Anti-collision detection system for chemical mechanical grinding equipment

A chemical-mechanical, anti-collision technology, used in grinding/polishing equipment, grinding machine tools, grinding devices, etc., can solve the problems of collision, wafer surface damage, metal debris falling, etc., to avoid fatal damage, Enhanced stability and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

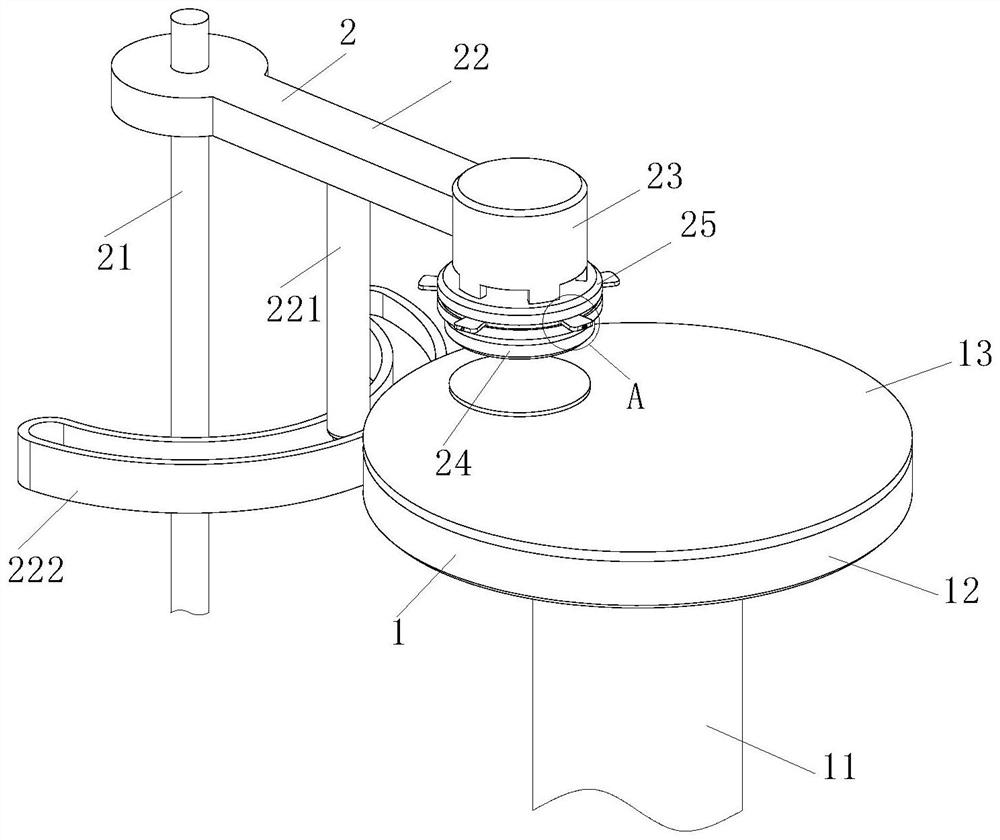

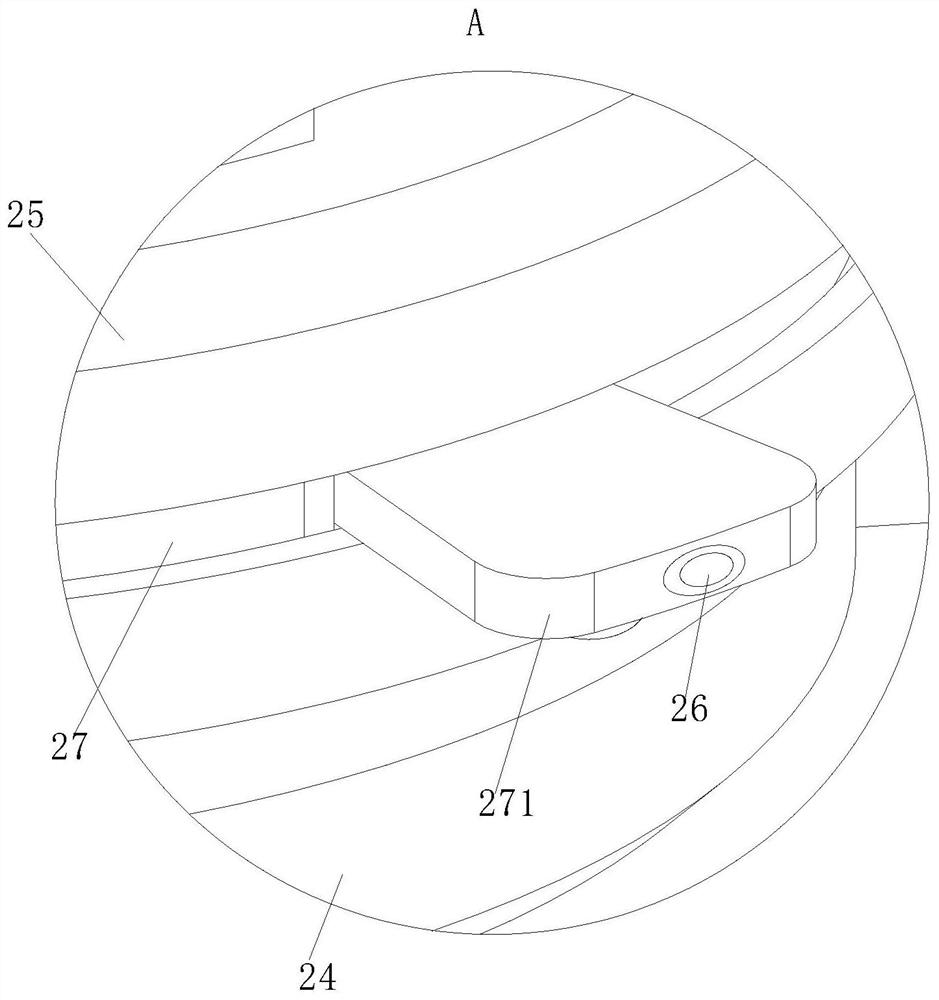

[0033] As a specific embodiment of the present invention, an annular groove 27 is opened on the outer ring side wall of the base plate 25, and a plurality of connecting plates 271 are arranged in the annular groove 27; the section surface of each connecting plate 271 is in the shape of the letter " T "shape, the vertical two ends of each connecting plate 271 are embedded in the annular groove 27, the distance sensor 26 is affixed on the horizontal end of each connecting plate 271, and the polishing pad that the emission end of distance sensor 26 points to the outside is used for adjusting device;

[0034]The chemical mechanical polishing equipment needs the adjusting arm of the polishing pad to swing back and forth during the grinding, and the grinding head 24 is also doing the swinging action at the same time. The grinding head 24 with the regulator is fixed on the base of the equipment by multiple screws, and after the chemical mechanical grinding equipment has been running ...

specific Embodiment approach

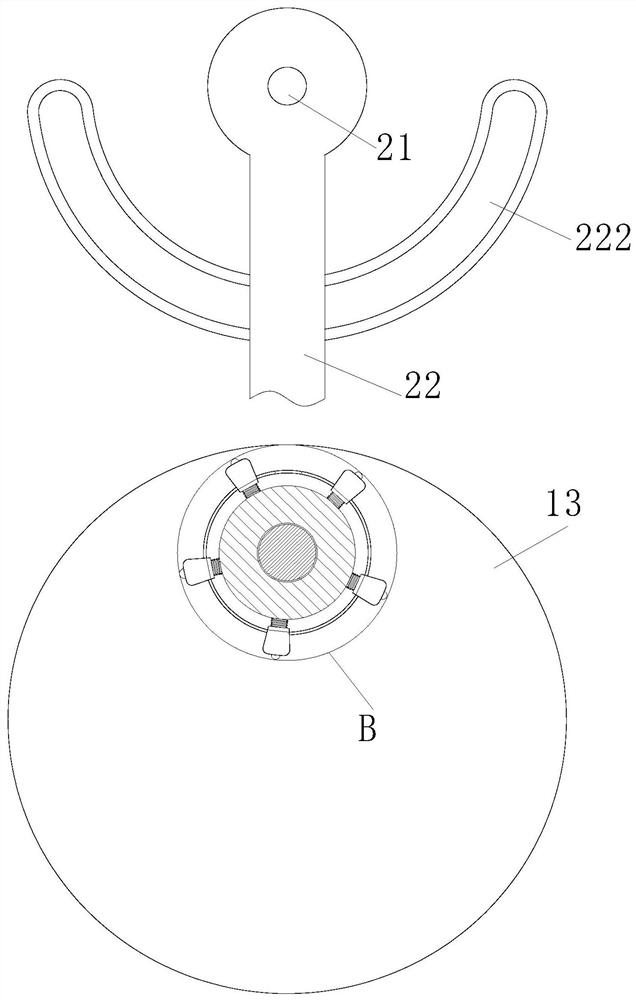

[0038] As a specific embodiment of the present invention, the other end of the support rod 221 is provided with a groove, and a ball 223 is arranged in the groove; the ball 223 is rollingly connected in the groove, and the ball 223 is rollingly connected in the slide rail 222 The swing of the crossbar 22 is supported by the support rod 221, the stability of the horizontal movement of the crossbar 22 is enhanced, and the quality of the motor 23 and the grinding head 24 is prevented from pressing down on the other end of the crossbar 22, causing the crossbar 22 to tilt, which affects the grinding The horizontal accuracy of the grinding end of the head 24, and the rolling connection of the ball 223 installed at the other end of the support rod 221 in the slide rail 222 reduces the friction between the support rod 221 and the slide rail 222, so that the support rod 221 supports the cross bar 22 stably Swing, reduce the impact on distance sensor 26 detection distance work.

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com