Hydrogen sulfide removal process by use of a sulfur dye catalyst

A catalyst, hydrogen sulfide technology, used in catalyst regeneration/reactivation, physical/chemical process catalysts, sulfur compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

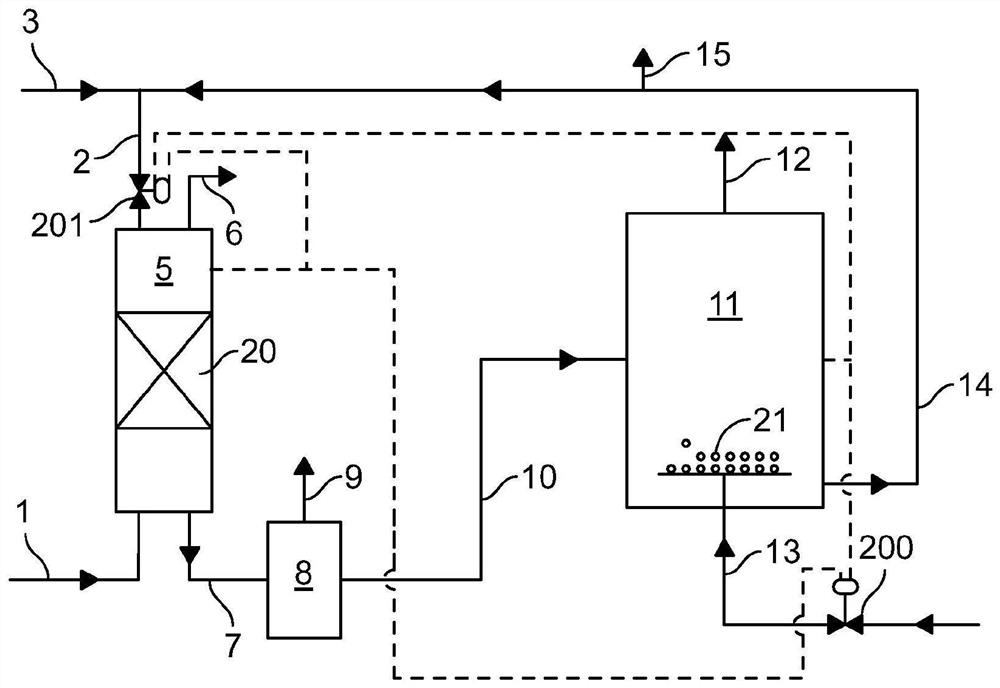

[0053] The following is based on figure 1 The description only presents one possible treatment method to achieve the object of the present invention, namely the removal of H from industrial fluid streams 2 S and produce useful thiosulfate products.

[0054] figure 1 A continuous process using absorber vessel 5 and oxidation reactor 11 operating in series is shown. Feed stream 1 (e.g., from 2 A feed consisting of natural gas of S) is fed to the bottom of the absorber 5 at a pressure of 30 bar gauge and directed in an upward flow for countercurrent contact with the liquid treatment solution 2 introduced at the top of the absorber 5 . Alternatively, the feed may be free of hydrocarbon components, for example, the feed may contain hydrogen sulfide and non-hydrogen gases. Such non-hydrogen gases can be air recovered from amine systems or CO recovered from sour water stripping processes 2 .

[0055] The absorber may contain solid media or may be a bubble column. Other feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com