A Real-time Control Device for Circular Weft Machine

A real-time control, circular weft machine technology, applied in the direction of computer control, general control system, program control, etc., can solve the problems of compatibility, unfavorable standardization and modular design, difficult to be universal, etc., to improve anti-interference. It is beneficial to standardization and modular design, and the effect of avoiding communication obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

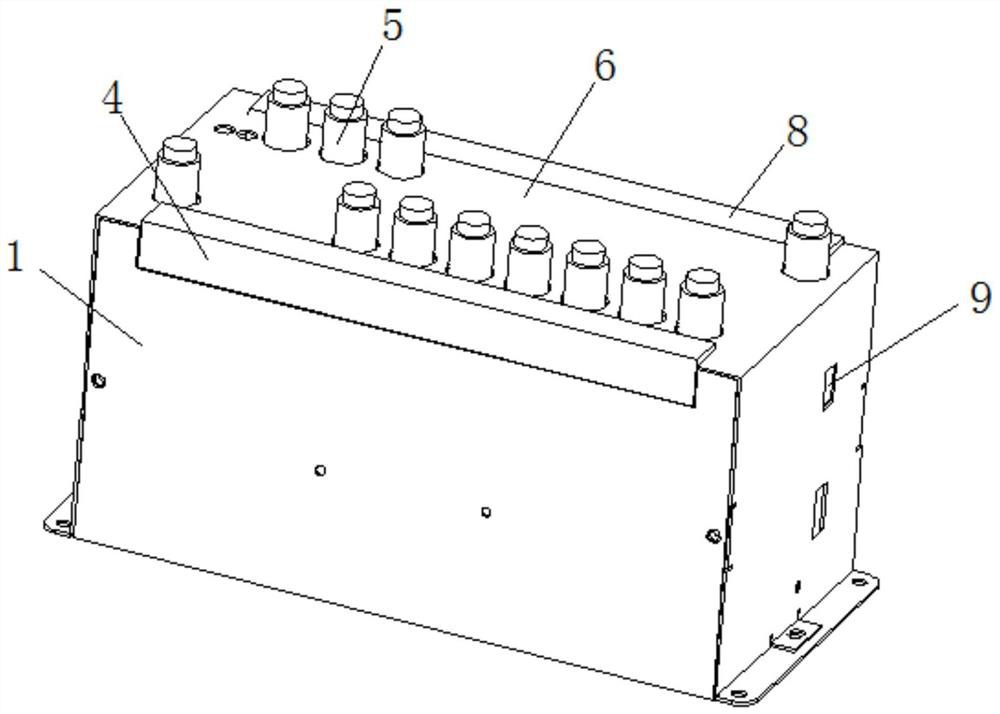

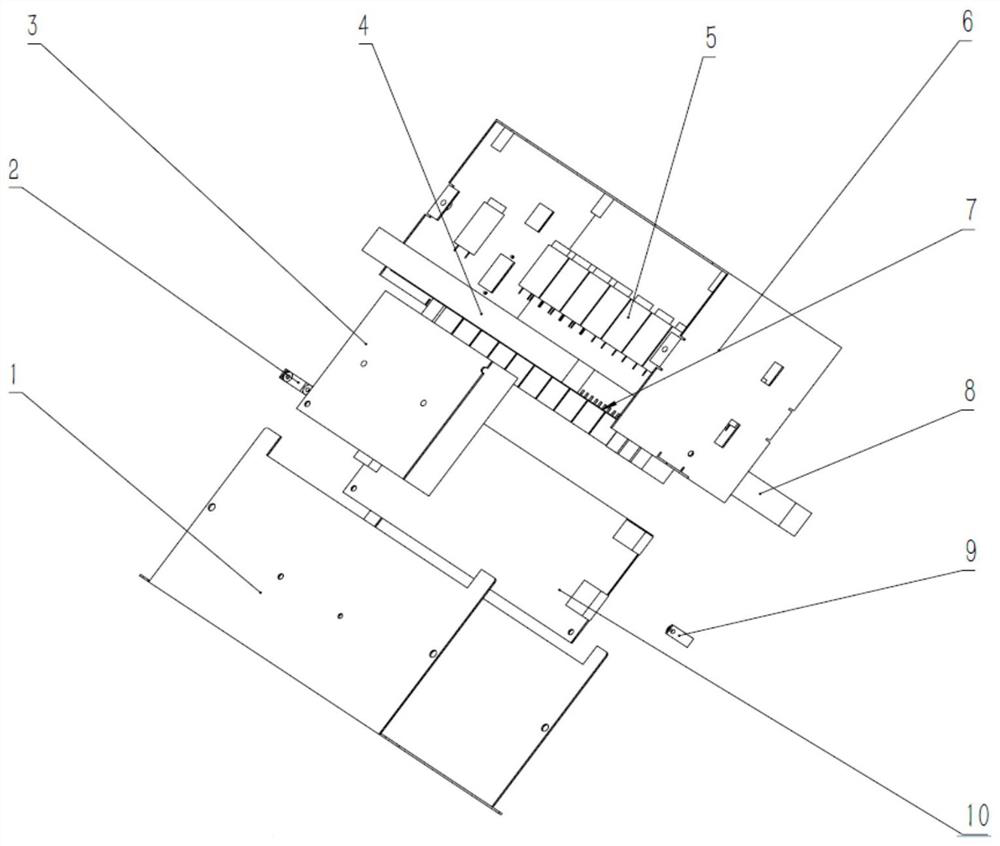

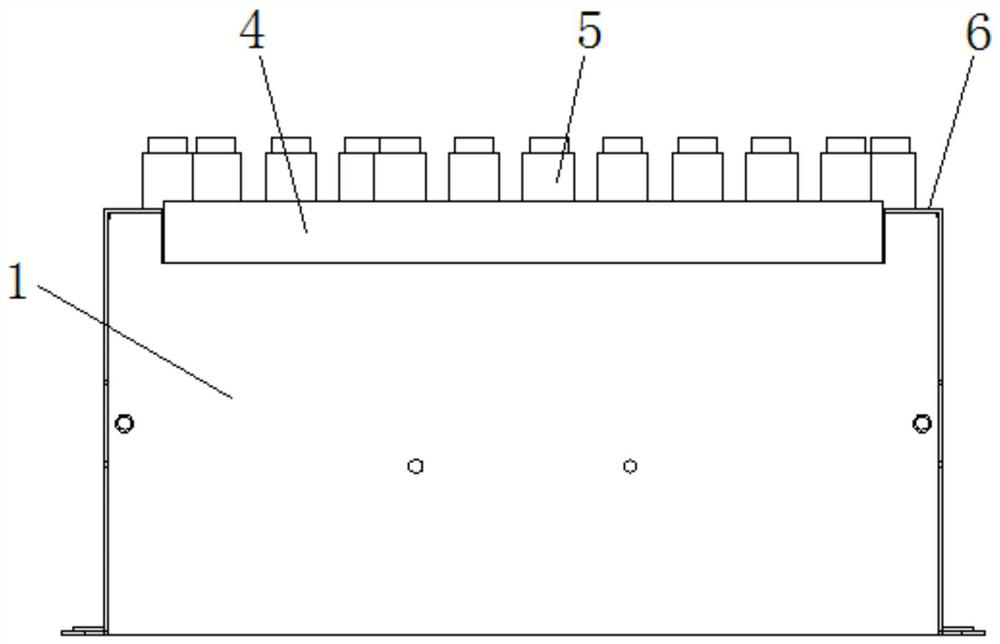

[0041] An embodiment of the present invention provides a real-time control device for a circular weft machine, such as Figure 1-15 As shown, it includes U-shaped sheet metal base plate 1, U-shaped sheet metal mounting panel 6, control circuit PCB board, 24V output switching power supply 3, and several L-shaped ear holders 2;

[0042] like Figure 1-10 As shown, the U-shaped sheet metal base plate 1 and the U-shaped sheet metal mounting panel 6 are arranged vertically and staggeredly, and are fastened by screws to form a rectangular shell, and the front and rear sides are closely fitted; Through holes, the control device can be fixed on the circular weft machine, and 24V output switching power supply 3 can be installed on the inner surface, and there are four through holes on each side, which can be fastened with the type sheet metal mounting panel 6; U-shaped sheet metal There are 12 large round through holes and two small round through holes on the bottom surface of the gol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com