Multi-sensor welding equipment carrying robot and adopting bidirectional camera shooting

A multi-sensor, welding equipment technology, applied in welding equipment, laser welding equipment, metal processing equipment and other directions, can solve the problem that the acoustic signal detection method is easily affected by nozzle airflow and environmental noise, application limitations, etc., to improve welding quality. , High degree of automation, good welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

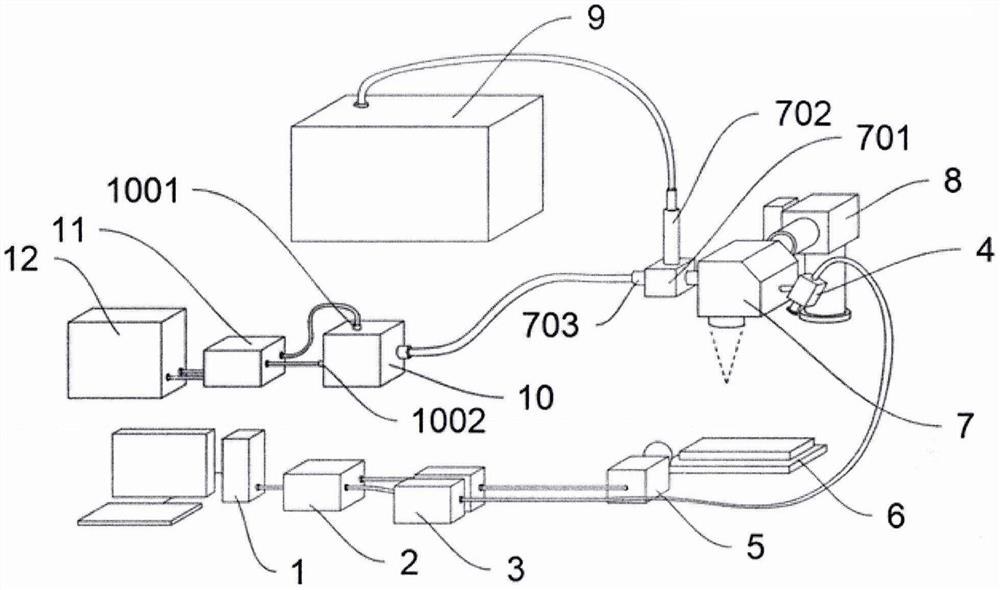

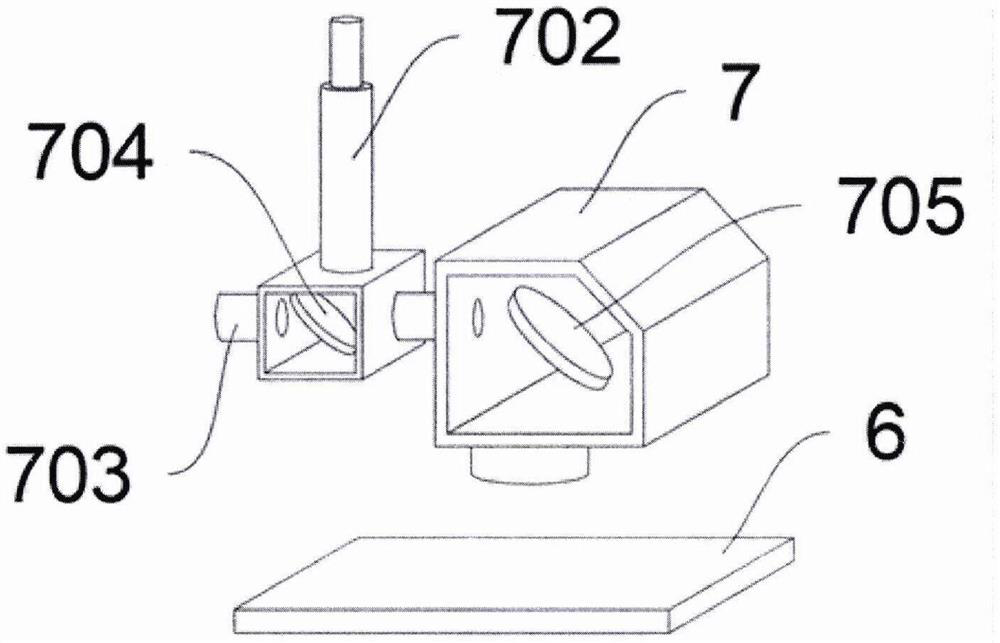

[0028] as attached figure 1 to attach Figure 4 Shown:

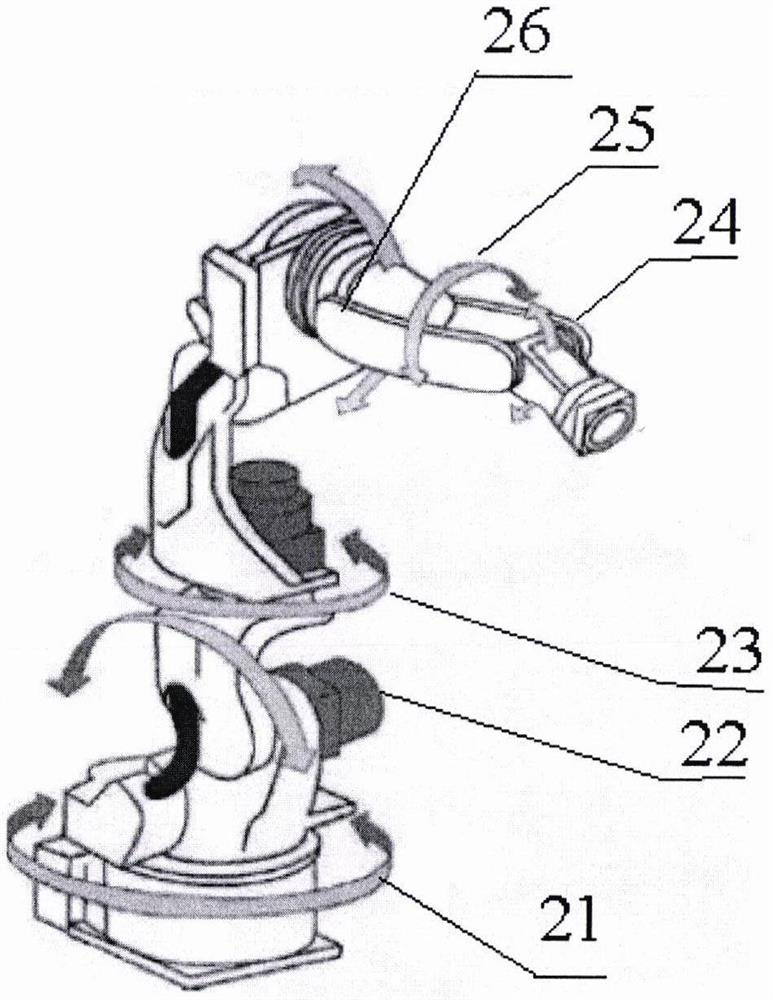

[0029] The present invention provides a multi-sensor welding device with a robot and two-way camera, including a controller 1 and a scanner laser head 7; the controller 1 is connected with a signal synchronizer 2; Data processor 3; two groups of data processors 3 are respectively provided with lines connected to a monochrome camera system 4 and a color camera 5; wherein, one side of the color camera 5 is provided with a metal plate 6, and the metal plate 6 is provided with a metal plate waiting for laser welding. workpiece, and the front end of the color camera 5 is provided with a filter; the front end of the monochrome camera system 4 is provided with a near infrared filter; one side of the scanner laser head 7 is connected with a six-axis robot 8; Also includes a refraction bin 701, a laser beam end 702, and a reflection area 703; one side of the scanner laser head 7 is connected with a refraction bin 701; the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com