Method of preparing a microcrystalline cellulose reinforced polymer composite

A technology of microcrystalline cellulose and polymers, which is applied in the field of preparing microcrystalline cellulose-reinforced polymer composites, and can solve problems such as inability to solve degradation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Example 1: Preparation of jMCC masterbatch by jet milling process

[0077] Microcrystalline cellulose (MCC) purchased from FMC Biochemical was subjected to jet milling in order to reduce the size of the cellulose (jMCC) and in order to improve the dispersibility of the cellulose in the polypropylene solution. Using the provided by Sturtevant Dry milling of MCC was performed by jet milling (Jetmill) operating at a feed rate of 300 grams per hour to obtain finer particles. To determine the milled particle size, particle size analysis was performed using a laser diffraction particle size analyzer.

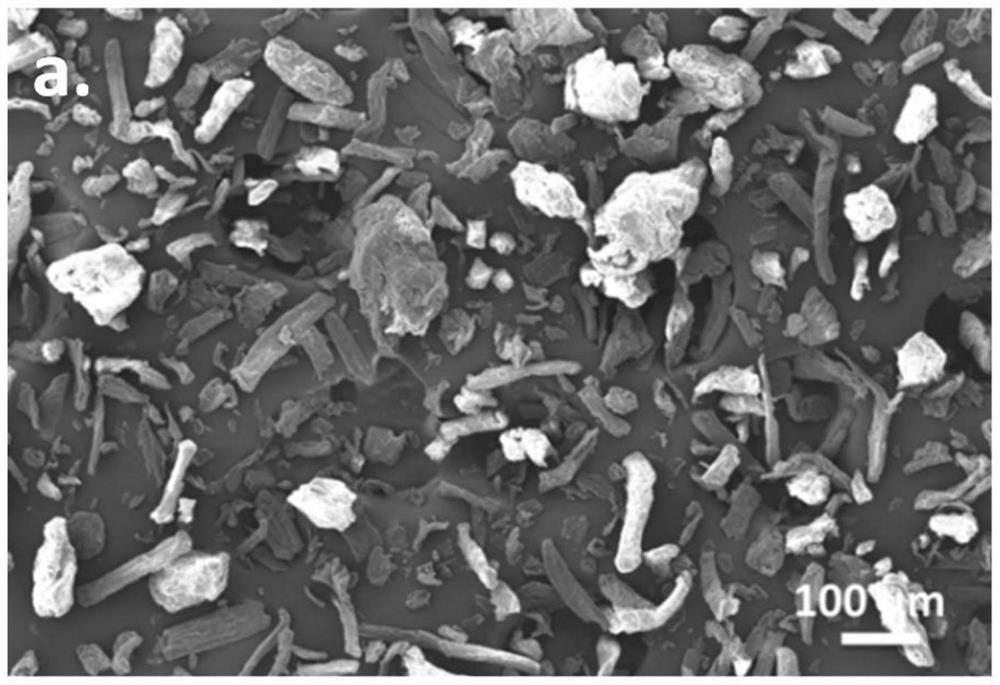

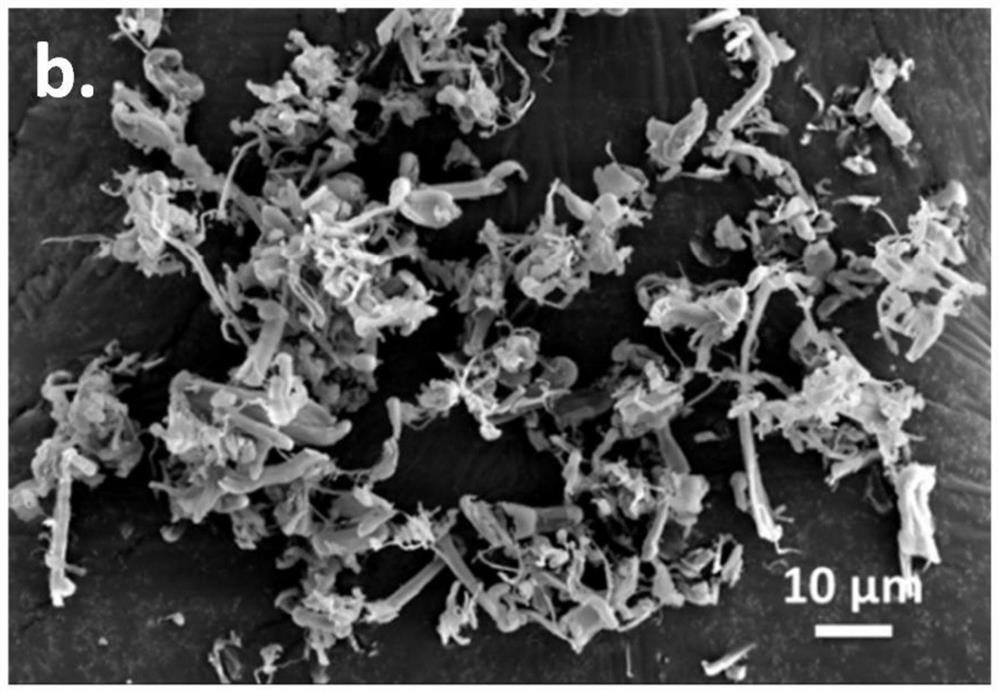

[0078] The structure of the starting material, as well as the morphology of the MCC and the MCC after pretreatment (e.g. jet milling) in Figure 1A with Figure 1B shown in . As summarized in Table 1, commercially available MCC from FMC biopolymers has an average particle size of 140 μm, then as characterized by a particle size analyzer and as seen in SEM images, the commer...

Embodiment 2

[0082] Example 2: Preparation of PP / jMCC masterbatch by solution mixing process

[0083] This example shows the preparation of a non-functionalized jMCC masterbatch by a solution mixing process in which a thermoplastic polymer is used as the vehicle in a clay to polymer weight ratio of 1:2.

[0084] Disperse the jet-milled MCCs in an organic solvent suitable for polyolefin polymers. Afterwards, the jMCC was sonicated and homogenized to obtain a good dispersion. jMCC and PP were mixed, precipitated and dried to produce jMCC / PP masterbatch powder.

[0085] To prepare the masterbatch compound, xylene was used as solvent. Disperse jMCC in xylene at a concentration of 0.1 g / mL by stirring, homogenizing, and sonicating for 20 min, respectively, and repeating twice. PP was dissolved in xylene at a concentration of filler to polymer ratio of 1:10 w / v at 120 °C by stirring until the polymer was dissolved. Aliquots of jMCC dispersion and PP polymer solution were combined in a flas...

Embodiment 3

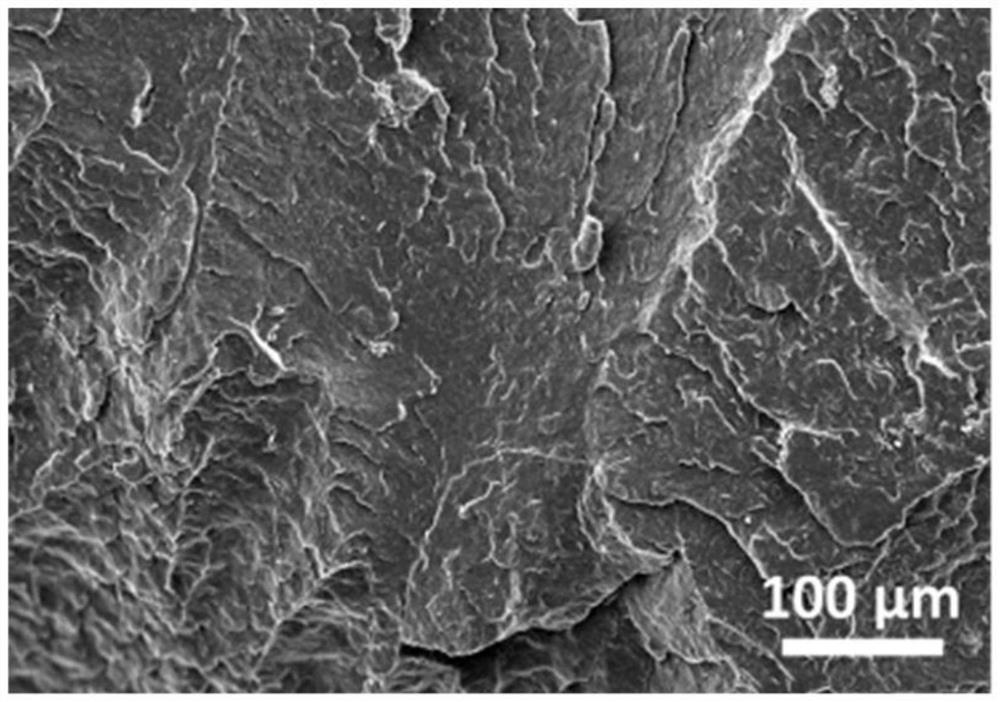

[0086] Example 3: Preparation of highly dispersed cellulose / polypropylene nanocomposites

[0087] The effect of MCC and jMCC (ie from masterbatches) on the mechanical properties of nanocomposite materials prepared by a melt blending process using a twin-screw extruder was investigated. In addition, the dispersion of fillers in the polymer matrix is used to understand the reinforcement mechanism of composite materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com