Rapid pretreatment method for measuring carbon isotopes in water and sampling device

A carbon isotope, rapid technology, applied in the preparation of test samples, etc., can solve the problem of time-consuming and other problems, and achieve the effect of less material, convenient operation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] According to the rapid pretreatment method for measuring carbon isotopes in water described in the application, it may further comprise the steps:

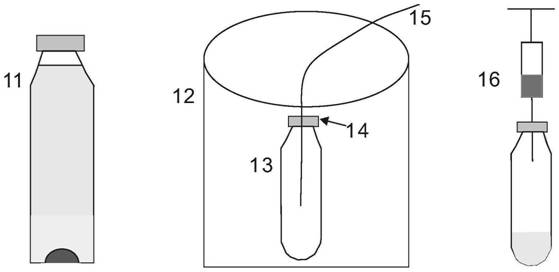

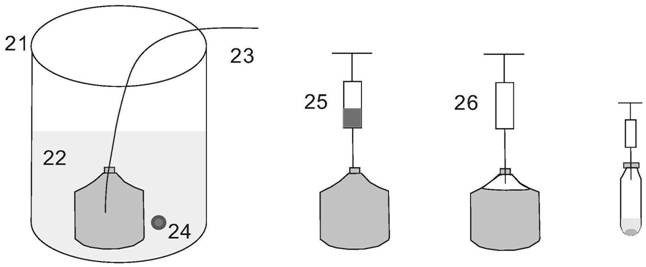

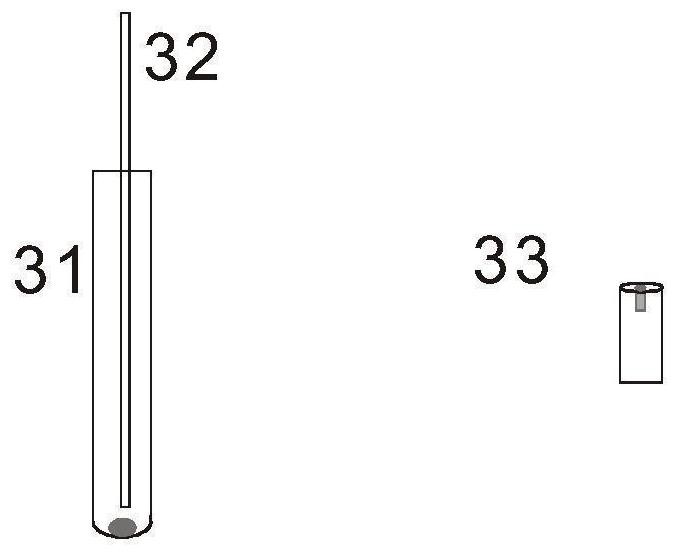

[0060] (1) Preparation of Ba(OH) 2 Saturated solution: add 80mL deionized water to 100mL glass bottle 11, then add 5g Ba(OH) 2 ·8H 2 O, making saturated Ba(OH) 2 Solution, for subsequent use; choose the round-bottomed glass bottle 13 with a volume of 5mL as a reaction bottle, put it in a flushing bag 12 full of argon with a volume of 5L, put the argon gas guide tube 15 into the round-bottomed glass bottle 13, and use Rinse the inside of the bottle with argon gas 3 times, seal it with a screw cap 14 with a silica gel septum, then evacuate the round bottom glass bottle 13 to below 200Pa, then use the first syringe 16 of 5mL specification (cleaned 3 times with argon gas before use) ) absorb the saturated Ba(OH) in the glass bottle 11 2 2 mL of the solution was poured into the round bottom glass bottle 13.

[0061] (2) Put...

Embodiment 2

[0065] About BaCO 3 Screening of the mass ratio of solid powder to Ta powder:

[0066] Prepare BaCO by the method of embodiment 1 3 solid powder. Take BaCO 3 Solid powder and 325 mesh Ta powder (purity is 99.9%), divide into 4 parts respectively, BaCO 3 Put the solid powder and Ta powder into the glass test tube according to the mass ratio of 1:0.5, 1:1, 1:2, 1:3 respectively, mix evenly with a glass rod, and then add the evenly mixed powder to the center hole of the copper target In the process of crushing and compacting, the pretreatment is completed. On the accelerator mass spectrometer of 5MV, the cesium ion beam bombards the mixed powder in the center hole of the copper target, so that the powder in the powder 12 C is charged to become 12 C 3+ , it was found experimentally that BaCO 3 When the mass ratio of solid powder and Ta powder is 1:(1~2) 12 C 3+ The highest current value generated (see Figure 4 ), that is, Ta has the highest efficiency in the measurement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com