Pipe inner wall cleaning system and method

A technology for cleaning systems and pipes, applied in cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of low efficiency, high energy consumption, inconvenient operation, etc., to improve the operating environment and ensure the cleaning effect. , good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solutions in the embodiments of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the specific implementation of the present invention will be further described below in conjunction with the accompanying drawings illustrate.

[0038] It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not conflict with each other.

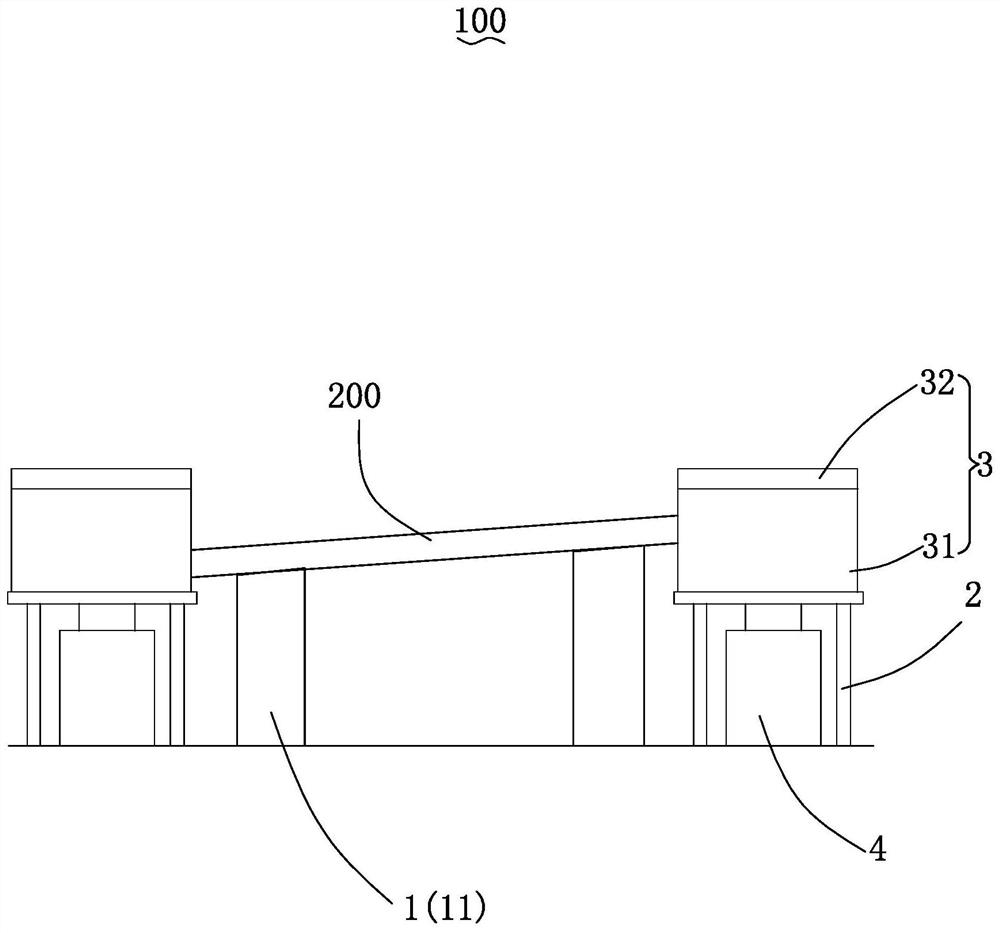

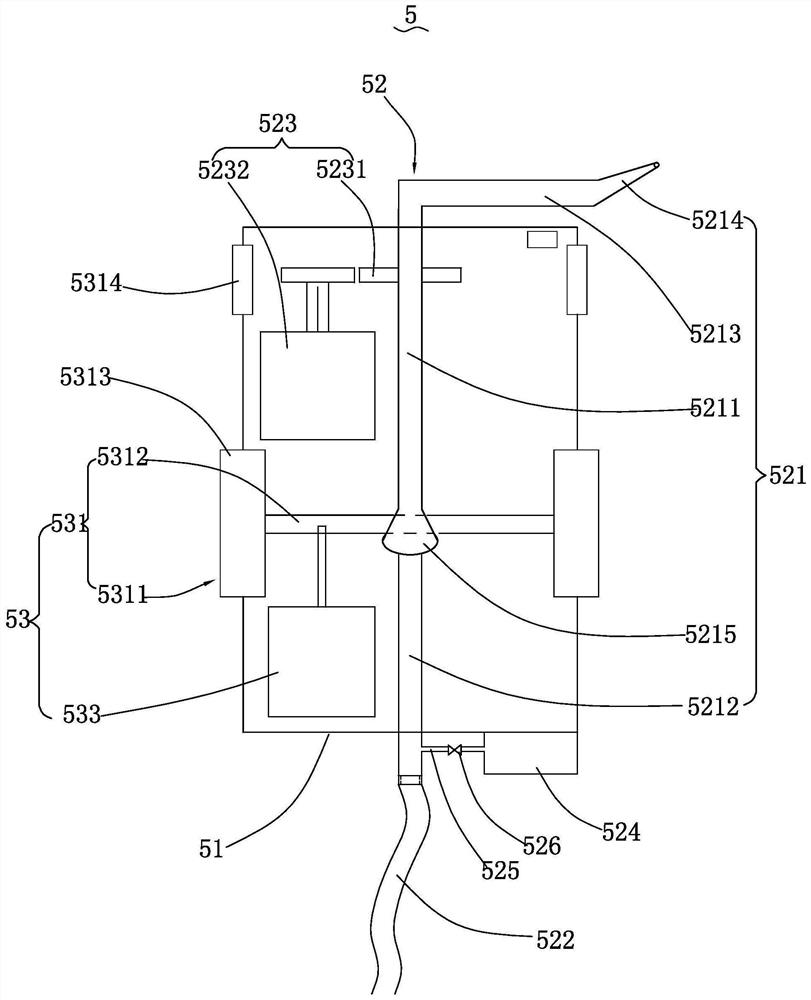

[0039] Please refer to figure 1 and figure 2 ,in figure 1 It is a partial structural schematic diagram of the pipe inner wall cleaning system provided by the present invention, figure 2 It is a structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap