Gas relay for detecting transformer faults in real time, and diagnosis method thereof

A gas relay and transformer failure technology, applied to transformer/inductance parts, instruments, circuits, etc., can solve the problems of untimely gas detection, transformer damage, poor effectiveness, etc., and achieve rapid detection, accurate diagnosis, and strong effectiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0067] The first embodiment: a gas relay for real-time detection of transformer faults

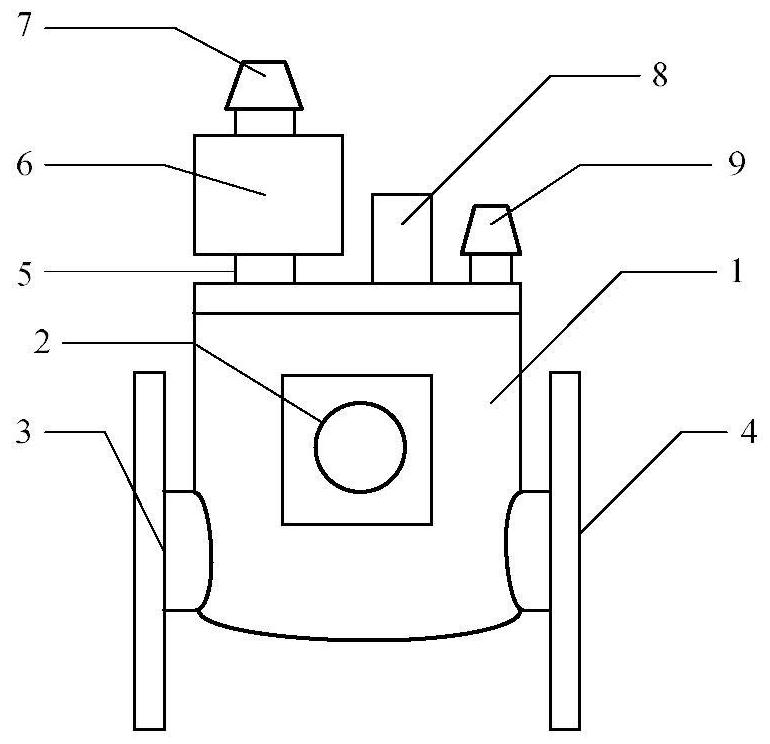

[0068] Such as figure 1 As shown, the present invention provides a gas relay for real-time detection of transformer faults, comprising: a gas relay body 1, an observation window 2, an oil inlet 3, an oil outlet 4, a first air pipe 5, a bottle to be inspected 6, and a gas relay Deflation plug 7, collection and transmission unit 8 and probe 9.

[0069] The bottle 6 to be inspected is a transparent container, which is used to collect the gas released inside the gas relay body 1. One end of the bottle 6 to be inspected is connected to the gas relay body 1 through the first air pipe 5, and the other end is connected to the air release plug of the gas relay through the second air pipe. 7 phase connections.

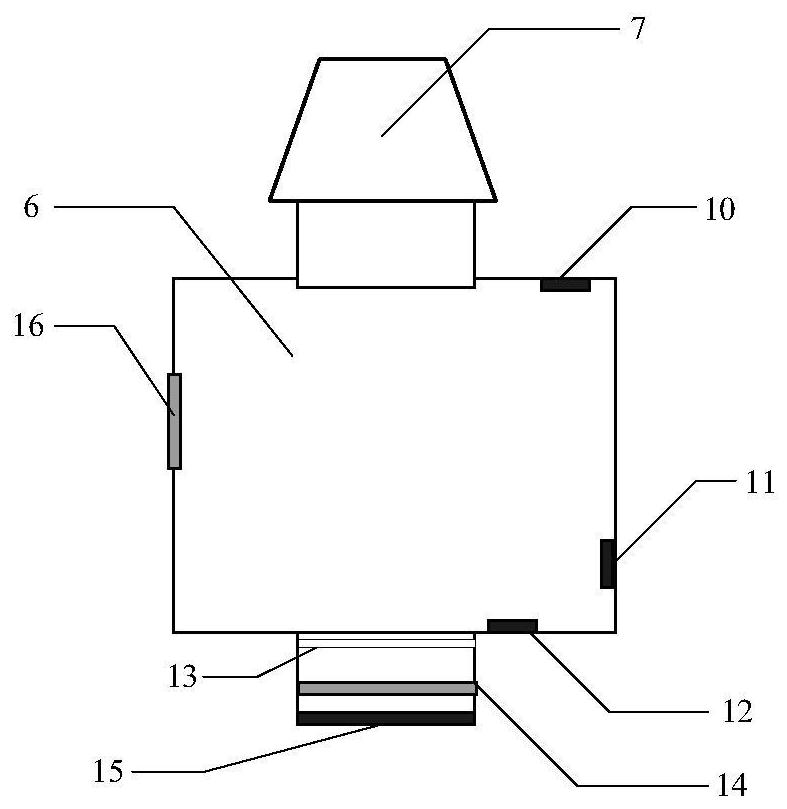

[0070] Such as figure 2 As shown, a faulty gas detection module connected to the collection and sending unit 8 is set in the bottle 6 to be inspected to detect whether the bottle 6 to be...

no. 2 example

[0091] Second embodiment: a diagnostic method for real-time detection of transformer faults

[0092] Such as Figure 4 As shown, the second embodiment of the present invention provides a diagnostic method using the above gas relay for real-time detection of transformer faults, comprising the following steps:

[0093] Step 1, gas accumulation occurs inside the transformer. If the pressure sensor 15 detects that the gas pressure inside the gas relay body 1 reaches the threshold K1, the air intake solenoid valve 14 is controlled to open, and the gas inside the gas relay body 1 passes through the intake solenoid valve 14 and the filter. The oil net 13 enters the bottle 6 to be inspected; after that, if the pressure sensor 15 detects that the gas pressure inside the gas relay body 1 drops below the threshold K1, the intake solenoid valve 14 is controlled to close.

[0094] Step 2, the hydrocarbon detection sensor 10 arranged inside the bottle 6 to be inspected detects whether the ...

example 1

[0124] Example 1, the accumulation of gas in a transformer gas relay caused the gas relay to send out an alarm signal, and the site could not immediately judge whether it was gas or air caused by the internal fault of the transformer. Utilizing the technology of the invention, the hydrocarbon sensor detects hydrocarbon gas at 16.5ppm, and the characteristic value of Pq is 2. The electronic nose sensor detects the irritating odor, and the characteristic value of Pd is 2. The gas color detected by the color change sensor is yellow, and the characteristic value of Ps is 2. Through the comprehensive detection and diagnosis, the P is 17.8. It is judged that there is a critical fault inside the transformer, and timely prompts the substation operators to stop the power for emergency treatment. After a timely power outage and inspection, it was found that there were serious discharge traces inside the transformer. Through timely power outage and effective measures, further damage to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com