Method for producing astaxanthin from chromochloris zofingiensis

An astaxanthin and green algae technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of easy contamination, hindering astaxanthin, and long cultivation time, so as to shorten the cultivation time and improve the Production efficiency, the effect of improving yield and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

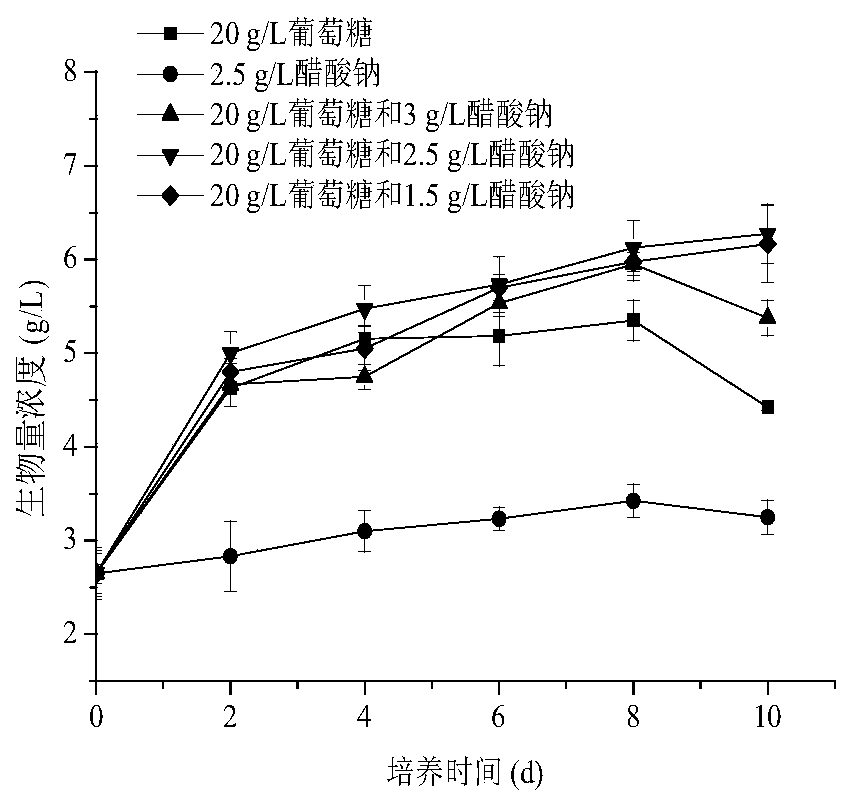

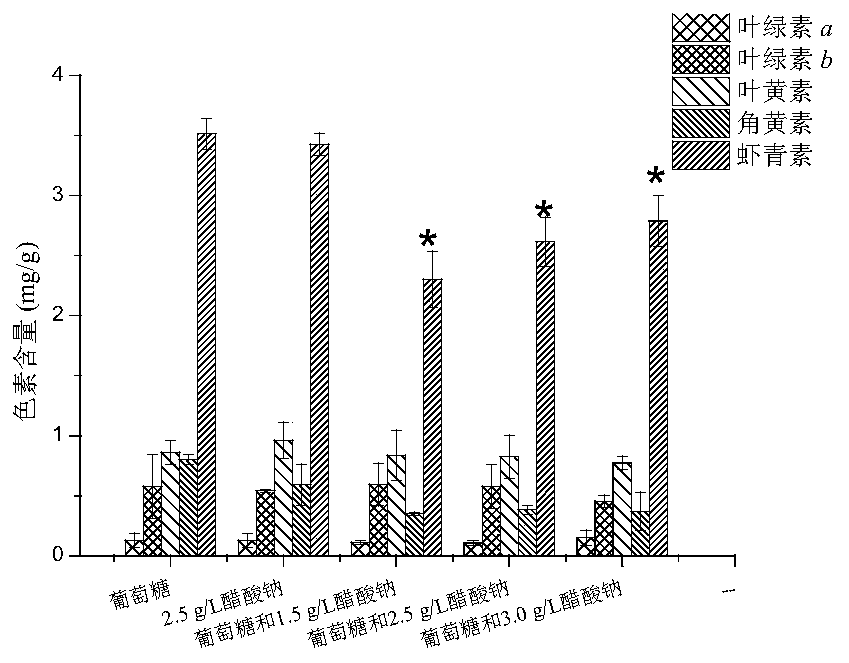

[0042] 1. Effects of mixed carbon sources on the accumulation of astaxanthin in Chlorella zoffensis

[0043] 1.1 Algae activation and rapid preparation of seed solution

[0044] Pick a single algae colony from the medium plate, inoculate it into a 250mL Erlenmeyer flask of Bristol’s medium containing 10g / L glucose (the filling volume is 100mL), and inoculate it under the light of 10μmol.m -2 .s -1 , in a constant temperature incubator with a temperature of 26° C. and a rotational speed of 150 r / min for continuous cultivation for 4-5 days.

[0045] The above-mentioned activated seed solution was inserted into Bristol medium (seeding density was 2.30g / L), wherein the glucose concentration in the medium was 30g / L, sodium nitrate was the carbon source, and the carbon-nitrogen ratio was 34. In the light of 10μmol.m -2 .s -1 , and cultivated in a constant temperature incubator with a temperature of 26°C and a rotation speed of 150r / min.

[0046] 1.2 Effects of mixed carbon sour...

Embodiment 2

[0055] 2. The effect of inoculation density on the accumulation of astaxanthin in Chlorella zoffii

[0056] 2.1 Algae activation and rapid preparation of seed solution

[0057] The activation of Chlorella zoff and the rapid preparation of the seed solution were as described in 1.1.

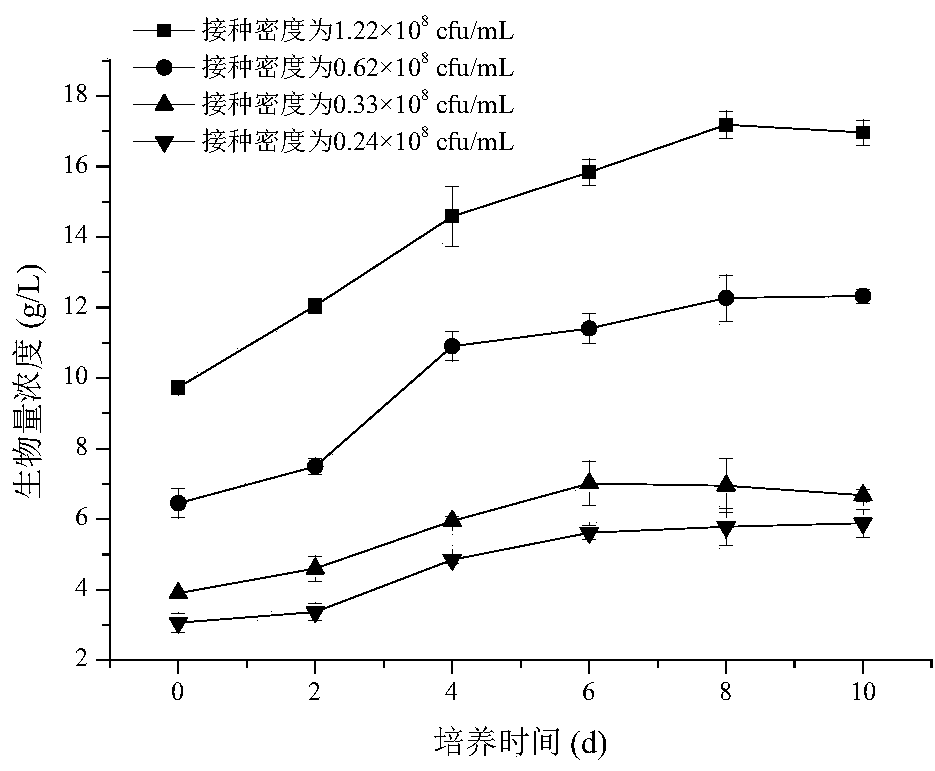

[0058] 2.2 The effect of inoculation density on the accumulation of astaxanthin in Chlorella zoffii

[0059] Nitrogen-free Britol medium was used as the basic medium, the initial glucose concentration was 20g / L, and the inoculation density was set to: 1.22×10 8 , 0.61×10 8 , 0.32×10 8 and 0.24×10 8 cfu / mL. Other culture conditions are the same as those described in 1.2.

[0060] After the cultivation, the biomass concentration of the green algae cells was measured; centrifuged to collect, the supernatant was removed, the algae mud was collected and freeze-dried, and the pigment composition in the algae cells was analyzed.

[0061] 2.3 Experimental results

[0062] from Figure 2a-2b And T...

Embodiment 3

[0068] 3. The effect of light intensity on the accumulation of astaxanthin in Chlorella zoffii

[0069] 3.1 Algal seed activation and rapid preparation of seed solution

[0070] The activation of Chlorella zoff and the rapid preparation of the seed solution were as described in 1.1.

[0071] 3.2 The effect of light intensity on the accumulation of astaxanthin in Chlorella zoffii

[0072] Nitrogen-free Britol medium was used as the basic medium, the initial glucose was 20g / L, and the light gradient was set to: 88±8, 160±5, 240±6 and 320±5μmol.m -2 .s -1 Other culture conditions are the same as those described in 1.2.

[0073] After the cultivation, the biomass concentration of the green algae cells was measured; centrifuged to collect, the supernatant was removed, the algae mud was collected and freeze-dried, and the pigment composition in the algae cells was analyzed.

[0074] 3.3 Experimental results

[0075] from Figure 3a-3b And Table 3 shows that when the light inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inoculation density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com