Modified ultrafiltration membrane capable of jointly inhibiting membrane biological pollution as well as preparation method and application thereof

A technology of combined suppression and ultrafiltration membrane, applied in the field of composite ultrafiltration membrane, can solve the problem of not reducing water flux, and achieve the effect of improving water flux, maintaining modification effect, and stabilizing modification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

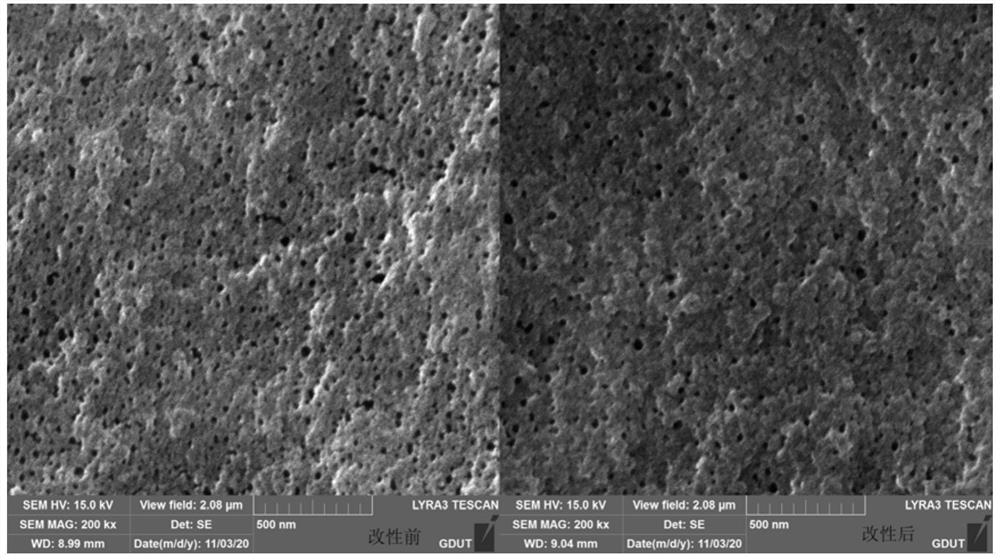

Image

Examples

Embodiment 1

[0041] A preparation method of a tannic acid-copper combined inhibition membrane biofouling modified ultrafiltration membrane, specifically comprising the following steps:

[0042] S1. Take out a clean blank PVDF ultrafiltration membrane (9cm in diameter), immerse it in a 500mL beaker filled with distilled water, soak for 30min, and fix the soaked blank PVDF ultrafiltration membrane on a custom modified container to make it The modified side (smooth side) faces up;

[0043]S2. take by weighing 170.12mg tannic acid and dissolve in 10mL deionized water, take by weighing 6.25mg pentahydrate·copper sulfate and dissolve in 10mL deionized water, tannic acid solution and copper sulfate solution are poured in the modification container successively, every When pouring a solution, it needs to be shaken for 30 seconds to make the modifier mix evenly;

[0044] S3. Wrap the modified container completely with aluminum paper to keep it in a dark state, fix the modified container on a water...

Embodiment 2

[0047] A method for preparing a modified ultrafiltration membrane combined with inhibiting membrane biofouling, specifically comprising the following steps:

[0048] S1. Take out a clean blank PVDF ultrafiltration membrane (9cm in diameter), immerse it in a 500mL beaker filled with distilled water, soak for 30min, and fix the soaked blank PVDF ultrafiltration membrane on a custom modified container to make it The modified side (smooth side) faces up;

[0049] S2. take by weighing 170.12mg tannic acid and dissolve in 10mL deionized water, take by weighing 12.50mg pentahydrate·copper sulfate and dissolve in 10mL deionized water, pour tannic acid solution and copper sulfate solution in the modified container successively, every When pouring a solution, it needs to be shaken for 30 seconds to make the modifier mix evenly;

[0050] S3. Wrap the modified container completely with aluminum paper to keep it in a dark state, fix the modified container on a water bath oscillator, and m...

Embodiment 3

[0053] A method for preparing a modified ultrafiltration membrane combined with inhibiting membrane biofouling, specifically comprising the following steps:

[0054] S1. Take out a clean blank PVDF ultrafiltration membrane (9cm in diameter), immerse it in a 500mL beaker filled with distilled water, soak for 30min, and fix the soaked blank PVDF ultrafiltration membrane on a custom modified container to make it The modified side (smooth side) faces up;

[0055] S2. take by weighing 170.12mg tannic acid and dissolve in 10mL deionized water, take by weighing 25.00mg pentahydrate·copper sulfate and dissolve in 10mL deionized water, pour tannic acid solution and copper sulfate solution in the modification container successively, every When pouring a solution, it needs to be shaken for 30 seconds to make the modifier mix evenly;

[0056] S3. Wrap the modified container completely with aluminum paper to keep it in a dark state, fix the modified container on a water bath oscillator, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com