Method for removing zirconium from zirconium-doped ternary precursor waste dissolving solution

A precursor and solution technology, applied in the field of zirconium-doped ternary precursor waste solution for zirconium removal, can solve the problems of inability to obtain a ternary solution, unfavorable environmental protection, large loss of nickel, etc., and achieve high purity and low cost. , the effect of reducing the loss of nickel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

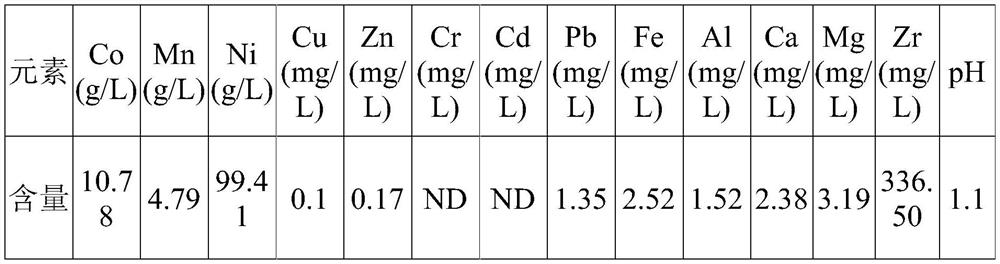

[0055] A batch of zirconium-doped ternary precursor waste was slurried with water, and the chemical composition of the solution obtained by adding sulfuric acid and hydrogen peroxide reduction leaching and filtering was shown in Table 1:

[0056] Table 1 Chemical composition list of zirconium-doped ternary precursor waste solution solution

[0057]

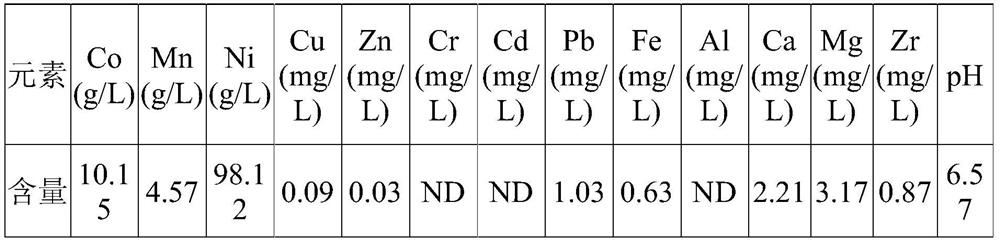

[0058] The temperature of the solution was raised to 90°C, the pH of the solution was adjusted to 6.5 with sodium hydroxide solution, stirred and reacted for 1.5 hours and filtered. The test results of the filtrate are shown in Table 2:

[0059] Table 2 Chemical composition list of liquid after zirconium removal

[0060]

[0061] It can be seen from Table 2 that after treatment, the zirconium content decreased from 336.5mg / L to 0.87mg / L, and the zirconium removal rate was 99.74%.

[0062] The obtained zirconium-nickel slag is mixed with crude nickel sulfate, leached and purified with sulfuric acid, and the nickel in the zir...

Embodiment 2

[0064] The zirconium-doped ternary precursor waste solution used in this example is the same as that in Example 1.

[0065] Heat the solution to 60°C, adjust the pH of the solution to 7 with sodium hydroxide solution, stir and react for 0.5h and filter. The test results of the filtrate are shown in Table 3:

[0066] Table 3 Chemical composition list of liquid after zirconium removal

[0067]

[0068]

[0069] It can be seen from Table 3 that after treatment, the zirconium content decreased from 336.5mg / L to 0.37mg / L, and the zirconium removal rate was 99.89%.

[0070] The obtained zirconium-nickel slag is mixed with crude cobalt hydroxide, leached and purified with sulfuric acid, and the nickel in the zirconium-nickel slag is recovered.

Embodiment 3

[0072] The zirconium-doped ternary precursor waste solution used in this example is the same as that in Example 1.

[0073] Heat the solution to 75°C, adjust the pH of the solution to 6 with sodium hydroxide solution, stir and react for 3 hours and filter. The test results of the filtrate are shown in Table 4:

[0074] Table 4 Chemical composition list of liquid after zirconium removal

[0075]

[0076] It can be seen from Table 4 that after treatment, the zirconium content decreased from 336.5mg / L to 1.12mg / L, and the zirconium removal rate was 99.67%.

[0077] The obtained zirconium-nickel slag is mixed with ternary waste, and then leached and purified with sulfuric acid to recover nickel in the zirconium-nickel slag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com