Glass cutting robot

A glass cutting and robot technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as low efficiency, glass cutting tilt, glass use waste, etc., to achieve accuracy and precision improvement, and ensure accuracy , High cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

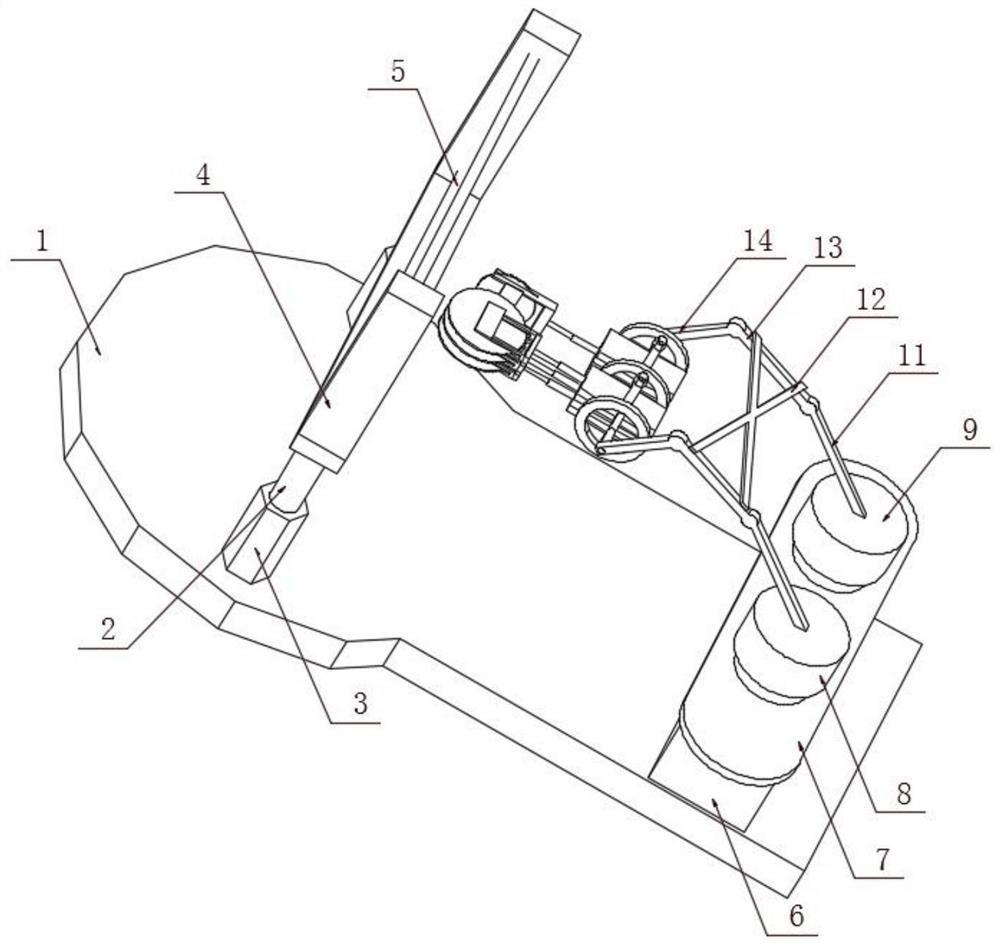

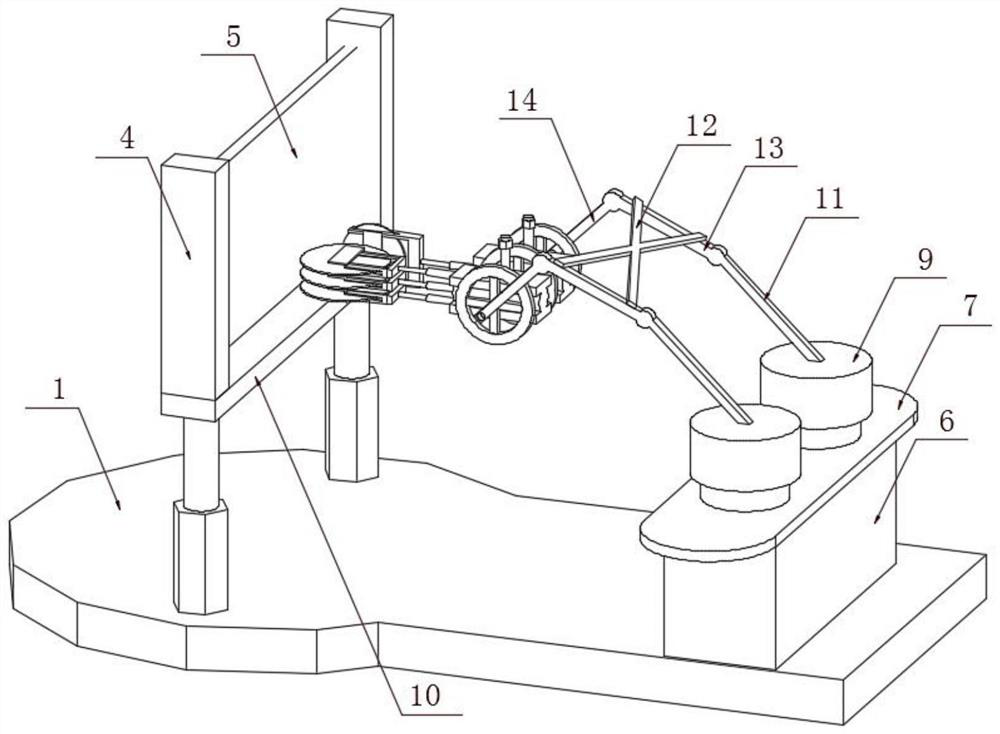

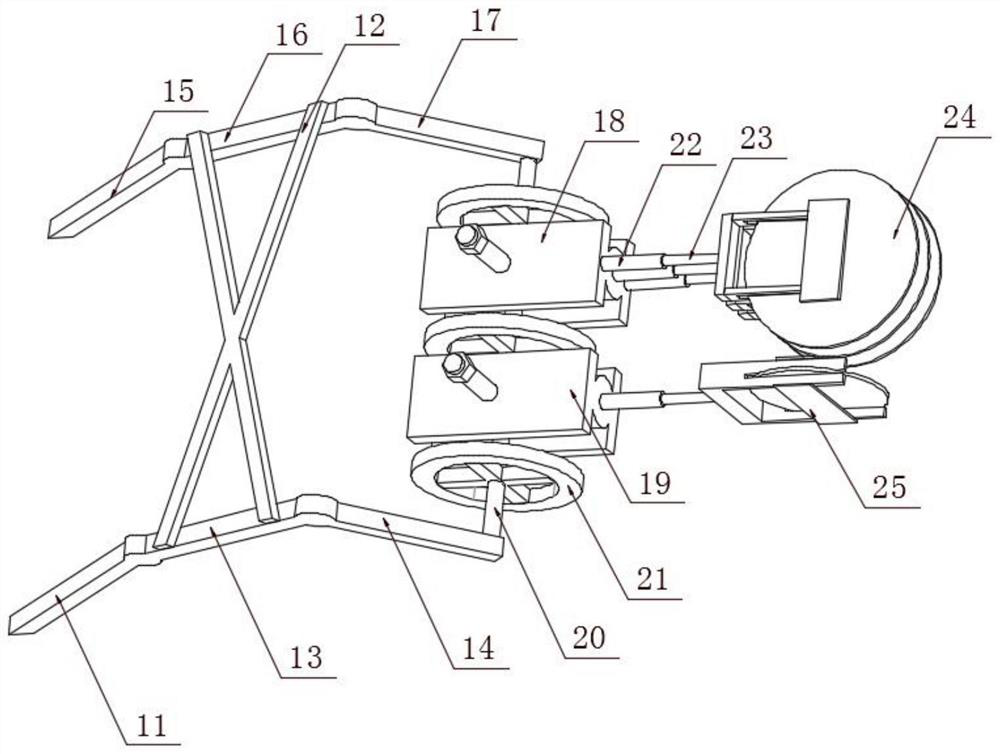

[0027] see Figure 1-6, in the embodiment of the present invention, the robot for glass cutting includes a fixed base 1, a fixed mounting plate 7, a mechanical tail arm A11 and a mechanical tail arm B15, the top surface of the fixed base 1 is welded with a pneumatic cylinder 3, and the fixed base 1 can play The function of fixing, the top surface of the pneumatic cylinder 3 is sleeved with the pneumatic strut 2, the pneumatic cylinder 3 ensures that the pneumatic strut 2 moves up and down, and the other end of the pneumatic strut 2 is welded with a clamping base plate 10, and the clamping base plate 10 The top surface is welded with a clamping side plate 4, and the top surface of the fixed base 1 is welded with a circuit box 6. The top surface of the circuit box 6 is provided with a fixed mounting plate 7. The circuit box 6 can realize the control of the entire circuit, and the fixed mounting plate 7 Rotation controller A8 and rotation controller B9 are plugged in on the top s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com