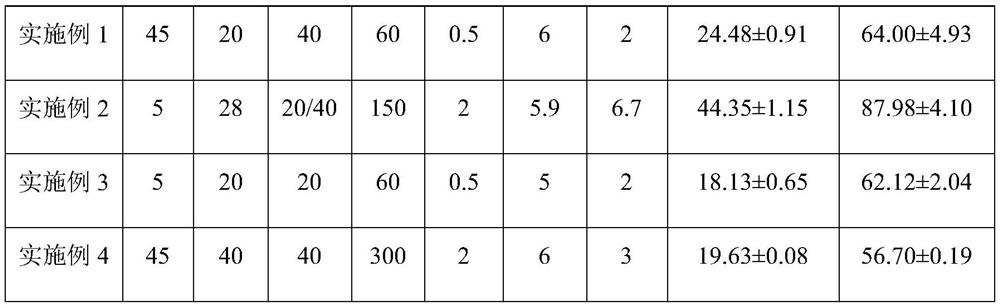

Examples

Embodiment 1

[0037] (1) Sorting the fresh coffee leaves, removing dry leaves, bad leaves and leaf stalks, and obtaining the fresh coffee leaves after screening;

[0038] (2) Sodium glutamate is added to water, after mixing and dissolving, the pH value is adjusted to 6 to obtain a 0.5% sodium glutamate aqueous solution;

[0039] (3) Soak the screened fresh coffee leaves in an aqueous solution of sodium glutamate, while adjusting the ultrasonic temperature to 20°C, the ultrasonic frequency to 40KHz, and the ultrasonic power to 60W for ultrasonic treatment, and the ultrasonic time is 45 minutes;

[0040] (4) Wash the coffee leaves treated with step (3) with clear water and drain, then let stand at 28°C for 2h,

[0041] (5) Freeze-dry the coffee leaves treated in step (4) with a vacuum degree of <10MPa and a temperature of <-50°C. After freeze-drying, enriched coffee leaves are obtained, which are then pulverized by a pulverizer and filtered through a 60-mesh sieve. Finally, the enriched coff...

Embodiment 2

[0046] The test operation process is the same as in Example 1, except that the ultrasonic time is 5min, the ultrasonic temperature is 28°C, the ultrasonic frequency is 20 / 40KHz, the ultrasonic power is 150W, the concentration of sodium glutamate solution is 2%, the pH value is 5.9, and the standing time is 6.7h. See Table 1.

Embodiment 3

[0048] The test operation process was the same as that in Example 1, except that the ultrasonic time was 5 minutes, the ultrasonic temperature was 20° C., the ultrasonic frequency was 20 KHz, the ultrasonic power was 60 W, the concentration of sodium glutamate solution was 0.5%, the pH value was 5, and the standing time was 2 hours. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com