Self-purification silicon wafer transportation device

A transportation device and self-purification technology, applied in transportation and packaging, conveyor objects, electrical components, etc., can solve the problems of reduced silicon wafer performance, silicon wafer damage, etc., to avoid pollution, reasonable structure, and dust isolation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

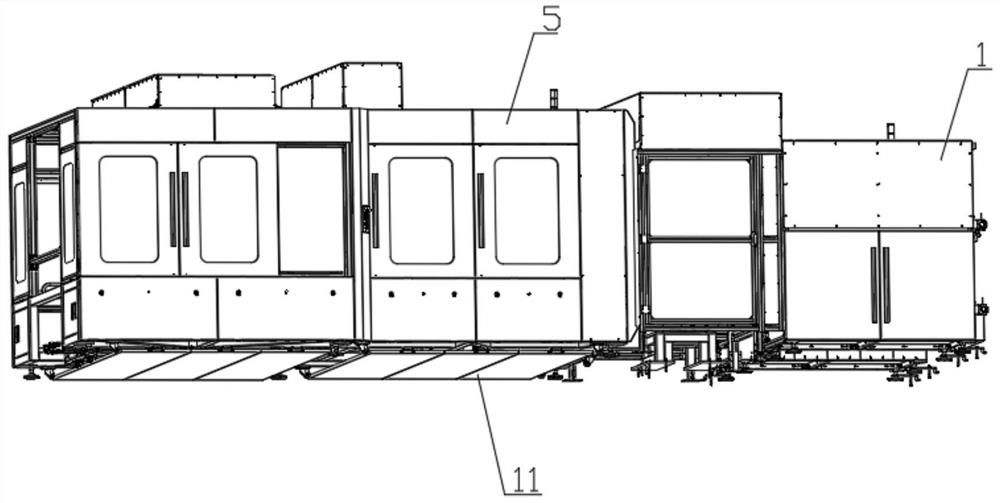

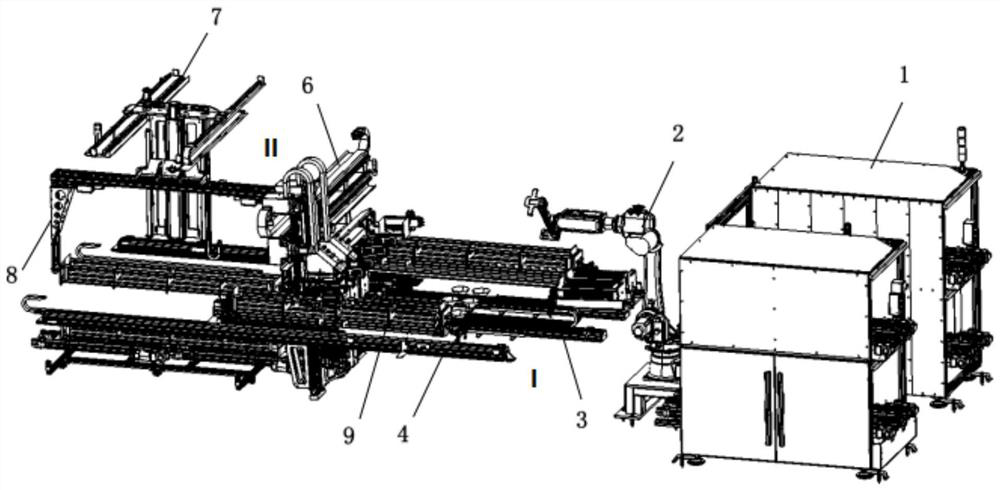

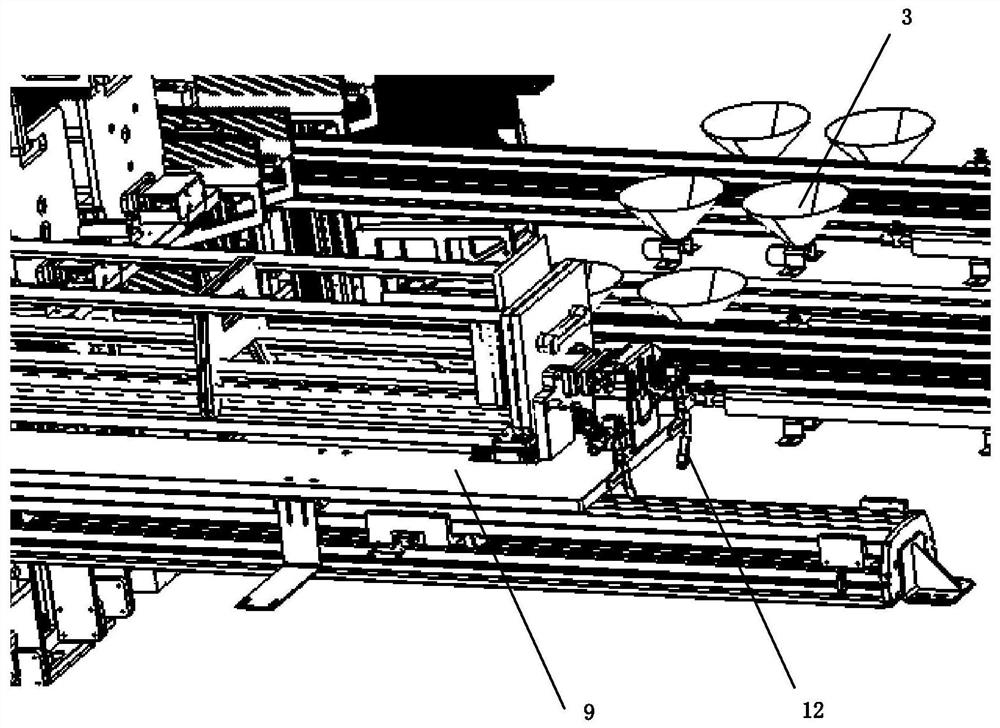

[0032] refer to figure 1 As shown, an embodiment of the present invention includes a symmetrically arranged conveying device 1, a dust-proof frame 5 is arranged on one side of the conveying device 1, and a manipulator is arranged in the middle of the dust-proof frame 5 on one side of the two conveying devices 1. 2. One side of the manipulator 2 is provided with an adsorption and purge runway 3, and both sides of the adsorption and purge runway 3 are provided with a dust-proof runway 4. A grabbing device 6 is arranged above the runway 4, and a truss 7 is arranged on one side of the grabbing device 6 inside the dust-proof frame 5, and a gripper 8 is arranged on the truss 7; On the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com