Matte black polyamide film for lithium ion battery and black master batches and preparation method thereof

A polyamide film and lithium-ion battery technology, applied in chemical instruments and methods, battery components, circuits, etc., to achieve the effects of enhancing capabilities, increasing output and production capacity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

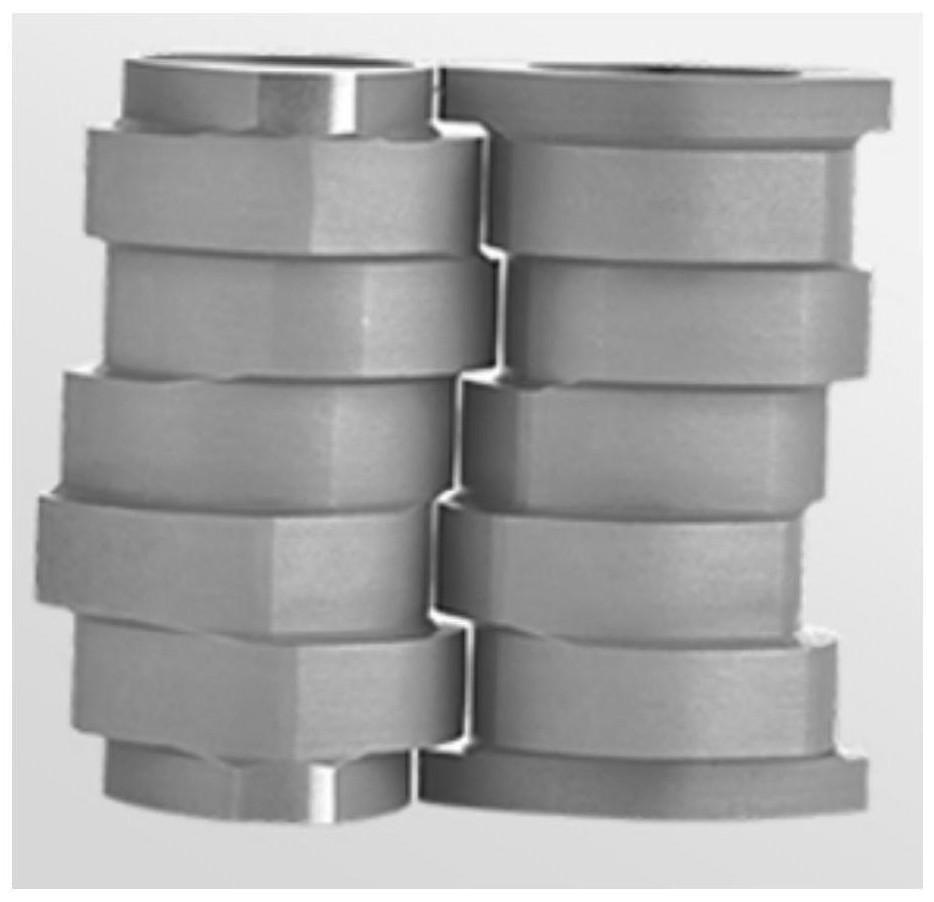

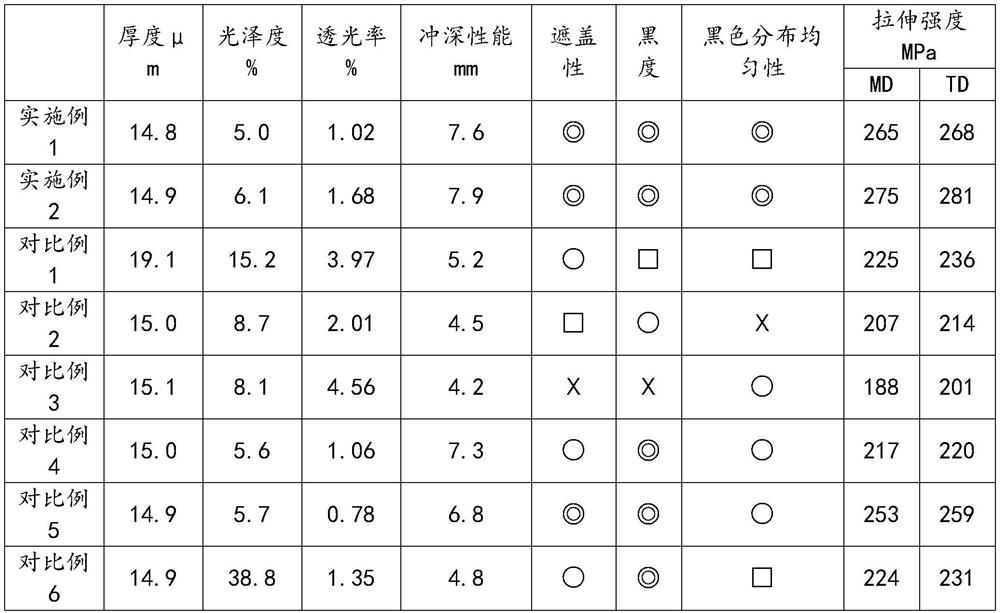

[0053] The matte black polyamide film for lithium-ion batteries in this embodiment comprises a three-layer film structure, which is a matte black polyamide upper surface layer, a polyamide middle layer and a black polyamide lower surface layer sequentially from top to bottom. In parts by mass, the upper surface layer includes 5 parts of black masterbatch, 10 parts of toughening agent, 5 parts of matting agent, 2 parts of additives, and 78 parts of polyamide; the middle layer is 100 parts of polyamide Amide; the lower surface layer includes 5 parts of black masterbatch, 10 parts of toughening agent, 2 parts of additives, and 83 parts of polyamide.

[0054] In this example, the additives are selected from lubricants, anti-blocking agents, and antioxidants in three mixtures in a ratio of 1:2:1, the lubricants are selected from erucamide; the antioxidants are selected from antioxidants 1098, anti-oxidants A mixture of three kinds of oxygen agent 168 and antioxidant SEED in a ratio...

Embodiment 2

[0074] The matte black polyamide film for lithium-ion batteries in this embodiment has a three-layer film structure, which is a matte black polyamide upper surface layer, a polyamide middle layer and a black polyamide lower surface layer from top to bottom. In parts by mass, the upper surface layer includes 3 parts of black masterbatch, 10 parts of toughening agent, 3 parts of matting agent, 2 parts of additives, and 82 parts of polyamide; the middle layer is 100 parts of polyamide Amide; the lower surface layer includes 3 parts of black masterbatch, 10 parts of toughening agent, 2 parts of additives, and 85 parts of polyamide.

[0075] In this example, the additives are selected from three mixtures of lubricant, anti-blocking agent and antioxidant in a ratio of 1:2:1; the lubricant is selected from erucamide; the antioxidant is selected from antioxidant 1098, anti-oxidant A mixture of three kinds of oxygen agent 168 and antioxidant SEED in a ratio of 2:1:2; the blocking agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com