Shock absorber damping control and performance evaluation method, shock absorber optimized through method and vehicle comprising shock absorber

A damping control and shock absorber technology, used in shock absorbers, liquid shock absorbers, shock absorbers, etc., can solve the problem that there is no clear standard for the corresponding relationship between the stroke position and the damping force value, and achieve easy selection and matching. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

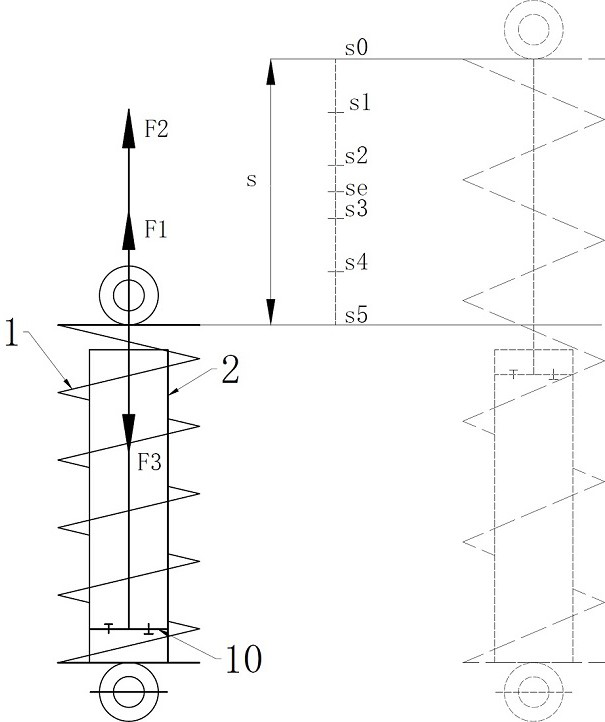

[0101] Preferred option 1: a method for judging the performance of a shock absorber (such as figure 1 , figure 2 shown)

[0102] The force value F1 of the shock absorber is marked as F1' when it is the tensile damping force value, and it is marked as F1" when the force value F1 of the shock absorber is the compressive damping force value.

[0103] When the supporting force value of the supporting spring is F2, and the weight value of the vehicle body supported by the supporting spring and the shock absorber is F3, then the tensile damping force value F1' of the shock absorber and the compressive resistance value F1" of the shock absorber are closer When F2 is subtracted from F3, the performance of the shock absorber is better.

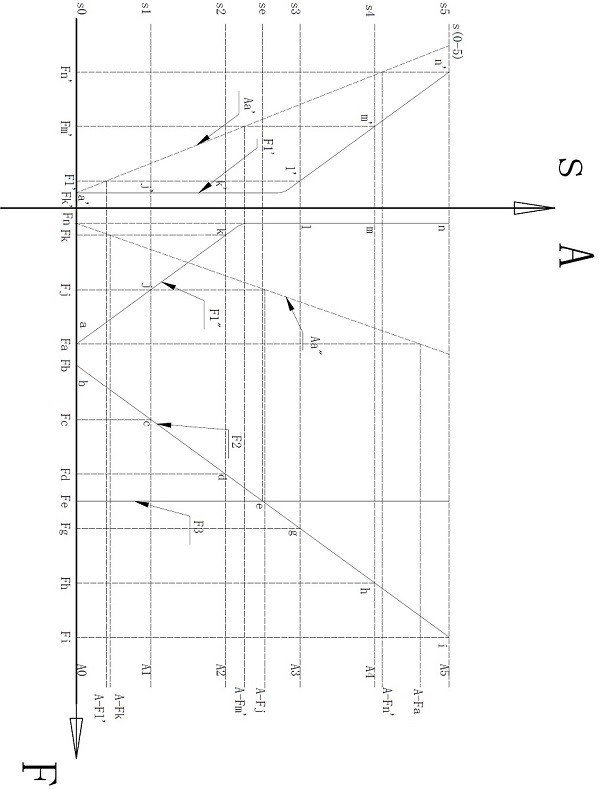

[0104] The relationship between the damping force value of the shock absorber and the stroke position (as shown in Figure 2):

[0105] In the figure, the shock absorbers s0~s5 are the specific stroke position points, F1' is the curve corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com