High-adhesion textile size special for polyester cotton

A technology of textile size and high adhesion, applied in the direction of textiles and papermaking, wear-resistant fibers, fiber types, etc., can solve problems such as low viscosity, uneven sizing, poor wear resistance, etc., to reduce fluff and breakage chance, uniform sizing, and strong wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

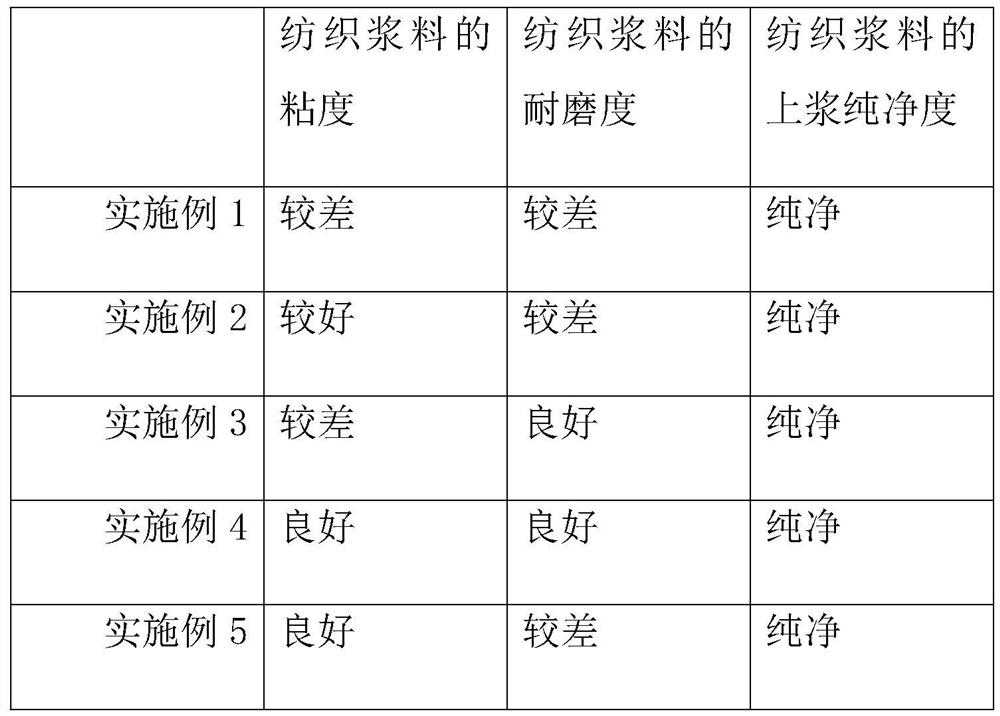

Examples

Embodiment 1

[0040]Example 1, a high-adhesion polyester-cotton special textile slurry provided by the present invention includes a mixture, a compound and a filler. The mixture includes polyacrylate, epoxy resin, starch and water. Compounding agents include alkali reducing agents, softening agents, anti-aging agents and anti-cracking agents, and the fillers include graphene, silica powder, and glass fiber;

[0041]The mixture (in parts by weight) is respectively: 30 parts of polyacrylate, 10 parts of epoxy resin, 5 parts of starch, and 30 parts of water;

[0042]The compounding agents (in parts by weight) are: 2 parts of alkali reducing agent, 6 parts of softening agent, 6 parts of anti-aging agent, and 6 parts of anti-cracking agent;

[0043]The fillers (in parts by weight) are respectively: 10 parts of graphene, 6 parts of silica powder, and 6 parts of glass fiber.

[0044]It also includes a processing method, specifically the following preparation steps:

[0045]S1: Stirring by putting quantitative graphene...

Embodiment 2

[0062]Embodiment 2, the present invention provides a high-adhesive polyester-cotton special textile sizing agent, which includes a mixture, a compound and a filler. The mixture includes polyacrylate, epoxy resin, starch and water. Compounding agents include alkali reducing agents, softening agents, anti-aging agents and anti-cracking agents, and the fillers include graphene, silica powder, and glass fiber;

[0063]The mixture (in parts by weight) is respectively: 35 parts of polyacrylate, 15 parts of epoxy resin, 10 parts of starch, and 35 parts of water;

[0064]The compound (in parts by weight) is respectively: 3 parts of alkali reducing agent, 7 parts of softening agent, 7 parts of anti-aging agent, 7 parts of anti-cracking agent;

[0065]The fillers (in parts by weight) are respectively: 15 parts of graphene, 7 parts of silica powder, and 7 parts of glass fiber.

[0066]It also includes a processing method, specifically the following preparation steps:

[0067]S1: Stirring by putting quantitat...

Embodiment 3

[0084]Embodiment 3, a high-adhesive polyester-cotton special textile slurry provided by the present invention includes a mixture, a compound, and a filler. The mixture includes polyacrylate, epoxy resin, starch, and water. Compounding agents include alkali reducing agents, softening agents, anti-aging agents and anti-cracking agents, and the fillers include graphene, silica powder, and glass fiber;

[0085]The mixture (in parts by weight) is: 40 parts of polyacrylate, 20 parts of epoxy resin, 15 parts of starch, and 40 parts of water;

[0086]The compound (in parts by weight) is: 4 parts of alkali reducing agent, 8 parts of softening agent, 8 parts of anti-aging agent, and 8 parts of anti-cracking agent;

[0087]The fillers (in parts by weight) are respectively: 20 parts of graphene, 8 parts of silica powder, and 8 parts of glass fiber.

[0088]It also includes a processing method, specifically the following preparation steps:

[0089]S1: Stirring by putting quantitative graphene, silica powder an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com