Industrial solid waste treatment equipment

A treatment equipment and industrial technology, applied in the direction of mechanical equipment, grain treatment, cleaning methods and utensils, etc., can solve the problem of low crushing degree of solid waste, facilitate transportation and treatment, improve treatment efficiency, and reduce dust flying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

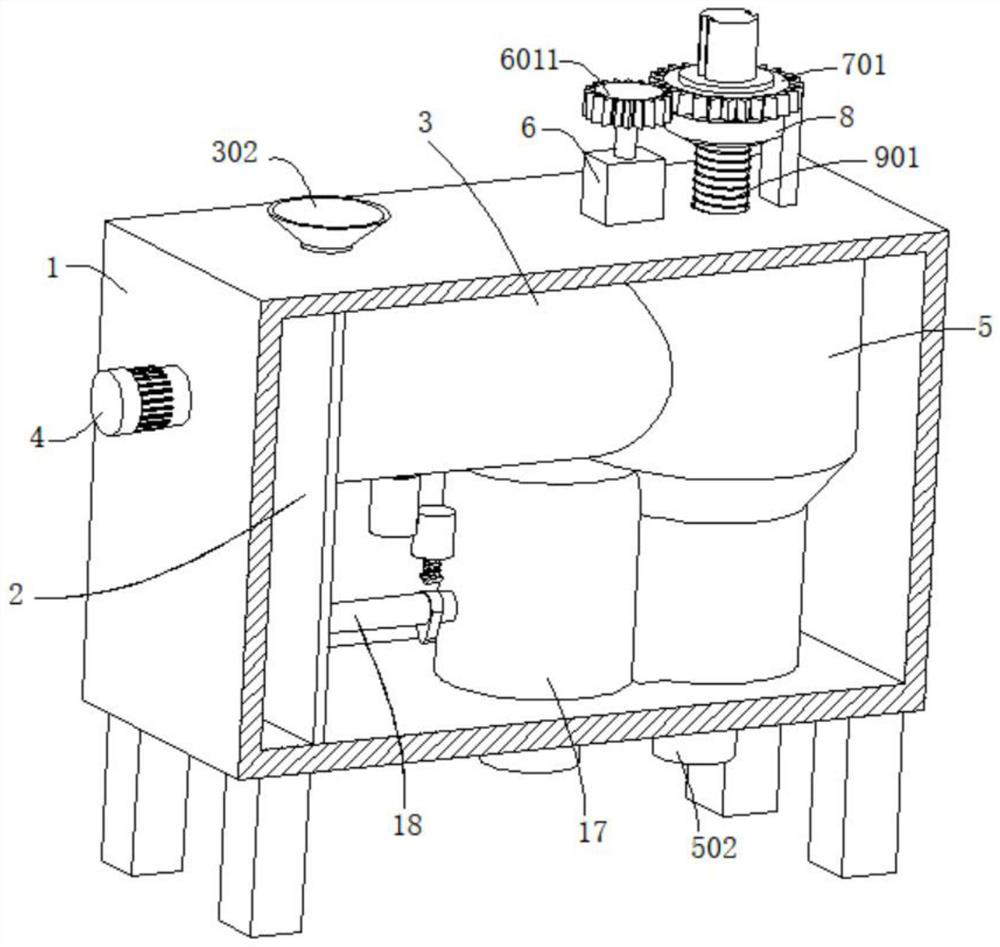

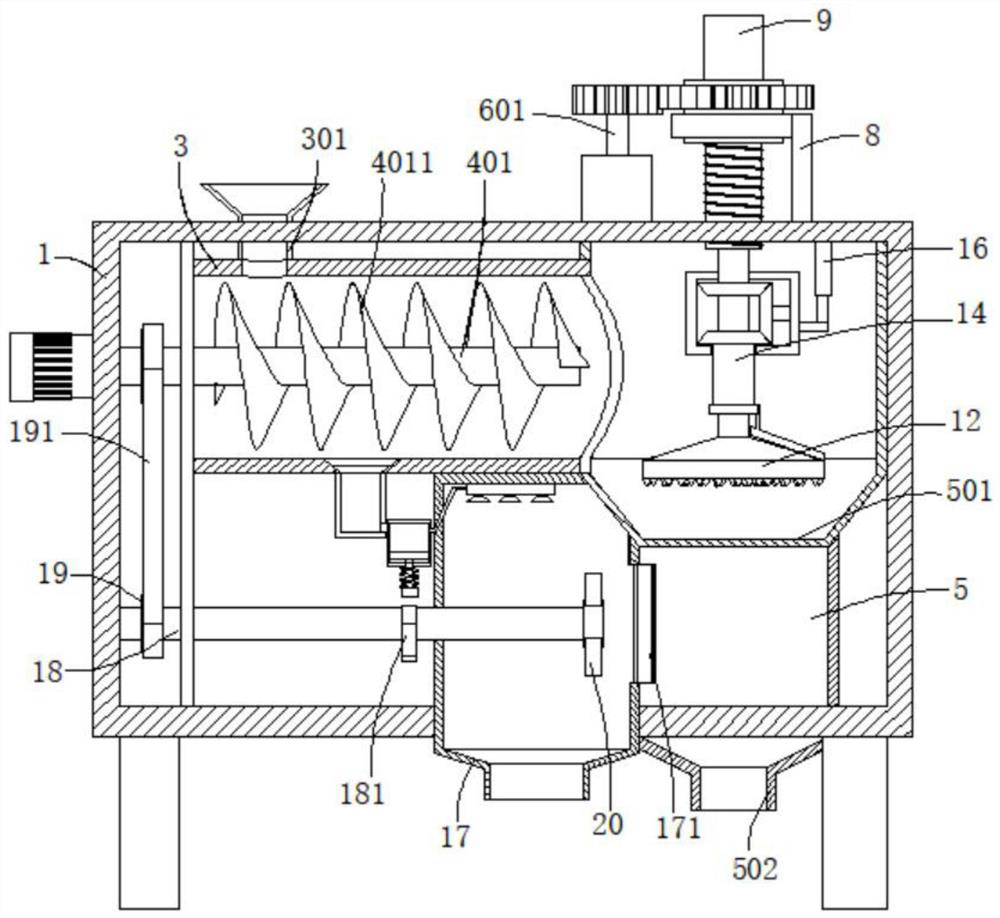

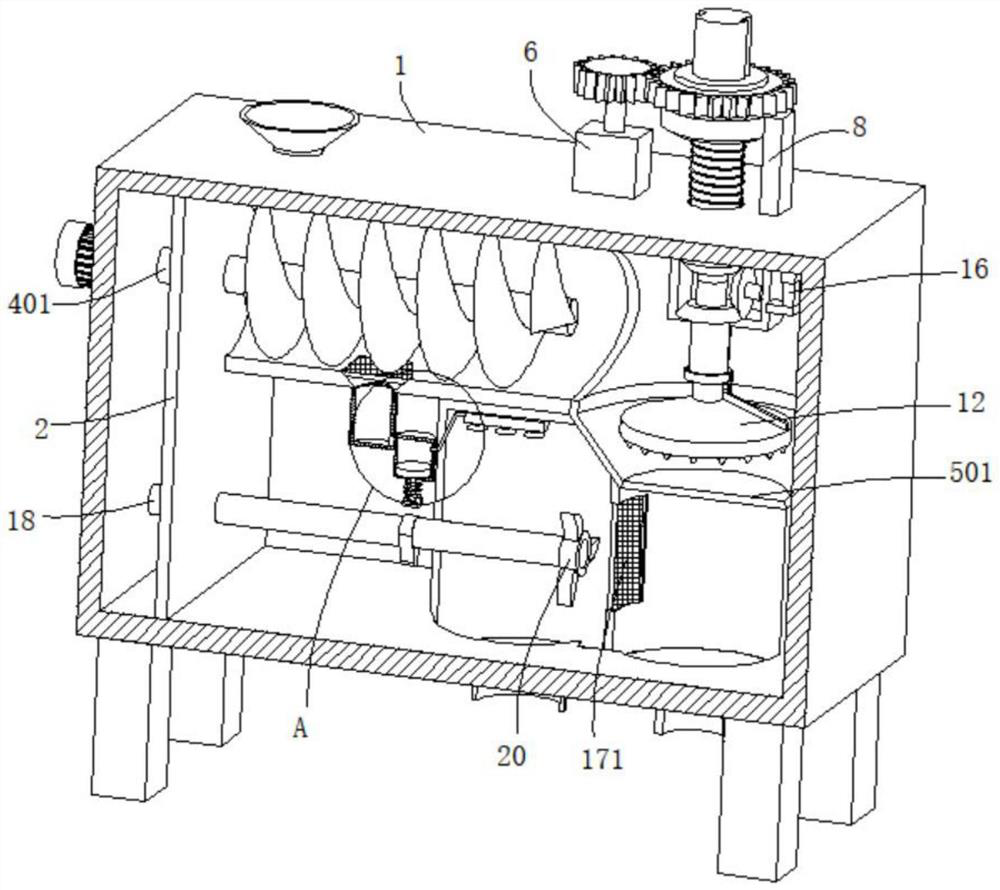

[0035] refer to Figure 1-5, a kind of industrial solid waste treatment equipment, comprising a working box 1, the inner wall of the working box 1 is connected with a partition 2, the outer wall of the partition 2 is connected with a conveying pipe 3, the top outer wall of the conveying pipe 3 is connected with a feeding pipe 301, and the feeding The end of the pipe 301 away from the conveying pipe 3 passes through the working box 1 and is connected with a feed port 302. The inner wall of the working box 1 is connected with a processing box 5. The inner wall of the processing box 5 is provided with a filter plate 501. The processing box 5 passes through the working box 1. The bottom of the working box 1 is connected with a discharge port 502 extending outward, the processing box 5 communicates with the conveying pipe 3, the top outer wall of the working box 1 is connected with a second motor 6, and the output end of the second motor 6 is connected with a second rotating shaft 6...

Embodiment 2

[0042] refer to Figure 2-4 , a kind of industrial solid waste treatment equipment, which is basically the same as that of Embodiment 1. Furthermore, the outer wall of the fixed rod 10 is connected with a first bevel gear 13, and the outer wall of the fixed rod 10 is connected with a fixed tube 14 through a first bearing for rotation, and the fixed The outer wall of the tube 14 is connected with a second bevel gear 141, the outer wall of the fixed tube 14 is connected with a scraper 142, the scraper 142 moves against the outer wall of the crushing plate 12, and the fixed rod 10 and the outer wall of the fixed tube 14 pass through the second bearing and the third bearing respectively Rotation is connected with same fixed mount 15, is connected with telescopic plate 16 between the top inwall of fixed mount 15 and work box 1, is connected with connecting rod 151 in fixed mount 15 inwalls, is connected with the 3rd bevel gear 152 on connecting rod 151 outer walls, the 3rd Two oute...

Embodiment 3

[0045] refer to Figure 1-7 , a kind of industrial solid waste treatment equipment, which is basically the same as that of Embodiment 1, furthermore, the outer wall of the treatment box 5 is connected with a waste water tank 17, the waste water tank 17 is connected to the treatment box 5, and the waste water tank 17 is connected to the treatment box 5 A first filter screen 171 is connected therebetween.

[0046] The inner wall of the working box 1 is rotatably connected with a rotating rod 18, and the rotating rod 18 is rotatably connected in the waste water tank 17. The rotating rod 18 and the outer wall of the first rotating shaft 401 are connected with a matching synchronous wheel 19, and a synchronous wheel 19 is connected between the two synchronous wheels 19. The belt 191 and the outer wall of the rotating rod 18 are connected with fan blades 20 , and the fan blades 20 are placed in the waste water tank 17 .

[0047] The bottom of delivery pipe 3 is connected with water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com