Nickel-titanium alloy stent prepared based on metal additive manufacturing technology and preparation method thereof

A nickel-titanium alloy, manufacturing technology, applied in the field of nickel-titanium alloy stents and its preparation, can solve the problems of high phase transition temperature, cumbersome process, performance deviation of nickel-titanium alloy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

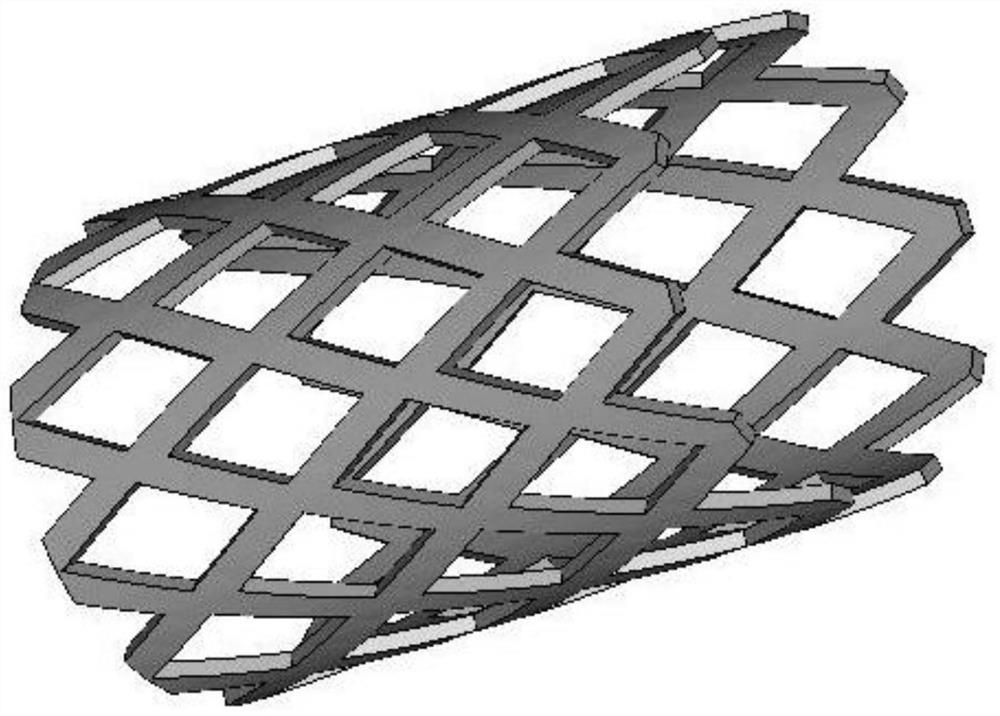

[0060] A method for preparing a nickel-titanium alloy rhombic network stent based on metal additive manufacturing technology, comprising the following steps:

[0061] (1) Detect the structure of the patient's affected part according to the CT scan, obtain the three-dimensional data of the affected part structure, design the size and shape of the stent according to the three-dimensional data of the affected part structure, and obtain a simulated stent; the simulated stent is 80 mm long, 10 mm in diameter, and 90 μm in wall thickness;

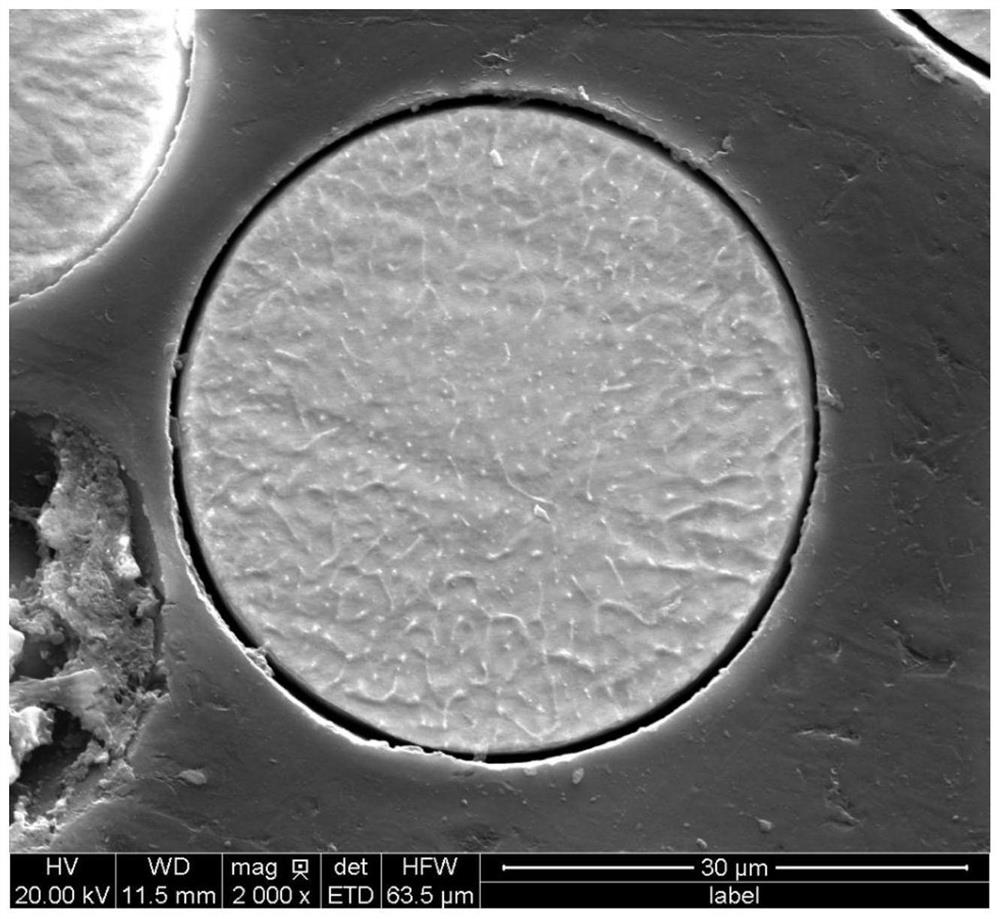

[0062] (2) using computer software to slice the simulated support obtained in the step (1) to form material units, the thickness of each layer of material unit is 30 μm, to obtain a multi-layer simulated support model;

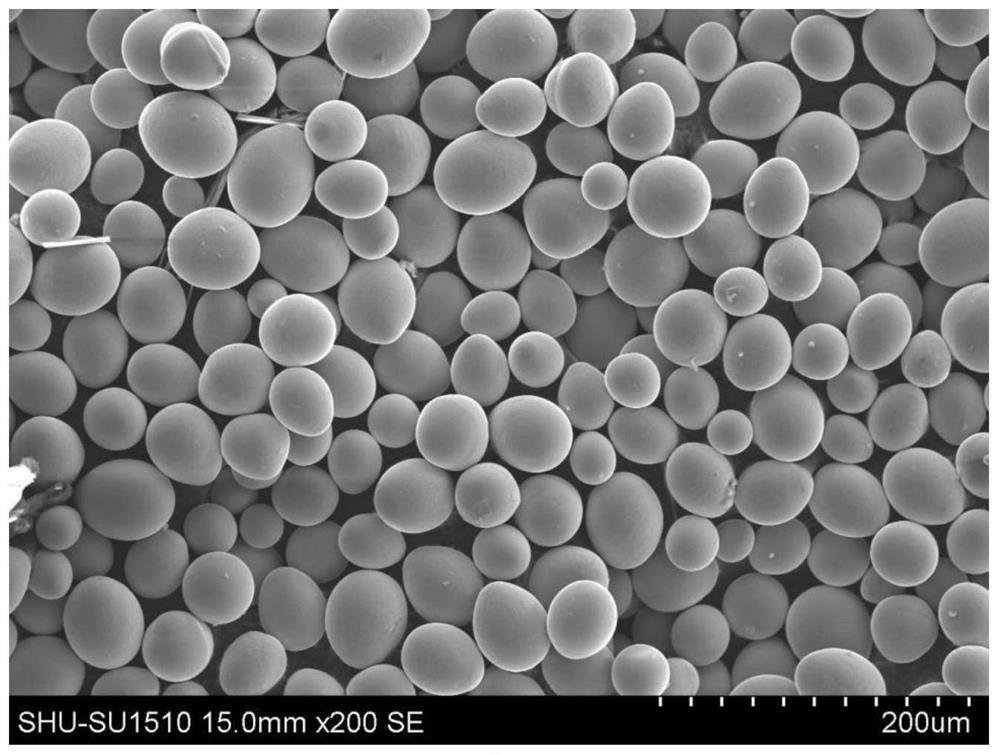

[0063] (3) Carry out 3D printing to the nickel-titanium alloy powder according to the multi-layer simulated bracket model in the step (2), to obtain the nickel-titanium alloy bracket; the content of Ni in the nickel-titanium alloy...

Embodiment 2

[0074] A method for preparing a nickel-titanium alloy S-shaped network stent based on metal additive manufacturing technology, comprising the following steps:

[0075] (1) Detect the structure of the affected part of the patient according to the CT scan, obtain the three-dimensional data of the affected part structure, design the size and shape of the stent according to the three-dimensional data of the affected part structure, and obtain a simulated stent; the simulated stent is 90 mm long, 12 mm in diameter, and 90 μm in wall thickness;

[0076] (2) using computer software to slice the simulated support obtained in the step (1) to form material units, the thickness of each layer of material unit is 30 μm, to obtain a multi-layer simulated support model;

[0077] (3) Carry out 3D printing to the nickel-titanium alloy powder according to the multi-layer simulation bracket model in the step (2), to obtain the nickel-titanium alloy bracket; the content of Ni in the nickel-titaniu...

Embodiment 3

[0086]A method for preparing a nickel-titanium alloy rhombic network vascular stent based on metal additive manufacturing technology, comprising the following steps:

[0087] (1) Detect the structure of the patient's affected part according to the CT scan, obtain the three-dimensional data of the affected part structure, design the size and shape of the stent according to the three-dimensional data of the affected part structure, and obtain a simulated stent; the simulated stent is 29 mm long, 3.5 mm in diameter, and 60 μm in wall thickness;

[0088] (2) using computer software to slice the simulated support obtained in the step (1) to form material units, the thickness of each layer of material unit is 30 μm, to obtain a multi-layer simulated support model;

[0089] (3) Carry out 3D printing to the nickel-titanium alloy powder according to the multi-layer simulated bracket model in the step (2), to obtain the nickel-titanium alloy bracket; the content of Ni in the nickel-titan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com