Fluorescent powder with high thermal stability for white light LED

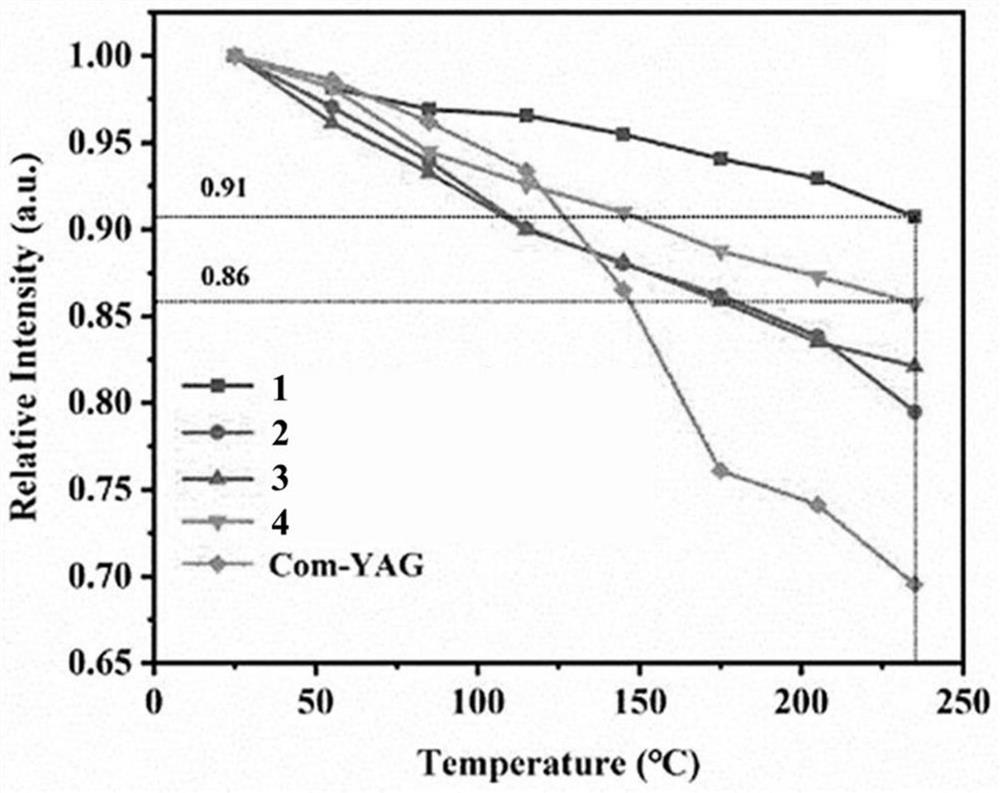

A technology of high thermal stability and phosphor powder, applied in the field of phosphor powder, can solve the problems of very sensitive surrounding environment, re-absorption of phosphor powder, color drift, etc., and achieve the effects of excellent thermal stability, simple preparation process and lower production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Ba 19 Li 2 Mg(PO 4 ) 14 : 0.005Dy 3+ , 0.01Tm 3+

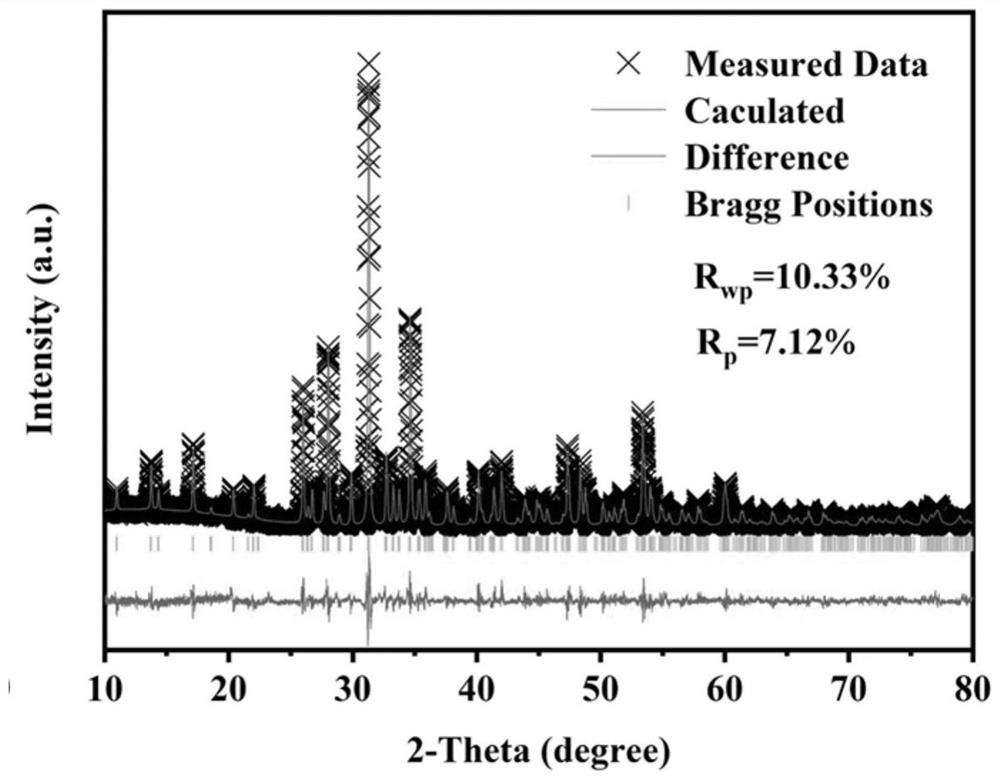

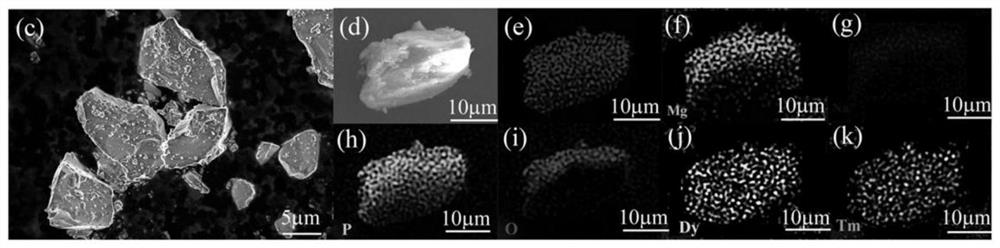

[0016] Firstly, Li with a purity greater than 99.9% was weighed according to the stoichiometric ratio. 2 O, BaCO 3 , MgCO 3 , (NH 4 ) 2 HPO 4 、Tm 2 o 3 and Dy 2 o 3 , after mixing well, grind in an agate mortar. Then, the mixed raw materials were calcined at 1350° C. for 4 hours, finally cooled to room temperature gradually, and ground again to obtain the phosphor powder.

Embodiment 2

[0017] Example 2: Ba 19 Li 2 Mg(PO 4 ) 14 : 0.01Dy 3+ , 0.01Tm 3+

[0018] Firstly, Li with a purity greater than 99.9% was weighed according to the stoichiometric ratio. 2 O, BaCO 3 , MgCO 3 , (NH 4 ) 2 HPO 4 、Tm 2 o 3 and Dy 2 o 3 , after mixing well, grind in an agate mortar. Then, the mixed raw materials were calcined at 1100° C. for 8 hours, finally cooled to room temperature gradually, and grinded again to obtain the phosphor powder.

Embodiment 3

[0019] Example 3: Ba 19 Li 2 Mg(PO 4 ) 14 : 0.03Dy 3+ , 0.01Tm 3+

[0020] Firstly, Li with a purity greater than 99.9% was weighed according to the stoichiometric ratio. 2 O, BaCO 3 , MgCO 3 , (NH 4 ) 2 HPO 4 、Tm 2 o 3 and Dy 2 o 3 , after mixing well, grind in an agate mortar. Then, the mixed raw materials were calcined at 1200° C. for 5 hours, finally cooled to room temperature gradually, and ground again to obtain the phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com