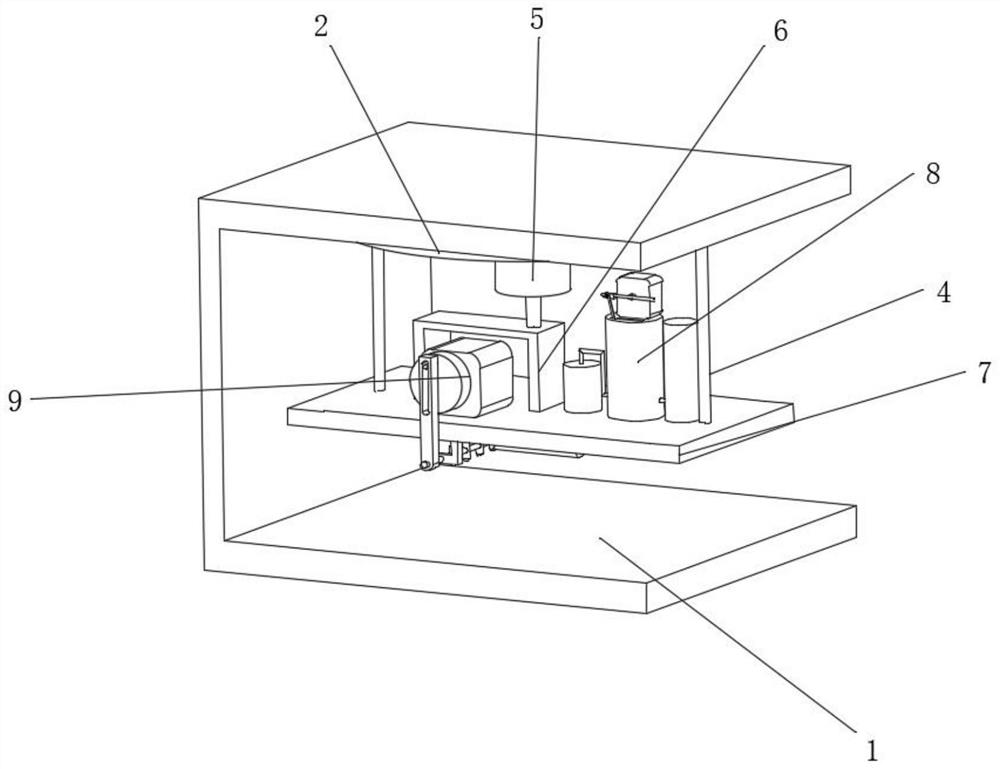

Automatic spraying device for lifting process of wire cutting machine

An automatic spraying and wire-cutting technology, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of insufficient spraying effect, spraying dead angle, small spraying area, etc., and achieve good spraying The effect of spraying and sweeping, adapting to line cutting operations, and avoiding dead ends of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

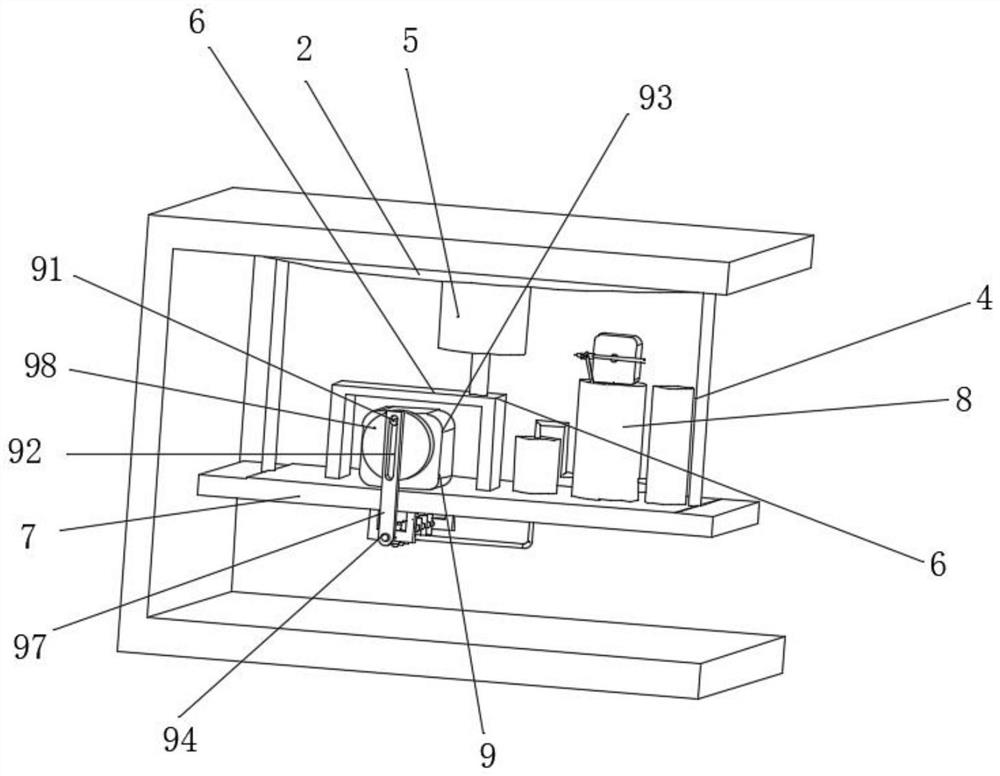

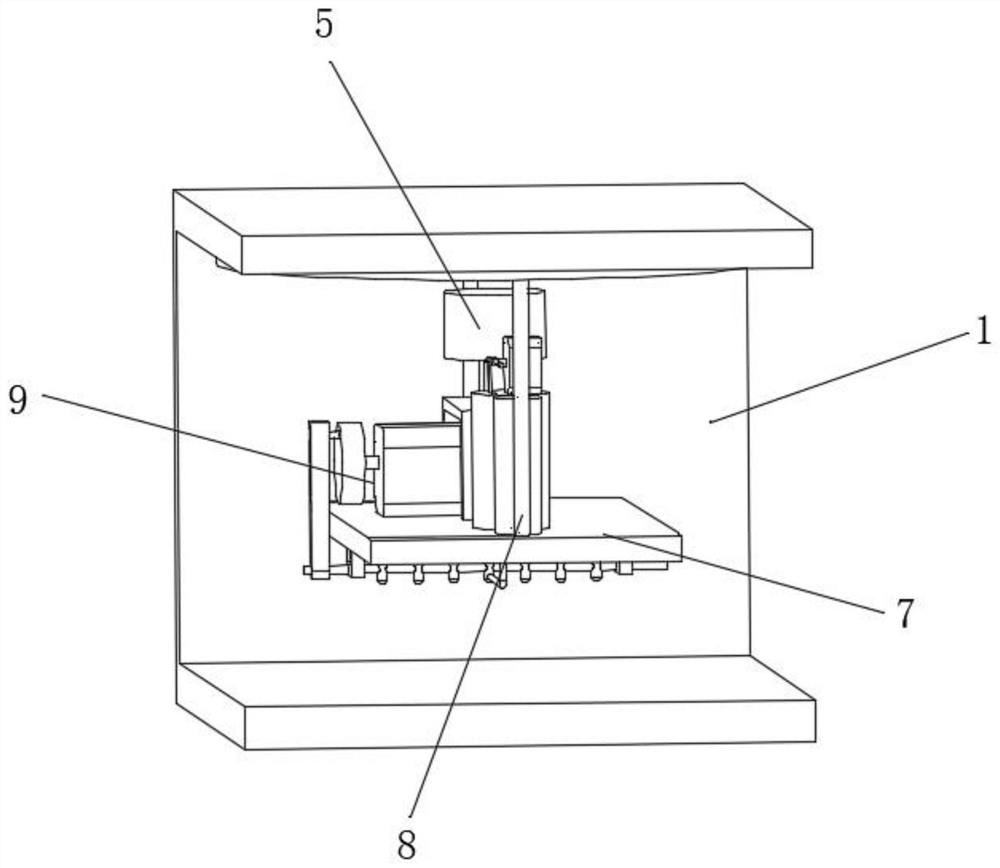

[0028] As an embodiment of the present invention, the spraying structure 9 includes a toggle lever 91, a slide hole 92, a swing motor 93, a swing shaft 94, a spray head 95, a swing frame 96, a swing lever 97 and a rotating disk 98. The motor 93 is mounted on the top side of the support plate 7 through bolts. The rotating shaft of the swing motor 93 is fitted with a rotating disk 98. The eccentric position of the end face of the rotating disk 98 is welded with a toggle lever 91. The swing frame 96 is welded on the bottom side of the support plate 7, and the swing shaft 94 is installed in the swing frame 96 through bearings. The circumferential surface of the swing shaft 94 is equipped with a plurality of shower heads 95 in parallel. The bottom end of the swing rod 97 It is welded on one end of the swing shaft 94 , and the top of the swing rod 97 is provided with a slide hole 92 .

[0029] As an embodiment of the present invention, the toggle rod 91 is fitted in the slide hole 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com