Diamond compact and preparation method thereof

A technology of diamond composite sheet and composite sheet, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems affecting the service life and loss of coating tools, and achieve enhanced wear resistance and enhanced use Longevity and the effect of enhancing the holding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

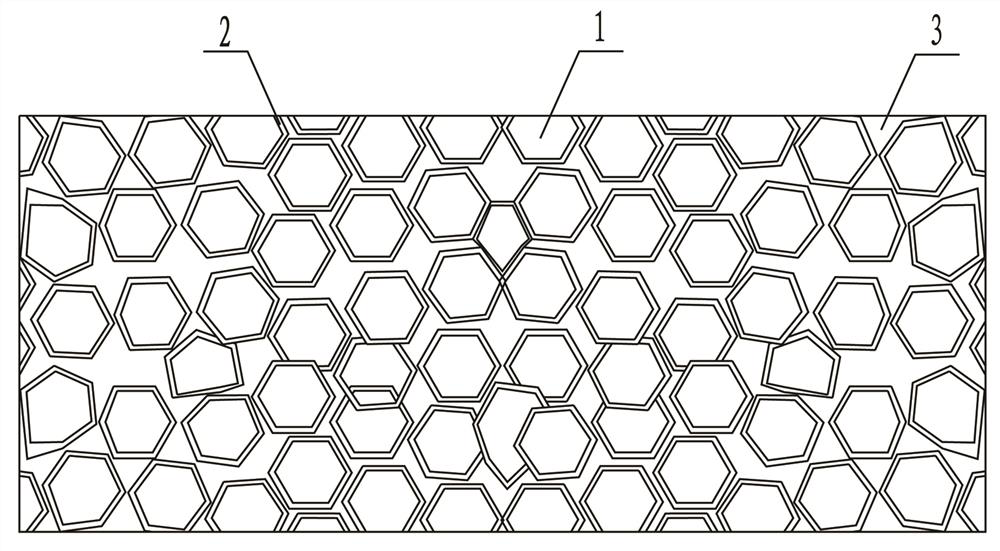

[0043] see figure 1 with figure 2 , the present embodiment provides a diamond composite sheet, which is mainly composed of polycrystalline diamond particles 1, a wear-resistant metal compound coating 2 formed on the surface of the polycrystalline diamond particles and filled in adjacent wear-resistant metal compound coatings 2 Metal bond 3 composition. That is, the diamond composite sheet provided in this embodiment is mainly composed of polycrystalline diamond composite particles and a metal bond 3 connecting adjacent polycrystalline diamond composite particles, and the polycrystalline diamond composite particles are composed of polycrystalline diamond particles 1 It is composed of wear-resistant metal compound coating 2 formed on the surface of polycrystalline diamond particles.

[0044] An embodiment of the present invention provid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com