Optical fiber end face pumping coupler preparation method based on casing pipe method

An optical fiber end face and sleeve method, which is used in the coupling of optical waveguides, lasers, laser components, etc., can solve the problems of mode degradation and increased transmission loss, and achieve high power, system performance improvement, and high beam quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

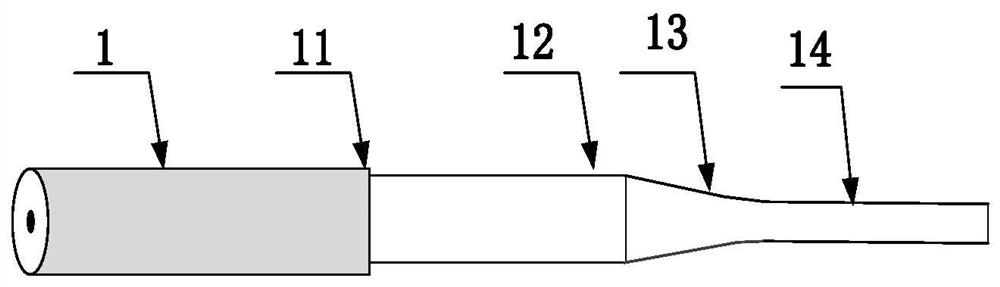

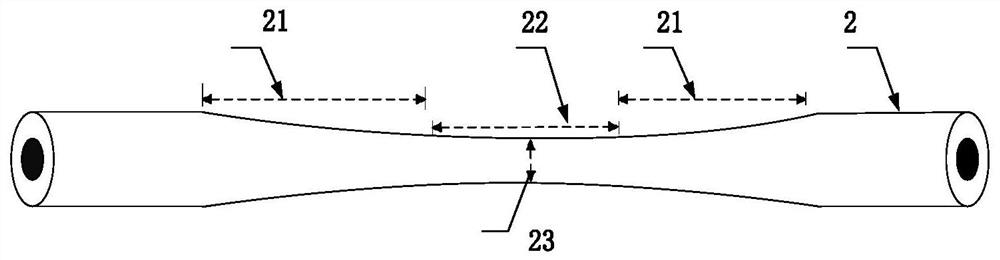

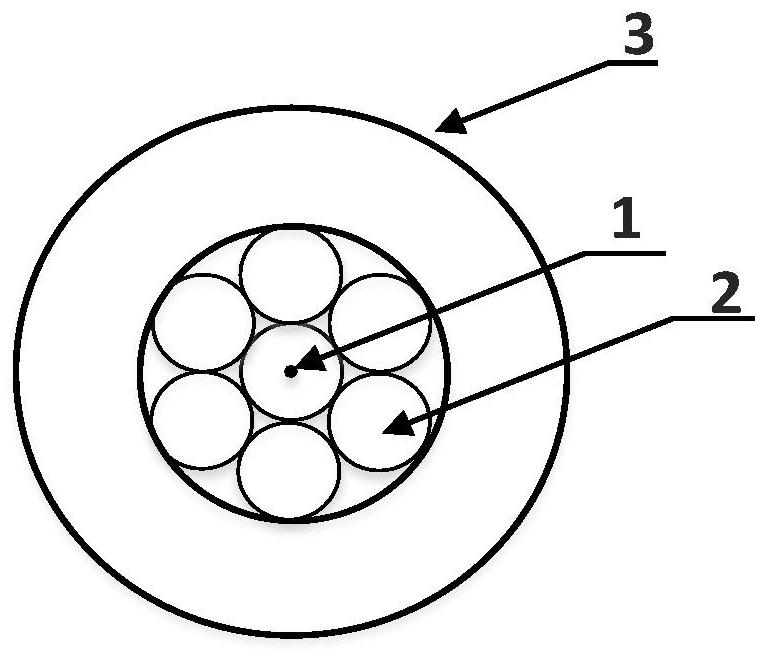

[0023] The invention provides a method for preparing an optical fiber end-face pumping coupler based on a casing method, which is a method for manufacturing an optical fiber end-face coupler containing signal fibers based on (N+1)×1 arbitrary output fiber size. In this embodiment, the inner diameter / outer diameter is 20 / 400 μm (NA=0.06 / 0.46) double-clad fiber and 6 double-clad fibers whose structural parameters are 220 / 242 μm (NA=0.22) as examples, using the present invention The provided method for preparing an optical fiber end-face pump coupler based on the bushing method is used to describe the manufacture of a (6+1)×1 pump coupler. The specific steps are as follows:

[0024] 1) Fabricate the input signal fiber.

[0025] figure 1 It is the structure schematic diagram of the input signal fiber after corrosion in embodiment 1; Mainly comprise input signal fiber 1, input signal fiber 1 adopts 20 / 400 μm (NA=0.06 / 0.46) double-clad fiber, wherein 11 is 20 / 400 μm (NA= 0.06 / 0.46...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com