Full-light concrete for concrete structure floor and preparation process thereof

A technology of all-light concrete and concrete structure, applied in the field of concrete building materials, can solve the problems of poor construction performance and low strength of all-light concrete, and achieve the effects of improving construction performance and mechanical performance, reducing floating situation and reducing self-weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

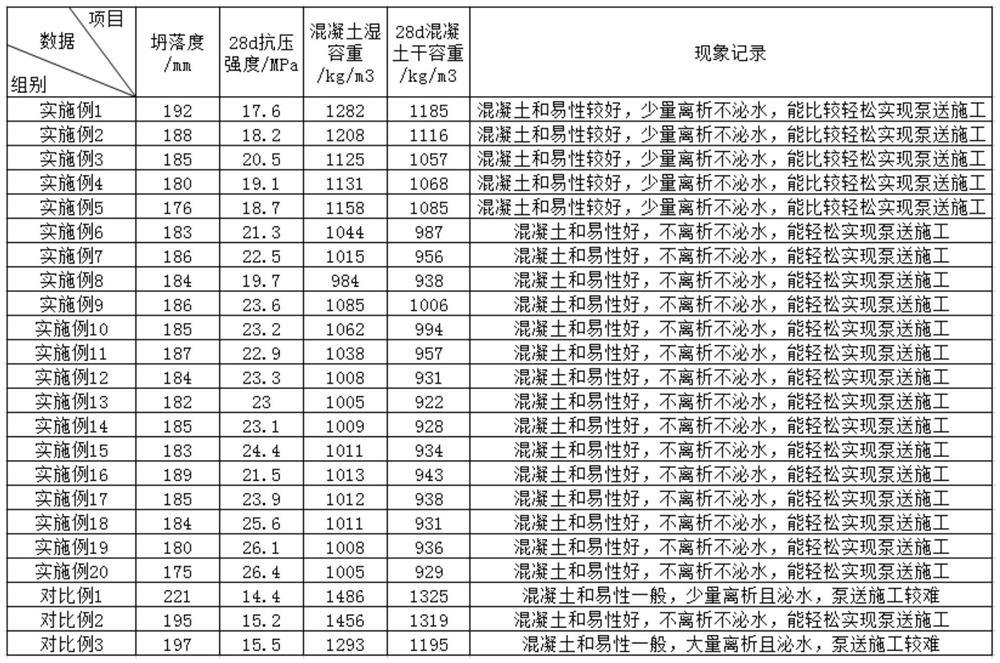

Examples

Embodiment 1

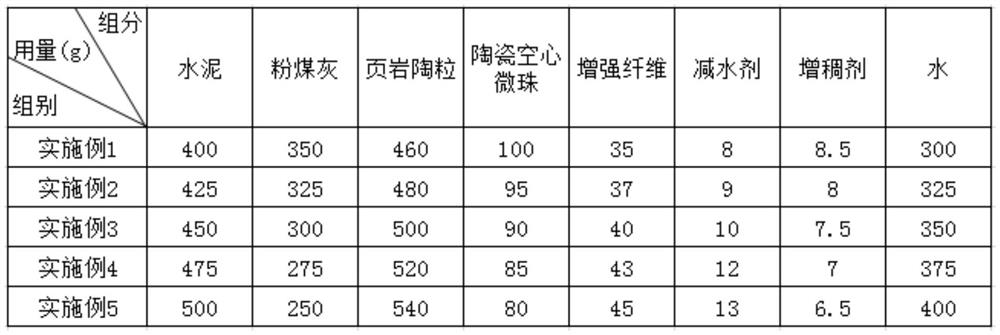

[0036] A kind of all-light concrete for concrete structure floor slab, its component content is shown in Table 1.

[0037] Table 1 embodiment 1-5 component content table

[0038]

[0039] Among them, the density of shale ceramsite is 364kg / m 3 , The porosity is 42% and the continuous gradation is 5-15mm.

[0040] The particle size of ceramic hollow microspheres is 0.4-0.8mm, and the bulk density is 153kg / m 3 , the wall thickness is between 0.05-0.1mm.

[0041] Steel fiber is selected as the reinforcing fiber, the length is 5-8mm, and the diameter is 0.2-0.3mm.

[0042] The water reducing agent is carboxylic acid water reducing agent.

[0043] The thickener is selected dextrin.

[0044] This embodiment also provides a method for preparing the above-mentioned full-light concrete for the concrete structure floor, including a cementitious material premixing process, a light aggregate premixing process, and a concrete mixing process;

[0045] Among them, premixing of cemen...

Embodiment 2

[0048] A kind of all-light concrete for concrete structure floor. The difference between this embodiment and Embodiment 1 is that its component content is shown in Table 1.

[0049] This embodiment also provides a preparation method of the above-mentioned full-light concrete for the concrete structure floor. The difference between this preparation method and Embodiment 1 is that the concrete mixing process is as follows: Concrete mixing: adding pre-mixed aggregates to the pre-mixed concrete In the glue material, stir while adding and keep stirring for 160s after adding, then continue to add water reducer and water, and stir for 130s to mix all-light concrete.

Embodiment 3

[0051] A kind of all-light concrete for concrete structure floor. The difference between this embodiment and Embodiment 1 is that its component content is shown in Table 1.

[0052] This embodiment also provides a preparation method of the above-mentioned full-light concrete for the concrete structure floor. The difference between this preparation method and Embodiment 1 is that the concrete mixing process is as follows: Concrete mixing: adding pre-mixed aggregates to the pre-mixed concrete In the rubber, stir while adding and keep stirring for 165s after the addition is complete, then continue to add water reducer and water, and stir for 135s to mix all-light concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com