Crushing and grinding device for agricultural crop production

A technology of crushing, grinding and cropping, which is applied in the field of crushing and grinding of peanuts, and can solve problems such as trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

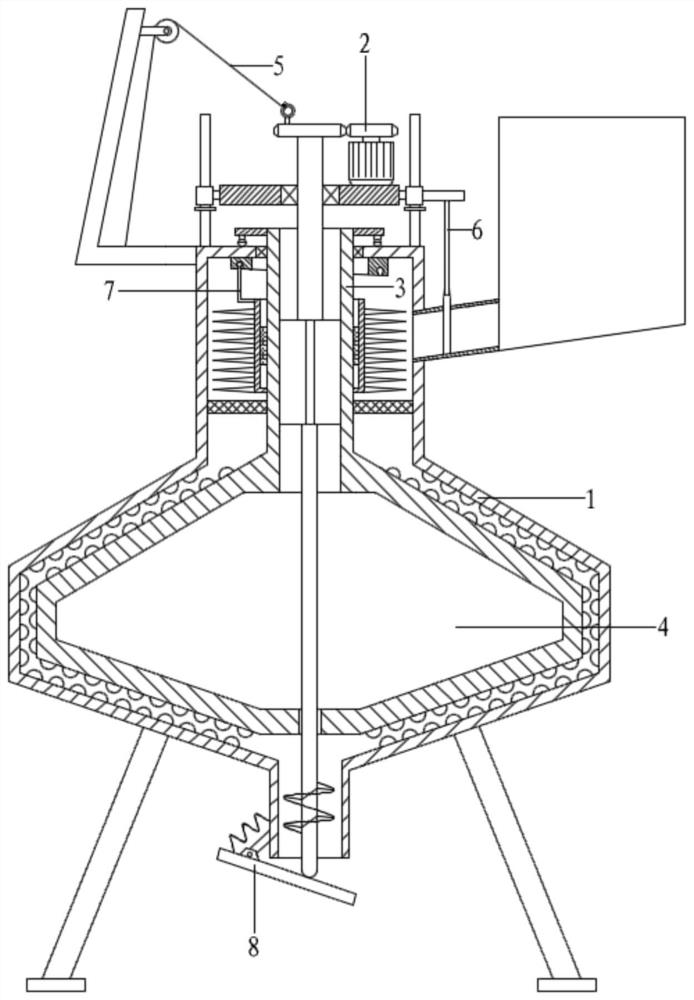

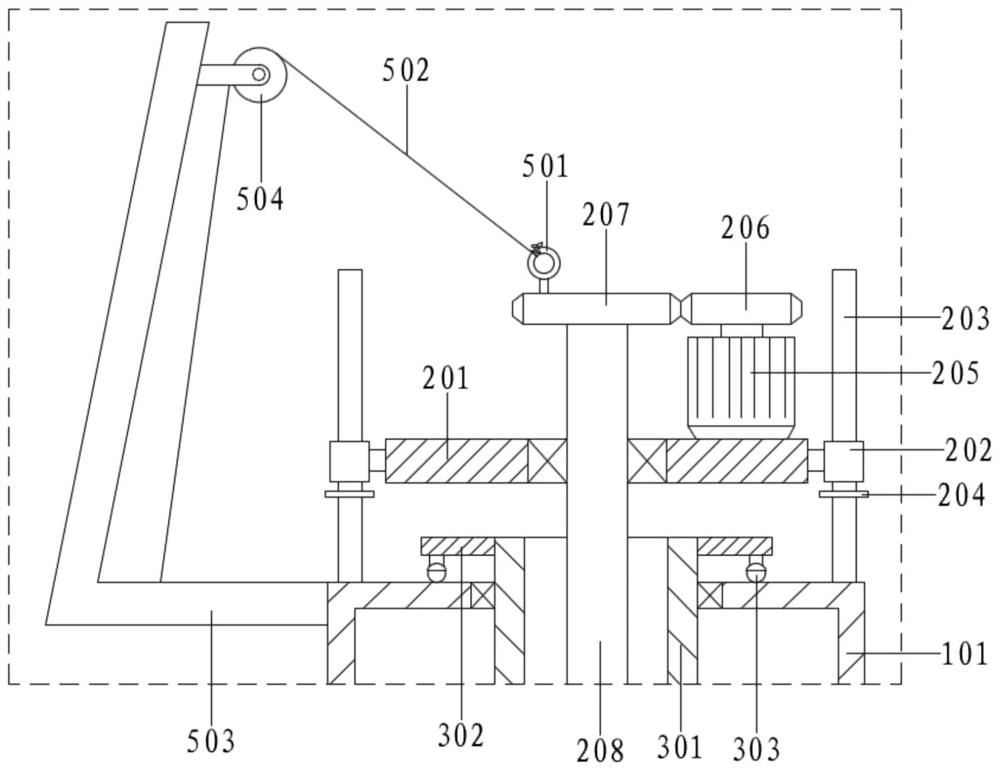

[0056] With reference to the accompanying drawings, a crushing and grinding device for agricultural crop production includes a tank assembly 1, a drive assembly 2, a crushing assembly 3, a grinding assembly 4, a pulling assembly 5 and a discharge assembly 8;

[0057] The tank assembly 1 includes a crushing cylinder 101, a grinding chamber 102, a discharge pipe 103, a leg 104, a feeding pipe 105, a feeding box 106 and a sieve plate 107; the crushing cylinder 101 is vertically arranged, and the bottom end is connected with a grinding chamber 102; The bottom of the grinding chamber 102 is connected with a support leg 104, and the bottom end is connected with a discharge pipe 103; the right side of the crushing cylinder 101 is provided with a feeding box 106, and the bottom of the feeding box 106 is connected with a feed pipe 105 inclined to the left, and the feed pipe 105 and The middle part of the crushing cylinder 101 is connected; the crushing cylinder 101 is also equipped with...

Embodiment 2

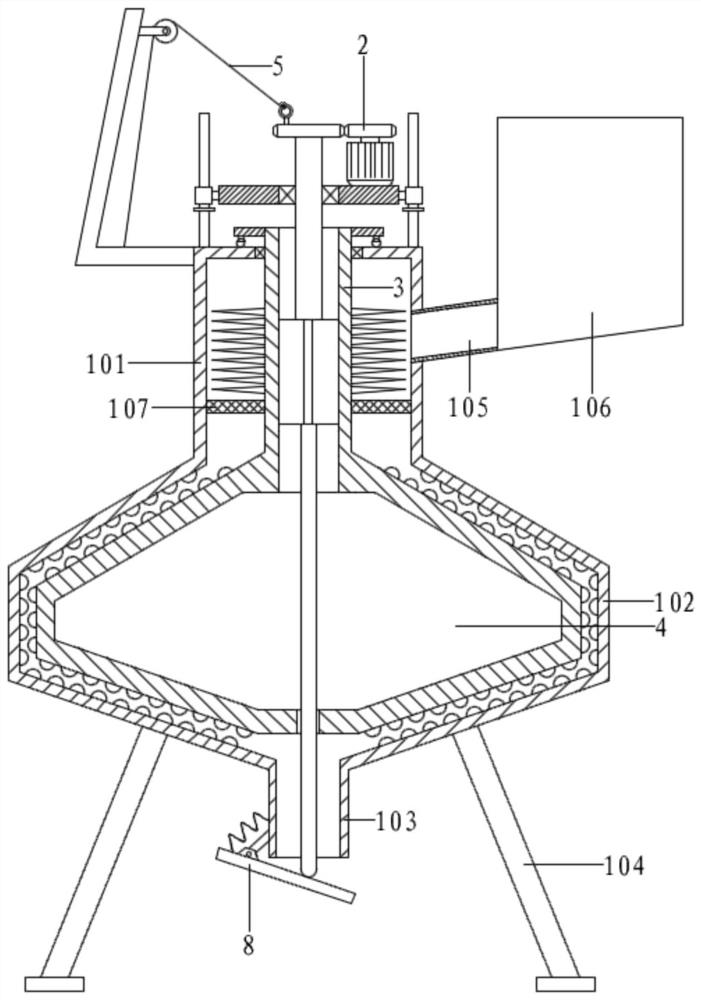

[0060] With reference to the accompanying drawings, a crushing and grinding device for agricultural crop production includes a tank assembly 1, a drive assembly 2, a crushing assembly 3, a grinding assembly 4, a pulling assembly 5 and a discharge assembly 8;

[0061] The tank assembly 1 includes a crushing cylinder 101, a grinding chamber 102, a discharge pipe 103, a leg 104, a feeding pipe 105, a feeding box 106 and a sieve plate 107; the crushing cylinder 101 is vertically arranged, and the bottom end is connected with a grinding chamber 102; The bottom of the grinding chamber 102 is connected with a support leg 104, and the bottom end is connected with a discharge pipe 103; the right side of the crushing cylinder 101 is provided with a feeding box 106, and the bottom of the feeding box 106 is connected with a feed pipe 105 inclined to the left, and the feed pipe 105 and The middle part of the crushing cylinder 101 is connected; the crushing cylinder 101 is also equipped with...

Embodiment 3

[0082] The difference from Embodiment 2 is that the horizontal position of the crushing knife 305 in this embodiment changes when it is working.

[0083]It also includes a lifting assembly 7; the lifting assembly 7 is arranged in the crushing cylinder 101, including an annular boss 701, a chute 702, a chuck 703, a third connecting rod 704 and an outer cylinder 705;

[0084] The outer cylinder 705 is located above the sieve plate 107, and is set on the hollow shaft 301; the inner wall of the outer cylinder 705 is processed with a card groove, and the outer wall of the hollow shaft 301 is correspondingly processed with a convex key 306, and the convex key 306 is matched with the card groove; the inner top of the crushing cylinder 101 An annular boss 701 is fixedly connected, and the hollow shaft 301 passes through the annular boss 701; the bottom surface of the annular boss 701 is processed with a slope and an annular chute 702; It is circular, and the chuck head 703 is a corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com