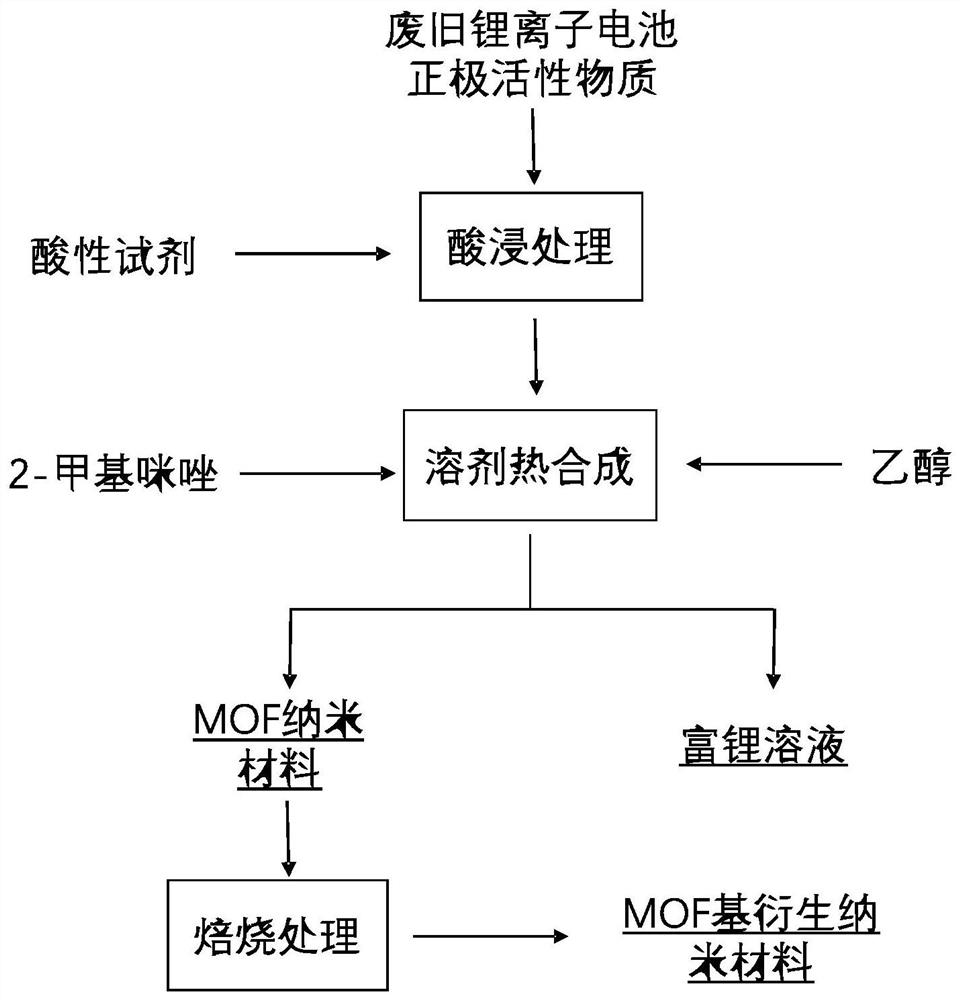

A method for preparing mof-based nanomaterials based on leaching solution of waste lithium-ion batteries

A technology for lithium ion batteries and nanomaterials, which is applied in the field of preparing MOF-based nanomaterials based on the leachate of waste lithium ion batteries, can solve the problems that the purity does not meet the requirements of commercial applications, the separation and extraction of the leachate is difficult, the utilization rate of the leachate is low, etc. Low cost, good crystallinity and complete crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for preparing MOF-based nanomaterials based on the leaching solution of waste lithium-ion batteries. The lithium-ion batteries are waste lithium cobalt oxide batteries. The method comprises the following steps:

[0036] (1) Mix the waste and old lithium-ion battery positive electrode material with the acetic acid solution of 2mol / L, add the H that the volume is 3% of acidic solution volume 2 o 2 , stirred at 70°C for 60min to obtain Li + ,Co 2+ A solution of metal ions; wherein, the solid-to-liquid ratio of the waste lithium-ion battery positive electrode material to the acidic solution is 30g / L, and the stirring speed is 400rpm.

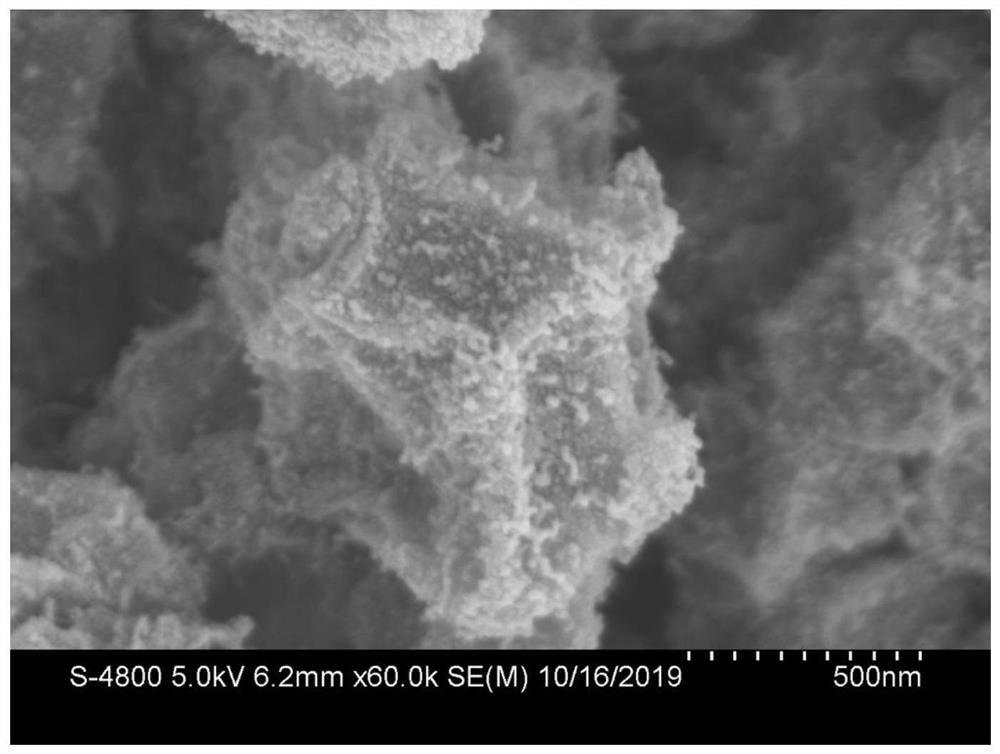

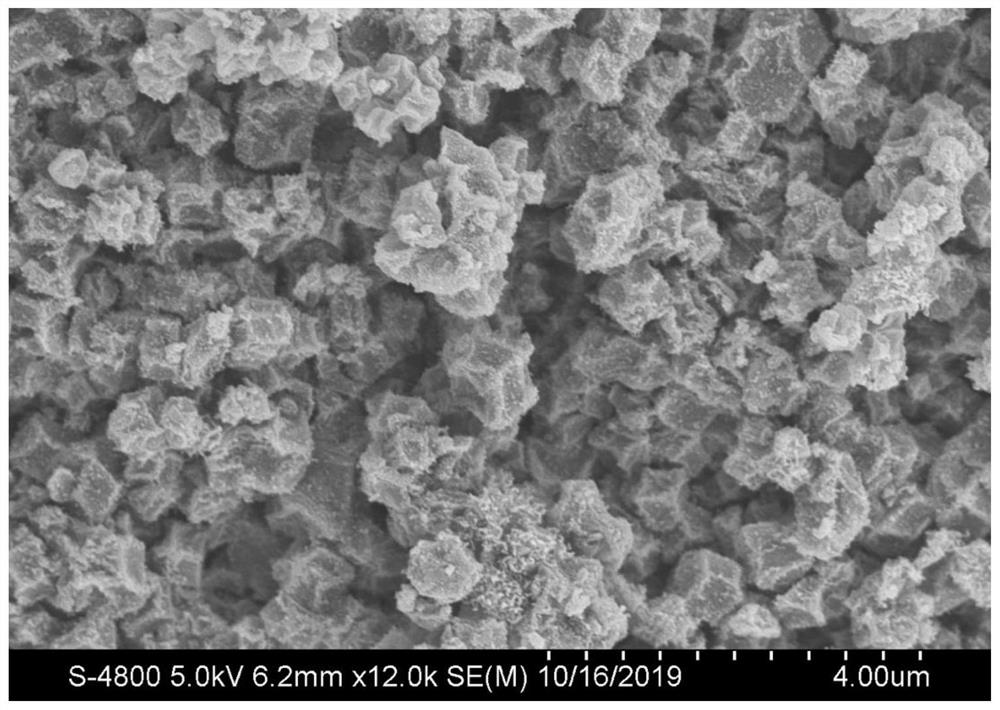

[0037] (2) Control the concentration of cobalt ions to 0.75mol / L by evaporating the leaching solution; add an appropriate amount of ammonia water to adjust the pH of the leaching solution to 6; add ethanol so that the volume ratio of the leaching solution and ethanol is 0.5:1; The molar ratio of imidazole ...

Embodiment 2

[0041] This embodiment provides a method for preparing MOF-based nanomaterials based on the leaching solution of waste lithium-ion batteries. The lithium-ion batteries are waste lithium cobalt oxide batteries. The method comprises the following steps:

[0042] (1) Mix waste and old lithium-ion battery cathode material with 1mol / L nitric acid solution, add volume is 0.5% H of acidic solution volume 2 o 2 , stirred at 50°C for 30min to obtain Li + ,Co 2+A solution of metal ions; wherein, the solid-to-liquid ratio of the waste lithium-ion battery cathode material to the acidic solution is 50g / L, and the stirring speed is 300rpm.

[0043] (2) Control the concentration of cobalt ions to 0.5mol / L by evaporating the leaching solution; add an appropriate amount of ammonia water to adjust the pH of the leaching solution to 7; add ethanol so that the volume ratio of the leaching solution and ethanol is 3:1; The molar ratio of imidazole to cobalt ion concentration was 4:1, and 2-methy...

Embodiment 3

[0047] This embodiment provides a method for preparing MOF-based nanomaterials based on the leaching solution of waste lithium-ion batteries. The lithium-ion batteries are waste lithium cobalt oxide batteries. The method includes the following steps:

[0048] (1) Mix waste and old lithium-ion battery positive electrode material with 1.5mol / L lactic acid solution, add volume and be the H of 0.5% of acidic solution volume 2 o 2 , stirred at 60°C for 30min to obtain Li + ,Co 2+ A solution of metal ions; wherein, the solid-to-liquid ratio of the waste lithium-ion battery positive electrode material to the acidic solution is 20g / L, and the stirring speed is 400rpm.

[0049] (2) Control the concentration of cobalt ions to 0.25mol / L by evaporating the leaching solution; add an appropriate amount of ammonia water to adjust the pH of the leaching solution to 10; add ethanol so that the volume ratio of the leaching solution and ethanol is 1:1; The molar ratio of imidazole to cobalt i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com