Puffing device for feed processing

An extruding device and feed processing technology, which is applied in feed, electromechanical devices, cooling/ventilation devices, etc., can solve the problems of insufficient temperature and affecting the effect of puffing, and achieve the effect of increasing the surface area, ensuring the effect of puffing, and ensuring the degree of puffing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

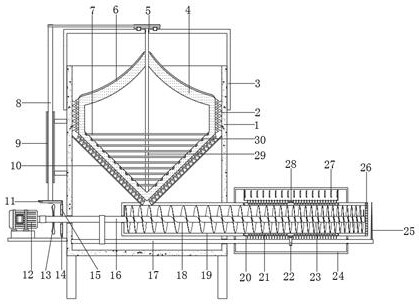

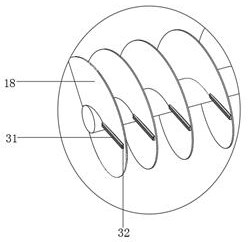

[0029] refer to Figure 1-4 , an extruding device for feed processing, comprising an extruding main box 1, an extruding cylinder 19 is fixedly installed on one side of the bottom end of the expanding main box 1, and the inner wall of the extruding cylinder 19 is connected with a screw extruding rod 16 through a bearing, and the screw extruding The outer wall of the rod 16 is provided with a helical piece, and the pitch between the helical pieces decreases in turn. The two ends of the screw extrusion rod 16 are respectively set as the feeding end 18 and the extrusion compression end 23, and one end of the puffing cylinder 19 is rotatably connected by a bearing. There is a heat exchange drum 20, and the end of the puffing drum 19 close to the heat exchange drum 20 is welded with an outer connecting cylinder 24, the top inner wall of the outer connecting cylinder 24 is fixedly installed with a heating wire 27, and the top of the puffing main box 1 is provided with a grinding and f...

Embodiment 2

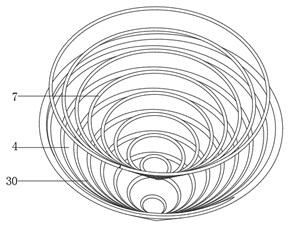

[0039] refer to figure 1 with Figure 5 , an extruding device for feed processing. Compared with Embodiment 1, this embodiment further includes that the outer peripheral wall of the heat exchange drum 20 is fixedly equipped with heat exchange rings 33 distributed equidistantly.

[0040] In the present invention, the outer circumferential wall of the heat exchange drum 20 is provided with pointed ring grooves 21 alternately distributed with the heat exchange ring fins 33 .

[0041] When the present invention is used: the heat exchange ring piece 33 and the sharp ring groove 21 arranged on the outer wall of the heat exchange drum 20 can effectively increase the surface area of the heat exchange drum 20 to improve the heat exchange effect and ensure the degree of expansion of the feed. the goal of.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com