Grinding device for metal tool machining

A metal tool and grinding wheel technology, applied in the field of grinding devices for metal tool processing, can solve problems such as insufficient smoothness and unreliable grinding, and achieve the effects of avoiding manual errors, improving efficiency, and avoiding environmental interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

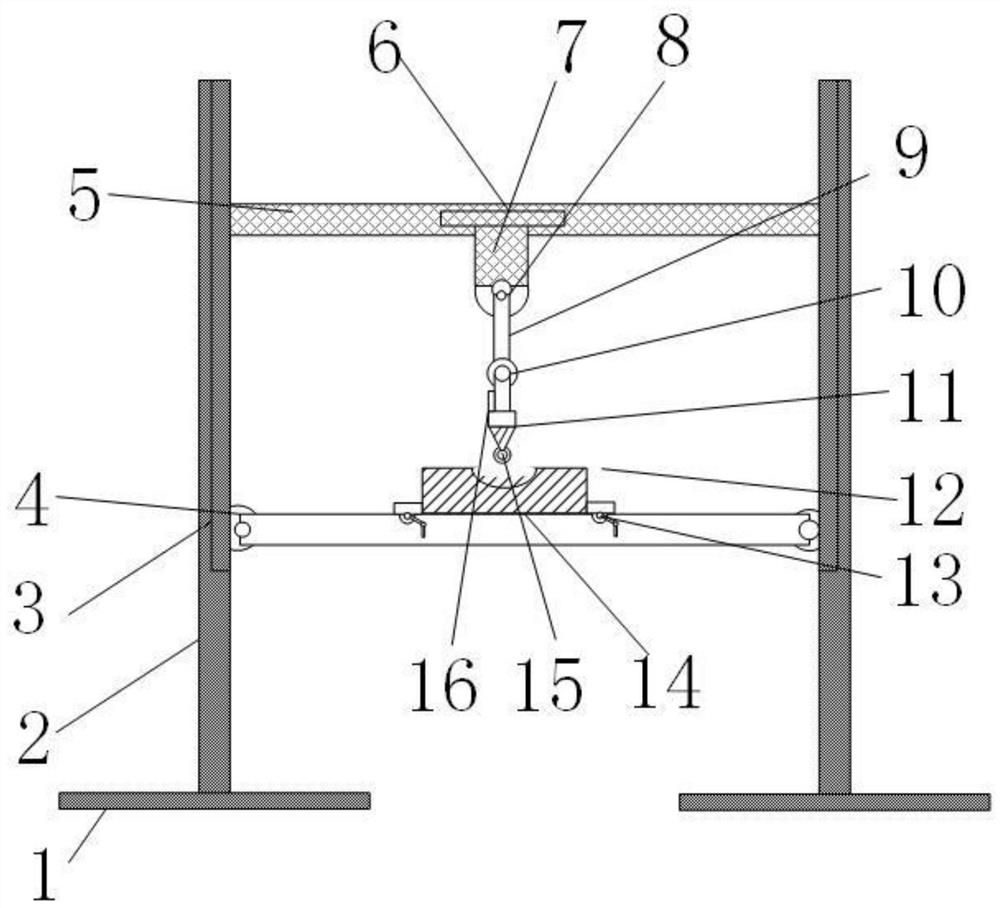

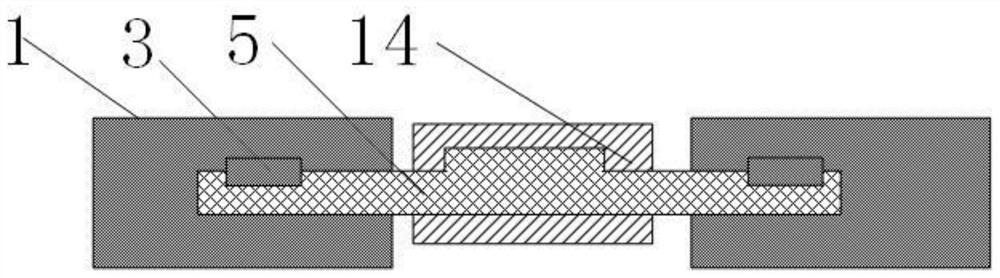

[0023] As a preferred embodiment of the present invention, the number of the charging stand 16 is specifically one, and an empty groove is opened on the edge of the grinding box 12 .

[0024] As a preferred embodiment of the present invention, the bearing frame 2 is made of aluminum alloy material with certain toughness, and the left and right pulleys 10 are roller structures with a diameter of ten centimeters.

[0025] Main features of the present invention: the new type of grinding device for metal tool processing has a certain degree of reliability by providing a support plate 1 and a load-bearing frame 2, which can ensure reliable grinding of metal tool parts and avoid environmental interference.

[0026] This new type of grinding device for metal tool processing can control the height and operation parameters of the grinding through the hanging plate 7 and the left and right pulleys 10, and can well meet the metal tool industry standards, thereby avoiding manual errors.

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap