Ceramic fluorescent sheet for LED and pressureless sintering method of ceramic fluorescent sheet

A technology of ceramic fluorescent sheet and sintering method, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of unstable and low relative density, and achieve the requirements of not strict experimental schedule, simple experimental process, and high thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Sr 1.97 Si 5 N 8 :0.03Eu 2+

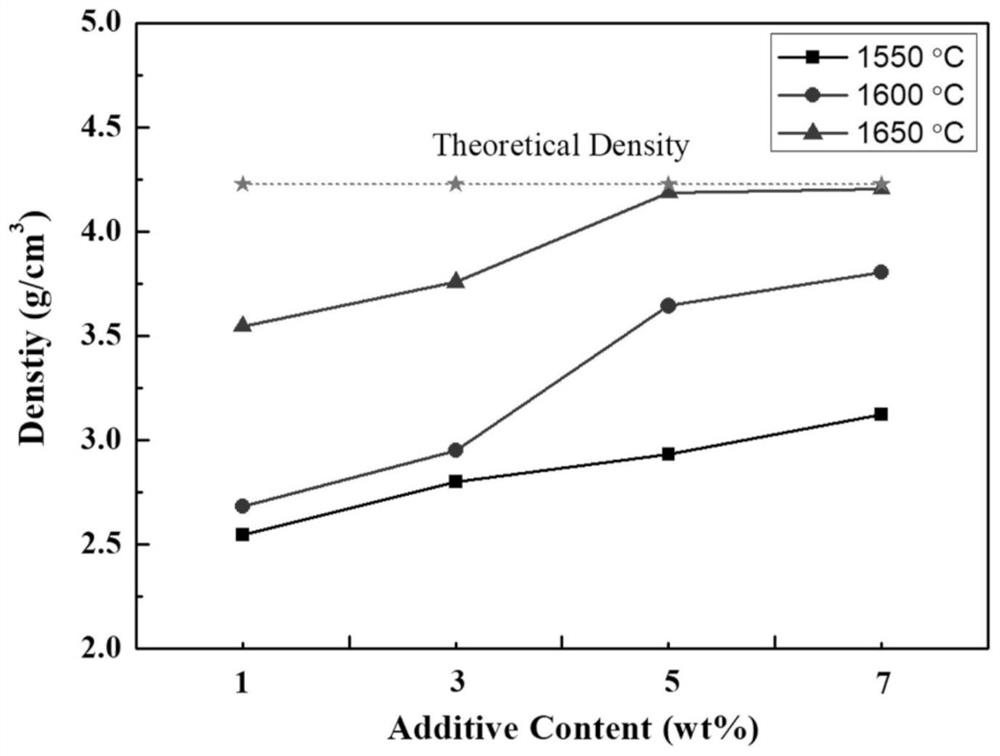

[0015] First, prepare the phosphor, and weigh Sr with a purity greater than 99.9% according to the stoichiometric ratio 3 N 2 、Eu 2 o 3 and Si 3 N 4 as raw material. The raw materials were ground and mixed with an agate mortar in an argon-filled glove box, ball milled on a planetary ball mill for 10 h, and then sealed with argon. Put the ball-milled powder in a tube furnace, pass through a hydrogen atmosphere in nitrogen with a hydrogen gas fraction of 10%, and calcinate at 1200° C. for 8 hours to obtain the phosphor. Then, sinter the ceramic phosphor, mix the synthesized phosphor with MgO and CaO with a purity greater than 99.9%, and the mass ratio of MgO to CaO is 0.5. The mass of MgO and CaO is 7% of the phosphor. The mixture was milled on a planetary ball mill using alumina balls for 5 hours, and then passed through a 200-mesh sieve. Use a uniaxial press to perform cold isostatic pressing at 300 MPa and hold the ...

Embodiment 2

[0016] Example 2: Ba 1.97 Si 5 N 8 :0.03Eu 2+

[0017] First, prepare the phosphor, and weigh Ba with a purity greater than 99.9% according to the stoichiometric ratio 3 N 2 、Eu 2 o 3 and Si 3 N 4 as raw material. The raw materials were ground and mixed with an agate mortar in an argon-filled glove box, ball milled on a planetary ball mill for 16 h, and then sealed with argon. Put the ball-milled powder in a tube furnace, pass through a hydrogen atmosphere in nitrogen with a hydrogen gas fraction of 5%, and calcinate at 1400° C. for 6 hours to obtain the phosphor. Then, sinter the ceramic phosphor, mix the synthesized phosphor with MgO and CaO with a purity greater than 99.9%, and the mass ratio of MgO and CaO is 2. The mass of MgO and CaO is 1% of the phosphor. The mixture was milled on a planetary ball mill using alumina balls for 7 hours, and then passed through a 200-mesh sieve. Use a uniaxial press, perform cold isostatic pressing at 150MPa, and hold the pres...

Embodiment 3

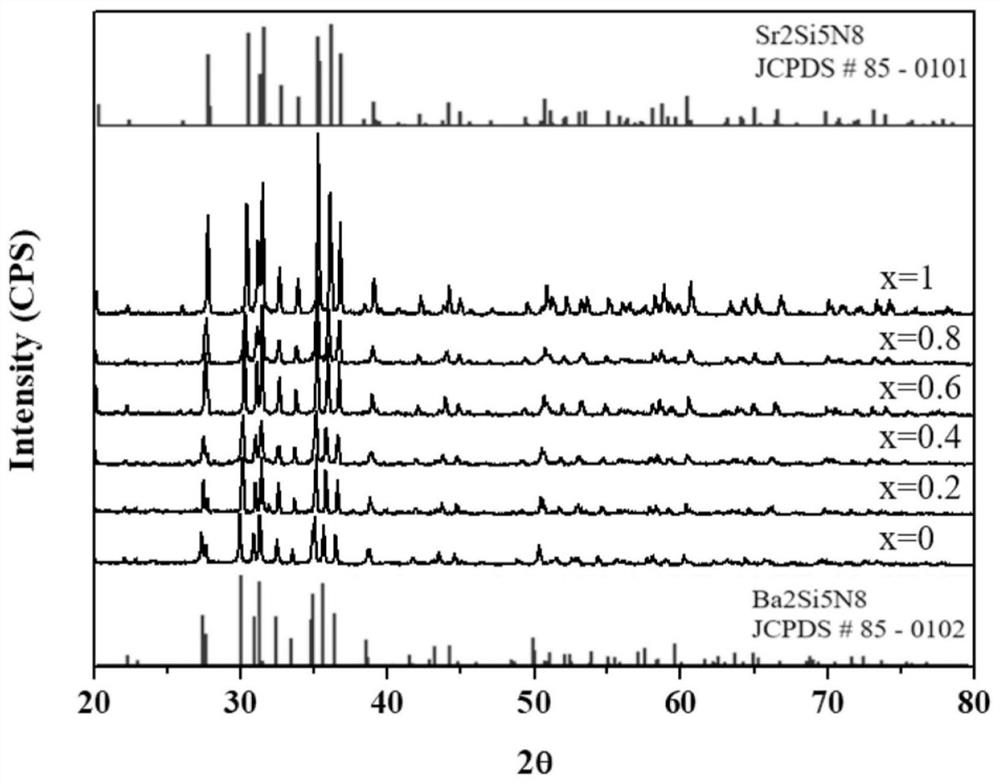

[0018] Embodiment 3: (Ba 0.8 ,Sr 0.2 ) 1.97 Si 5 N 8 :0.03Eu 2+

[0019] First, prepare the phosphor, and weigh Ba with a purity greater than 99.9% according to the stoichiometric ratio 3 N 2 、Sr 3 N 2 、Eu 2 o 3 and Si 3 N 4 as raw material. The raw materials were ground and mixed with an agate mortar in an argon-filled glove box, ball milled on a planetary ball mill for 10 h, and then sealed with argon. Put the ball-milled powder in a tube furnace, pass through a hydrogen atmosphere in nitrogen with a hydrogen gas fraction of 10%, and calcinate at 1200° C. for 8 hours to obtain the phosphor. Then, sinter the ceramic phosphor, mix the synthesized phosphor with MgO and CaO with a purity greater than 99.9%, and the mass ratio of MgO to CaO is 0.5. The mass of MgO and CaO is 7% of the phosphor. The mixture was milled on a planetary ball mill using alumina balls for 5 hours, and then passed through a 200-mesh sieve. Use a uniaxial press to perform cold isostatic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com