Pumped storage unit water pump working condition hump area stability evaluation method considering dynamic characteristics

A pumped storage unit, stability technology, applied in computer-aided design, calculation, design optimization/simulation, etc., can solve problems such as potential safety hazards of power stations, failure to consider the influence of dynamic characteristics of water transmission and power generation systems, and unit operation entering the hump area. , to achieve an accurate assessment of the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

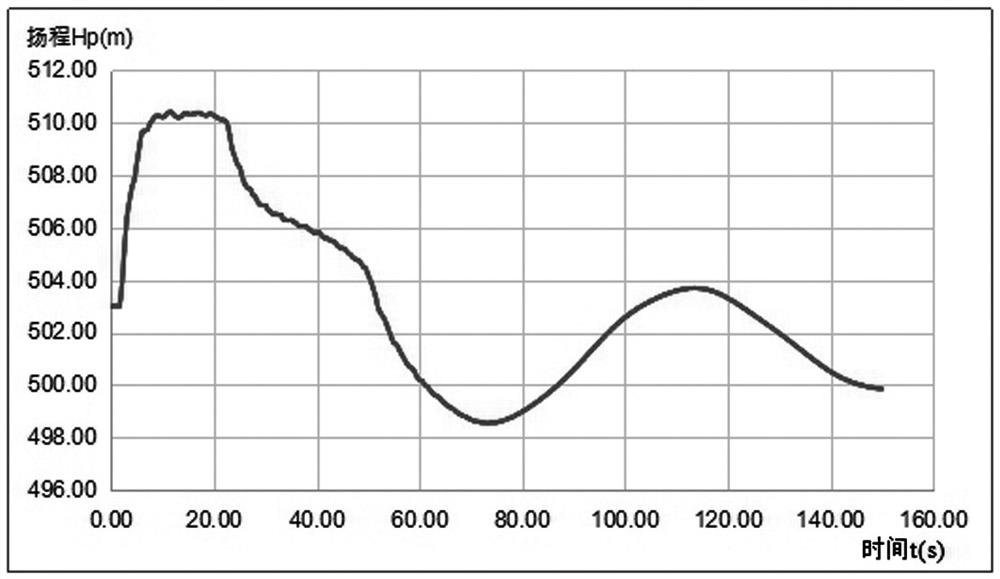

[0015]This embodiment is a method for evaluating the stability of the hump region of the pumped storage unit under pump working conditions that takes into account dynamic characteristics. The specific steps are as follows:

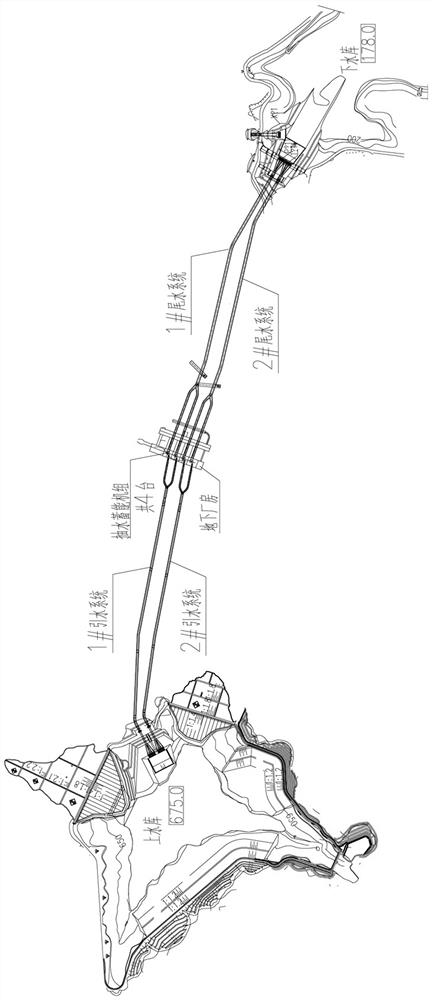

[0016]A. According to the layout of the water transmission and power generation system, select several working conditions corresponding to the high-lift operation transition process of the unit's water pump working conditions; including independent working conditions and combined working conditions. The selected working condition needs to be able to produce the maximum dynamic head of the unit, that is, the maximum pressure difference between the outlet and the inlet of the pump-turbine pump working condition. When the layout of the water transmission and power generation system is different, the selected working conditions are correspondingly different:

[0017](1) For the layout type of the water transmission power generation system with a single pipe and a single u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com