Method for rapidly synthesizing La2(MoO4)3: Eu<3+> nanometer fluorescent powder at low temperature

A technology of nano-fluorescent powder and fluorescent powder, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of a large amount of power, time and intermediate grinding, is not suitable for industrial production, and has high temperature requirements, and meets the requirements of preparation schedule. The effect of harshness, high yield and yield, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

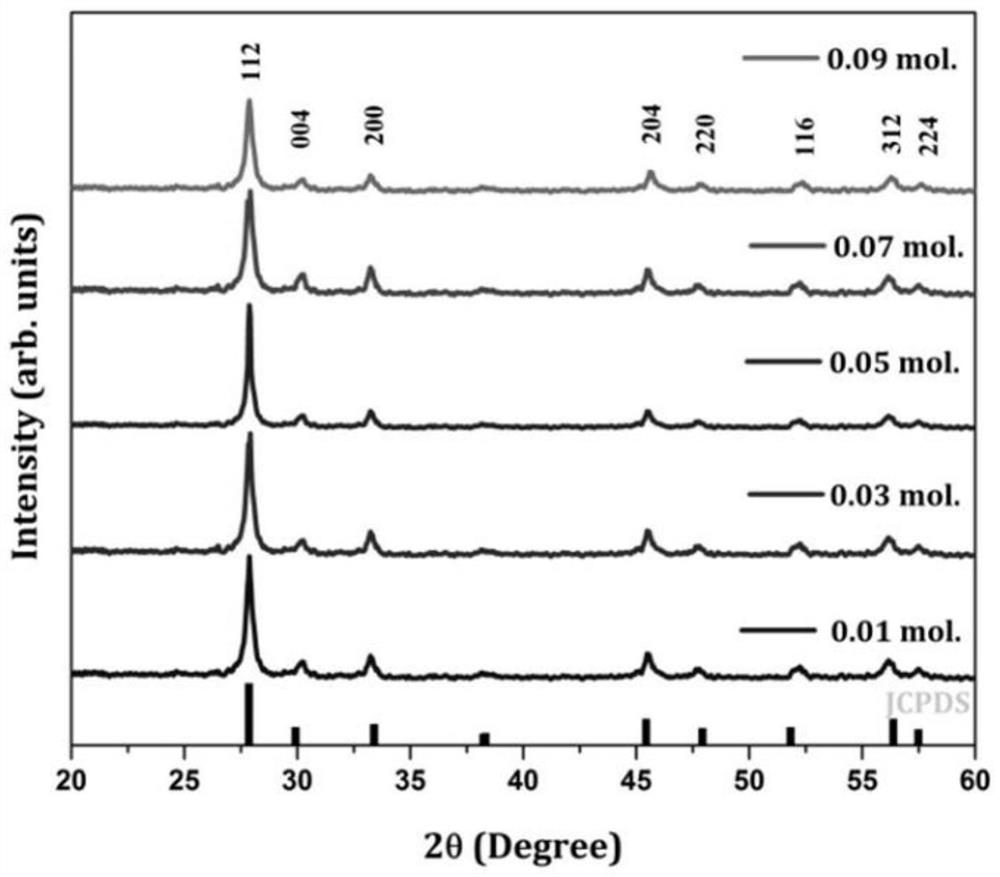

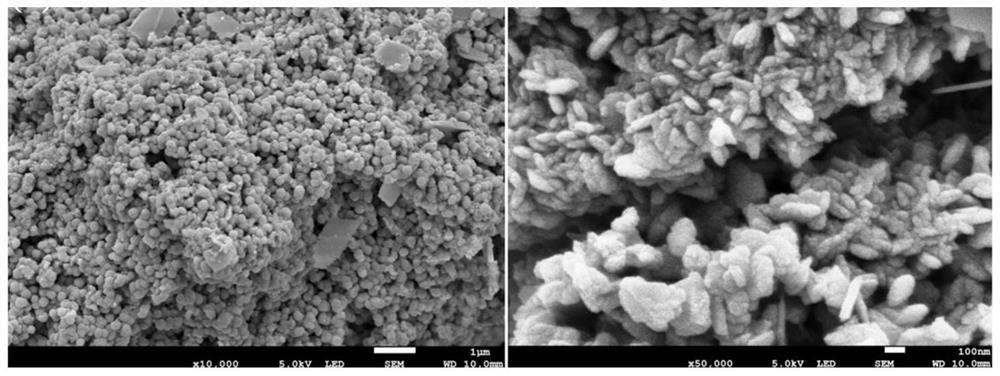

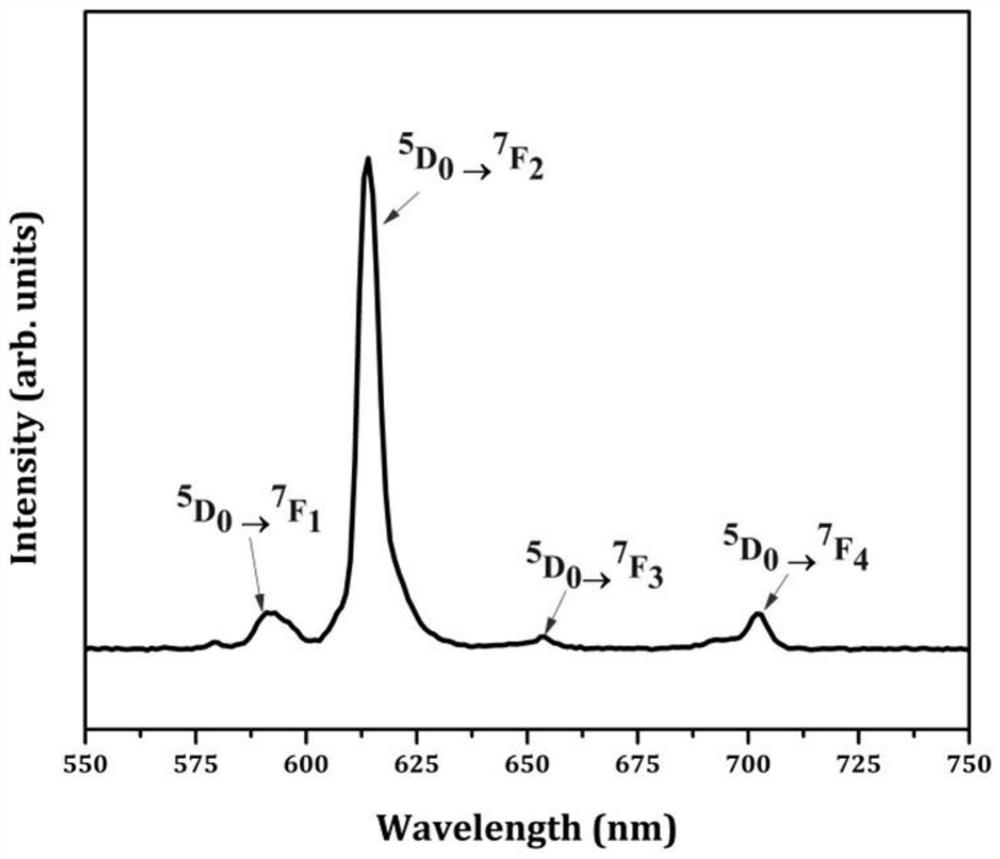

[0014] Example 1: La 2 (MoO 4 ) 3 :0.01Eu 3+

[0015] First, weigh Na with a purity greater than 99.9% according to the stoichiometric ratio 2 MoO 4 、LaCl 3 , EuCl 3 , in a planetary ball mill for 3 hours of ball milling. Then the raw materials were ground, washed with deionized water and absolute ethanol for 3 to 4 times respectively, and then dried at 80°C for 2 h to obtain the nano phosphor.

Embodiment 2

[0016] Example 2: La 2 (MoO 4 ) 3 :0.03Eu 3+

[0017] First, weigh Na with a purity greater than 99.9% according to the stoichiometric ratio 2 MoO 4 、LaCl 3 , EuCl 3 , in a planetary ball mill for 1 hour of ball milling. Then the raw materials were ground, washed with deionized water and absolute ethanol for 3 to 4 times respectively, and then dried at 60°C for 5 hours to obtain the nano phosphor.

Embodiment 3

[0018] Example 3: La 2 (MoO 4 ) 3 :0.05Eu 3+

[0019] First, weigh Na with a purity greater than 99.9% according to the stoichiometric ratio 2 MoO 4 、LaCl 3 , EuCl 3 , in a planetary ball mill for 2 hours of ball milling. Then the raw materials were ground, washed with deionized water and absolute ethanol for 3-4 times respectively, and then dried at 70°C for 3 hours to obtain nano phosphors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com