Synchronous extracting and fermenting method for preparing natural astaxanthin and other carotenoids

A technology of natural astaxanthin and carotene, which is applied in the field of simultaneous extraction and fermentation for the preparation of natural astaxanthin and other carotenoids, can solve the problems of high production cost, increased separation cost, and difficulty in extraction, so as to increase production and production Efficiency, simplification of the subsequent purification process, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

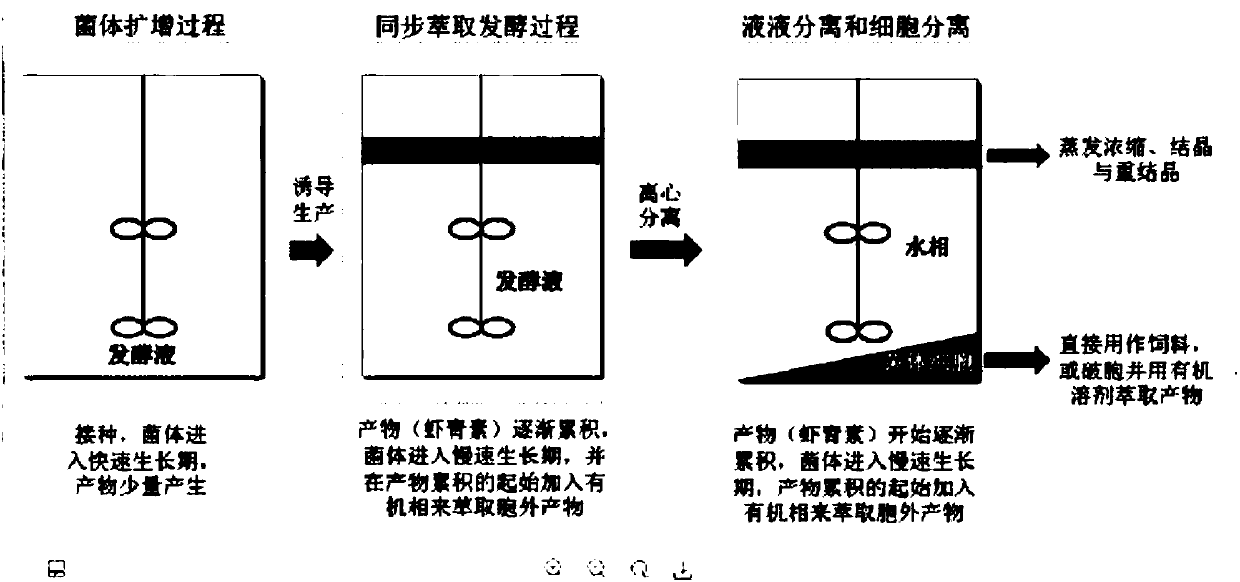

Method used

Image

Examples

Embodiment 1

[0026] Step 1) prepare 5L culture medium, comprise 10g / L glucose, 2g / L (NH 4 ) 2 SO 4 , 4.2g / L KH 2 PO 4 and 11.24g / L K 2 HPO 4 , 1.7g / L citric acid, 0.5g / L MgSO 4 And 10mL / L trace element solution. Among them, the trace element solution contains 0.25g / L CoCl 2 ·6H 2 O, 1.5g / L MnSO 4 4H 2 O, 0.15g / L CuSO 4 2H 2 O, 0.3g / L H 3 BO 3 , 0.25g / LNa 2 MoO4· 2 h 2 O, 0.8g / L Zn(CH 3 COO) 2 , 5g / L iron (III) citrate and 0.84g / L EDTA, the pH of the trace element solution is 8.0.

[0027] Step 2) Sterilize the culture medium at 121° C. for 15-20 minutes. (Note, the glucose solution should be sterilized separately before mixing with other ingredients).

[0028] Step 3) Next, take 100mL of culture medium and put them into identical #1 and #2, two 250mL fermentors, and place the fermentors at a temperature of 121°C.

[0029] Step 4) Inoculate the Escherichia coli strain E with high astaxanthin production through genetic engineering into 20mL medium (the medium is taken f...

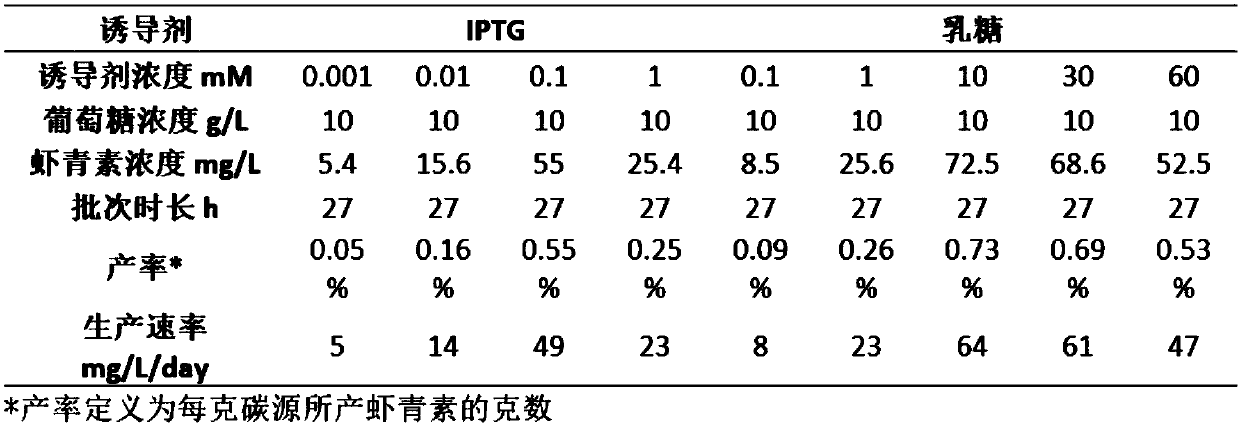

Embodiment 2

[0035] Step 1) prepare 5L culture medium, comprise 10g / L glucose, 2g / L (NH 4 ) 2 SO 4 , 4.2g / L KH 2 PO 4 and 11.24g / L K 2 HPO 4 , 1.7g / L citric acid, 0.5g / L MgSO 4 And 10mL / L trace element solution. Among them, the trace element solution contains 0.25g / L CoCl 2 ·6H 2 O, 1.5g / L MnSO 4 4H 2 O, 0.15g / L CuSO 4 2H 2 O, 0.3g / L H 3 BO 3 , 0.25g / LNa 2 MoO4· 2 h 2 O, 0.8g / L Zn(CH 3 COO) 2 , 5g / L iron (III) citrate and 0.84g / L EDTA, the pH of the trace element solution is 8.0.

[0036] Step 2) Sterilize the culture medium at 121° C. for 15-20 minutes. (Note, the glucose solution should be sterilized separately before mixing with other ingredients).

[0037] Step 3) Next, take 100mL of medium and put them into identical #3 fermenter, #4 fermenter, #5 fermenter, and #6 fermenter, all of which are 250mL fermenters, and put the fermentors into Placed at a temperature of 121°C.

[0038] Step 4) Inoculate the Escherichia coli strain E with high astaxanthin production th...

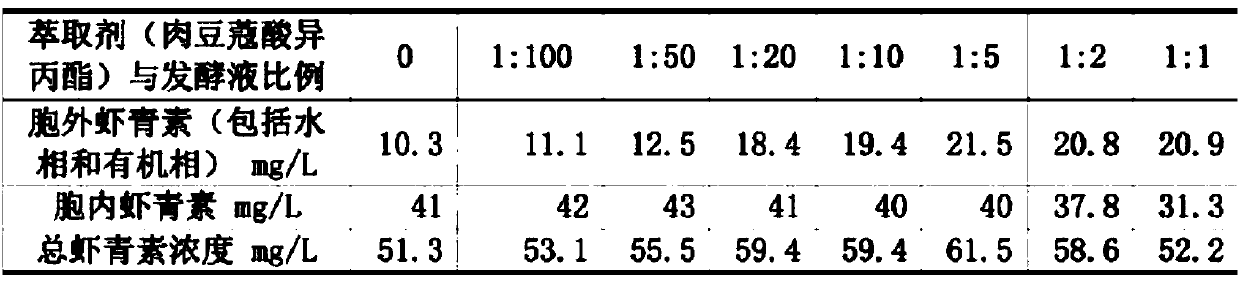

Embodiment 3

[0044] Step 1) prepare 5L culture medium, comprise 10g / L glucose, 2g / L (NH 4 ) 2 SO 4 , 4.2g / L KH 2 PO 4 and 11.24g / L K 2 HPO 4 , 1.7g / L citric acid, 0.5g / L MgSO 4 And 10mL / L trace element solution. Among them, the trace element solution contains 0.25g / L CoCl 2 ·6H 2 O, 1.5g / L MnSO 4 4H 2 O, 0.15g / L CuSO 4 2H 2 O, 0.3g / L H 3 BO 3 , 0.25g / LNa 2 MoO4· 2 h 2 O, 0.8g / L Zn(CH 3 COO) 2 , 5g / L iron (III) citrate and 0.84g / L EDTA, the pH of the trace element solution is 8.0.

[0045] Step 2) Sterilize the culture medium at 121° C. for 15-20 minutes. (Note, the glucose solution should be sterilized separately before mixing with other ingredients).

[0046] Step 3) Next, take 100mL of the culture medium and put them into the same #7 fermenter, #8 fermenter, #9 fermenter, #10 fermenter, #11 fermenter, #12 fermenter, #13 fermenter tank, #14 fermenter, all fermenters were 250 mL, and the fermentors were placed at a temperature of 121°C.

[0047] Step 4) Inoculate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com