A kind of exhaust gas mixer based on self-healing flame arrester

A fire retardant mesh and mixer technology, used in gas and gas/vapor mixing, fire rescue, chemical instruments and methods, etc., can solve the problems of film evaporation loss, stainless steel loss of antioxidant capacity, etc. High temperature oxidation protection ability, the effect of reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment one mainly sets forth the concrete structure of the present invention, and specific content is as follows:

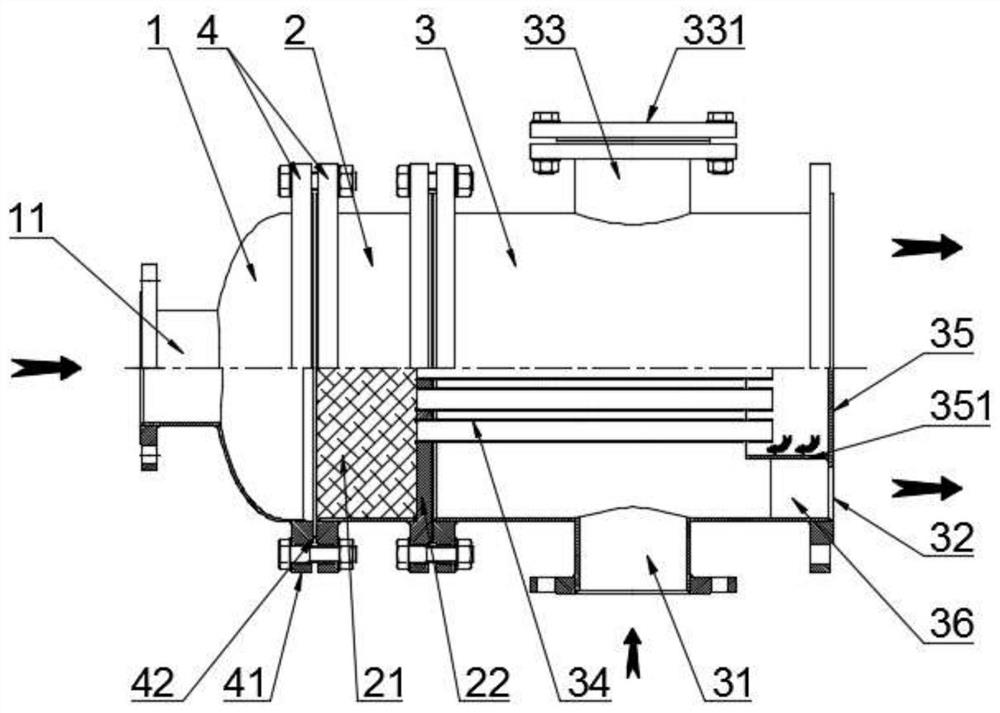

[0057] Such as figure 1 As shown, an exhaust gas mixer based on a self-healing fire arresting net, the exhaust gas inlet and outlet direction is the axis direction, and the exhaust gas mixer is composed of volume expansion chambers whose cross-sections are perpendicular to the same axis and arranged concentrically in sequence 1, fire arresting Chamber 2 and air mixing chamber 3; the joints of the capacity expansion chamber 1, fire retardant chamber 2 and air mixing chamber 3 are all connected by butt flanges 4.

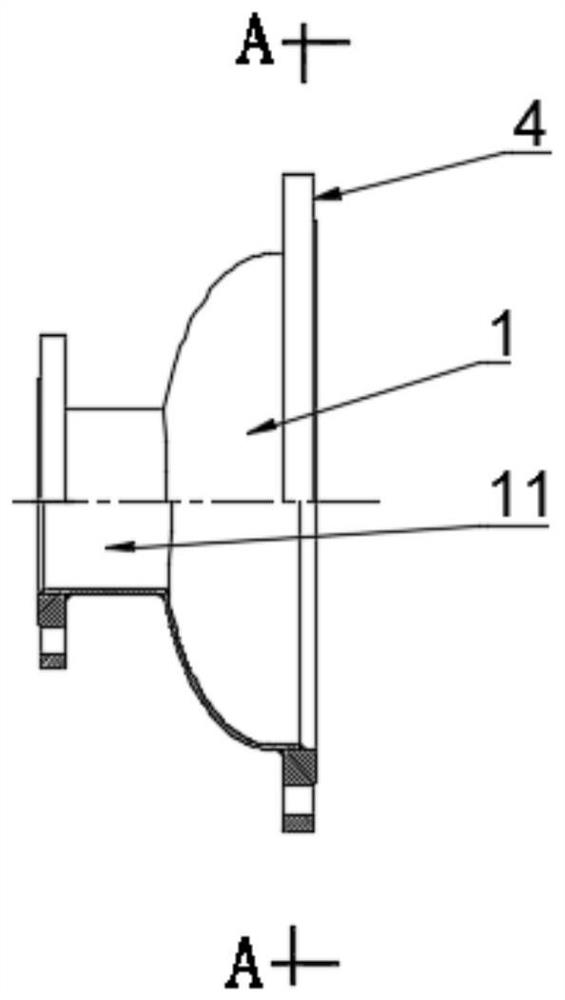

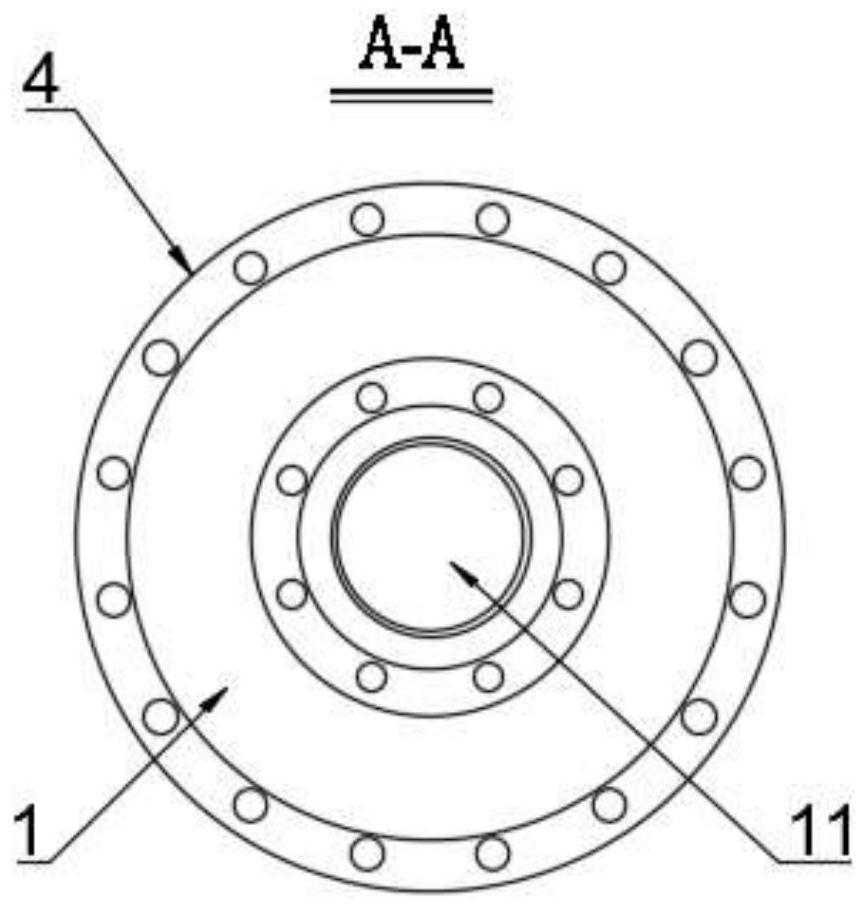

[0058] Such as figure 2 , image 3 As shown, the expansion chamber 1 starts from the waste gas inlet 11 provided at the intake end, and its inner diameter gradually expands along the axial direction until it is consistent with the inner diameter of the adjacent fire retardant chamber 2 .

[0059] Such as Figure 4 As shown, the inside of ...

Embodiment 2

[0071] The second embodiment is mainly to illustrate the preparation method of the self-healing fire-blocking net 21 used in the present invention.

[0072] In this embodiment, the base material of the self-healing fire-blocking net is 304N stainless steel, and its chemical composition is shown in Table 1.

[0073] Table 1 Composition of 304N stainless steel

[0074] C mn Si Cr Ni P S N ≤0.08 ≤2.00 ≤0.75 18.0~20.0 8.0~10.5 ≤0.045 ≤0.03 0.10~0.16

[0075] In this embodiment, the Al material used is industrial pure Al welding wire, and the reagents used are all commercial experimental pure reagents. Concrete preparation method is as follows:

[0076] S1. Preparation of spherical MoS 2

[0077] First, put ammonium molybdate and sodium thiosulfate with a molar ratio of 1:2 into two beakers respectively, and ultrasonically treat them with deionized water for 10 minutes; then mix the treated ammonium molybdate and sodium thiosulfate to adjust th...

experiment example

[0098] This experimental example is described on the basis of the preparation method of the self-healing fire-blocking net 21 in Example 2, and aims to clarify the anti-oxidation ability of the self-healing fire-blocking net 21 .

[0099] In this experimental example, group A is the blank control group - the preparation material of the fire resistance net is simple 304N stainless steel; group B is the experimental group - the preparation material of the fire resistance net is Al / Ni-MoS 2 / 45ct / stainless steel mesh. See Table 2 for the change of mass with heating time of groups A and B at 1100°C.

[0100] Table 2 The mass change of Group A and Group B during thermal oxidation

[0101]

[0102] It can be seen from the data in Table 2 that the uncoated group A stainless steel is severely oxidized in a short period of time, while the coated Al / Ni-MoS 2 / 45ct coated Group B stainless steel is substantially free from oxidation. Because it forms a dense aluminum oxide protecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com