Cu<2+>-doped BaAl2O4 fluorescent powder and preparation method thereof

A technology of phosphor powder and sol-gel method, which is applied in the field of luminescent material preparation and application, can solve the problems of unfavorable barium aluminate luminescence characteristics, etc., and achieve the requirements of less stringent preparation schedule, high output and yield, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

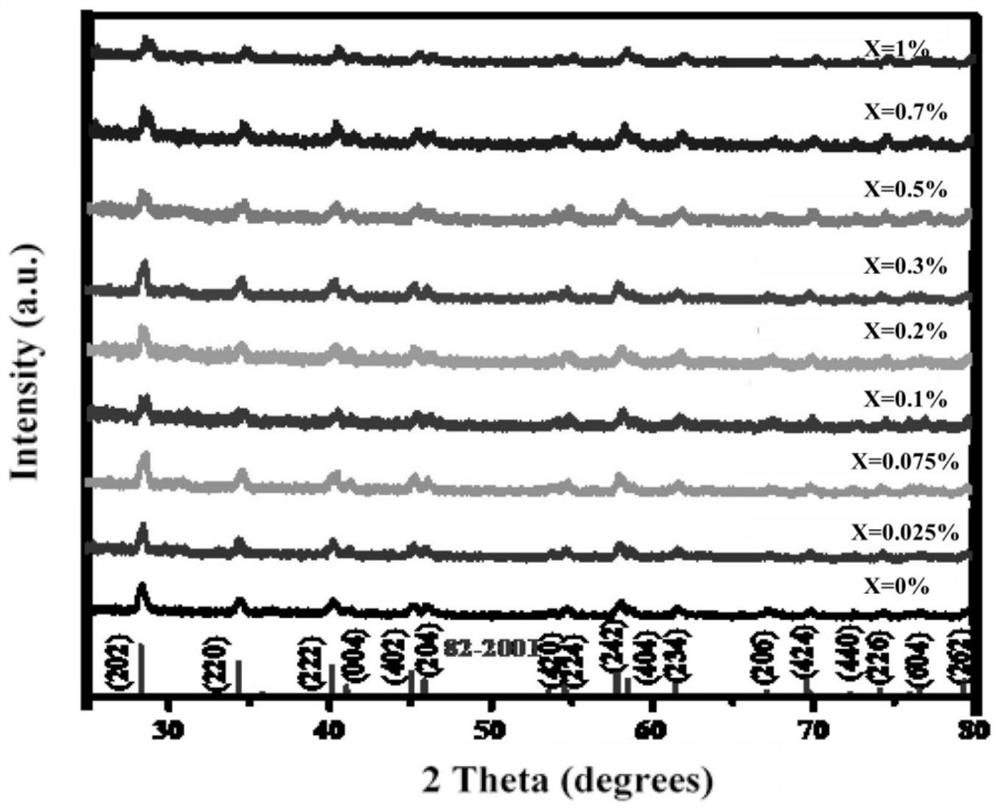

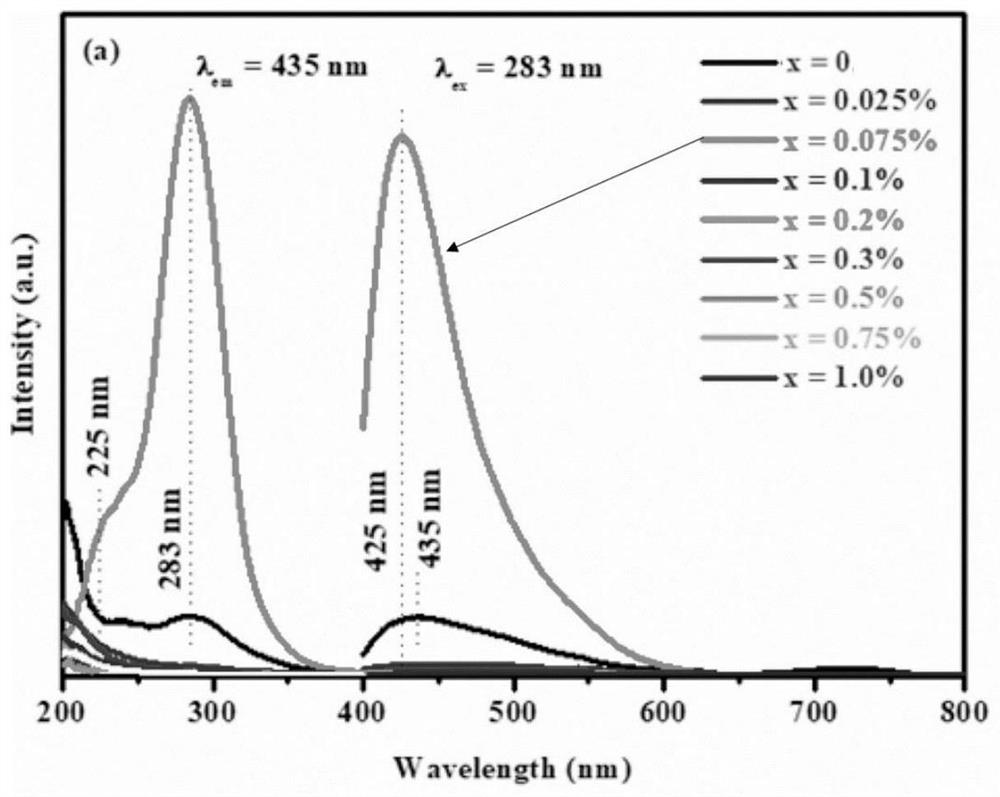

[0015] Example 1: BaAl 2 o 4 :1 mol% Cu 2+

[0016] Barium nitrate, aluminum nitrate and copper nitrate with a purity greater than 99.9% were weighed as raw materials according to the stoichiometric ratio. First, the raw materials are added to citric acid, the molar ratio of citric acid to metal ions is 1:0.5, and then deionized water with a volume fraction of citric acid of 50% is added to obtain a sol. Then the sol was placed on a magnetic stirrer and heated at 75° C. with constant stirring at 300 rpm to form a gel. Then, the gel was dried at room temperature for 8 hours. Finally, the gel was calcined at 1000° C. for 2 hours, and then ground to obtain the phosphor.

Embodiment 2

[0017] Example 2: BaAl 2 o 4 :0.7mol% Cu 2+

[0018] Barium nitrate, aluminum nitrate and copper nitrate with a purity greater than 99.9% were weighed as raw materials according to the stoichiometric ratio. First, the raw materials were added to citric acid, the molar ratio of citric acid to metal ions was 1:2, and then deionized water with a volume fraction of citric acid of 30% was added to obtain a sol. Then the sol was placed on a magnetic stirrer and heated at 90° C. with constant stirring at 200 rpm to form a gel. Then, the gel was dried at room temperature for 12 hours. Finally, the gel was calcined at 800° C. for 4 hours, and then ground to obtain the phosphor.

Embodiment 3

[0019] Example 3: BaAl 2 o 4 :0.5mol% Cu 2+

[0020] Barium nitrate, aluminum nitrate and copper nitrate with a purity greater than 99.9% were weighed as raw materials according to the stoichiometric ratio. First, the raw materials are added to citric acid, the molar ratio of citric acid to metal ions is 1:1, and then deionized water with a volume fraction of citric acid of 40% is added to obtain a sol. Then the sol was placed on a magnetic stirrer and heated at 80° C. with constant stirring at 250 rpm to form a gel. Then, the gel was dried at room temperature for 10 hours. Finally, the gel was calcined at 900° C. for 3 hours, and then ground to obtain the phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com