Perforated penetrable stirring paddle of coating machine

A stirring paddle, through-type technology, applied in mixers, transportation and packaging, mixers with rotating containers, etc., can solve problems such as aggravating the wear of coated products, uneven coating, and no solution to coating uniformity. , to reduce the occurrence of edge knocking, ensure coating uniformity, and improve coating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

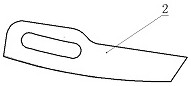

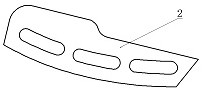

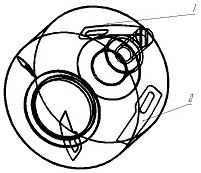

[0023] Such as Figure 1 to Figure 6 As shown, the present invention is an agitating paddle of an open-hole traversable coating machine. The agitating paddle 2 is evenly and alternately distributed on the inner wall of the pot body 1 in a Z-shaped inclination, and there is no gap between the agitating paddle 2 and the pot body 1. Stirring The diversion distal end of the paddle 2 rises and bends toward the direction of flow, and the side elevation of the stirring paddle 2 has traversable openings.

[0024] As a further improvement of the above technical solution, the side elevation of the paddle body of the stirring paddle 2 has different numbers of holes accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com