Comprehensive dust raising type circulating separation system and separation method

A separation system and separation chamber technology, applied in the field of particle size separation, can solve the problems of unrecyclable coarse lime, easy clogging, and inability to repeat separation, etc., to achieve the effect of improving separation effect, facilitating practical operation, and improving adequacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

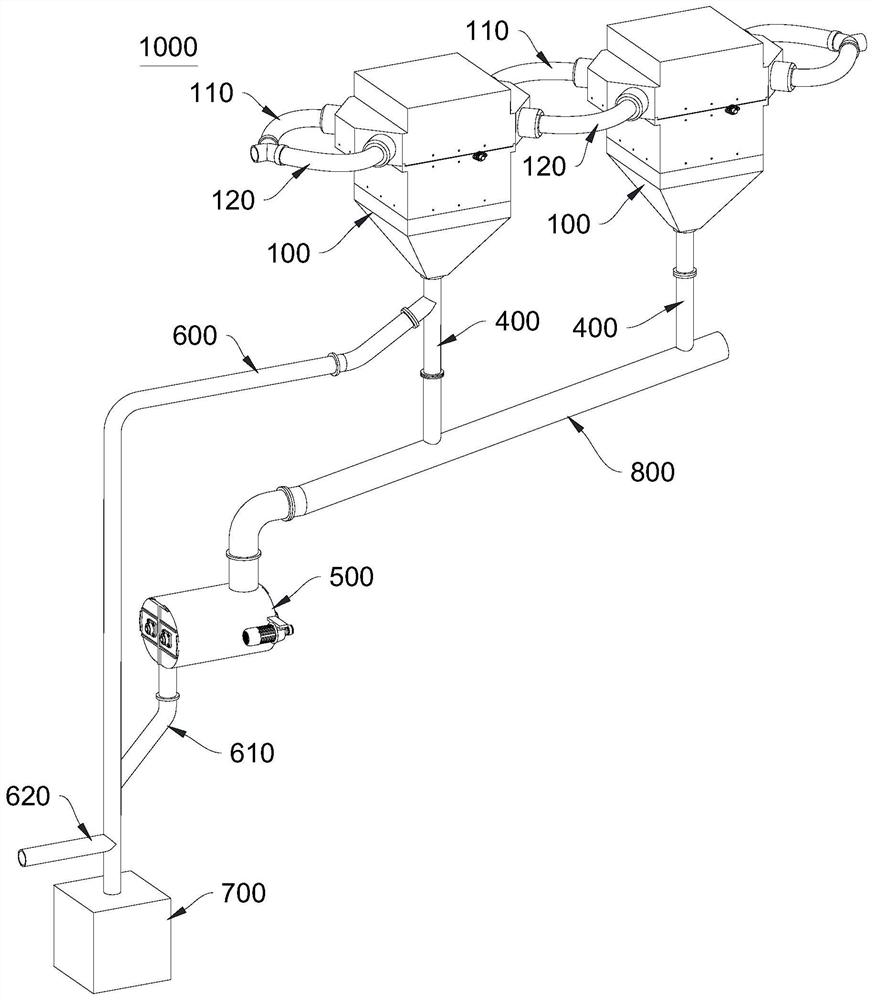

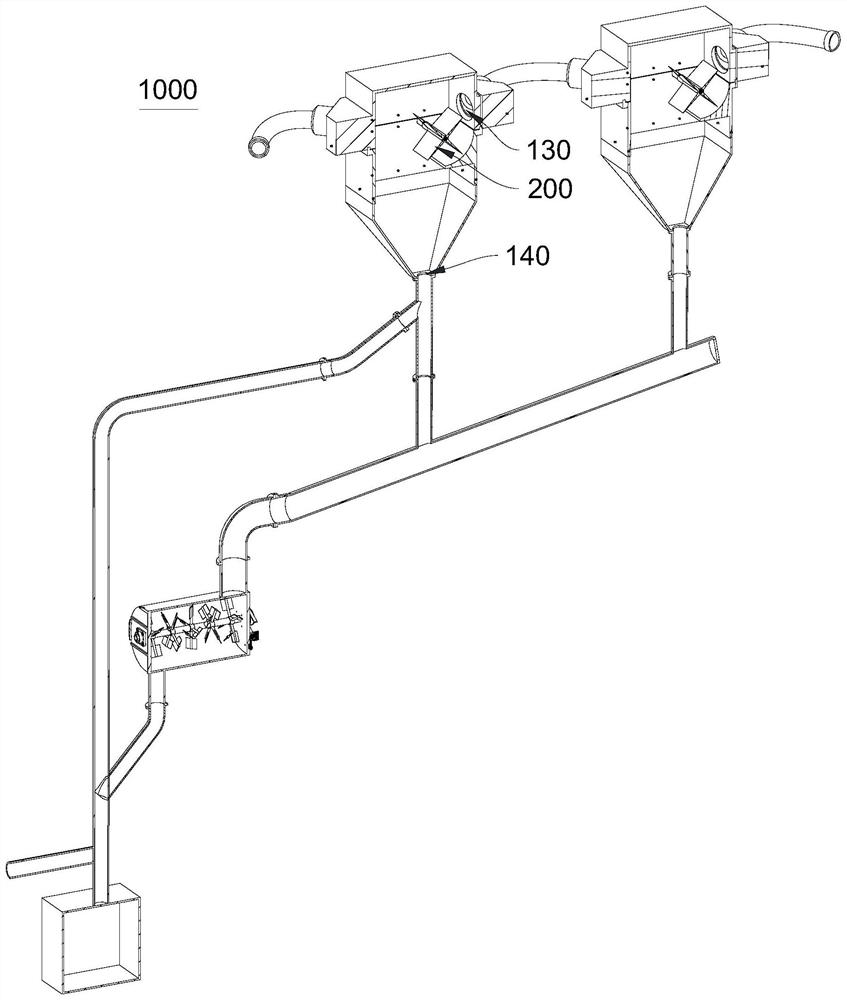

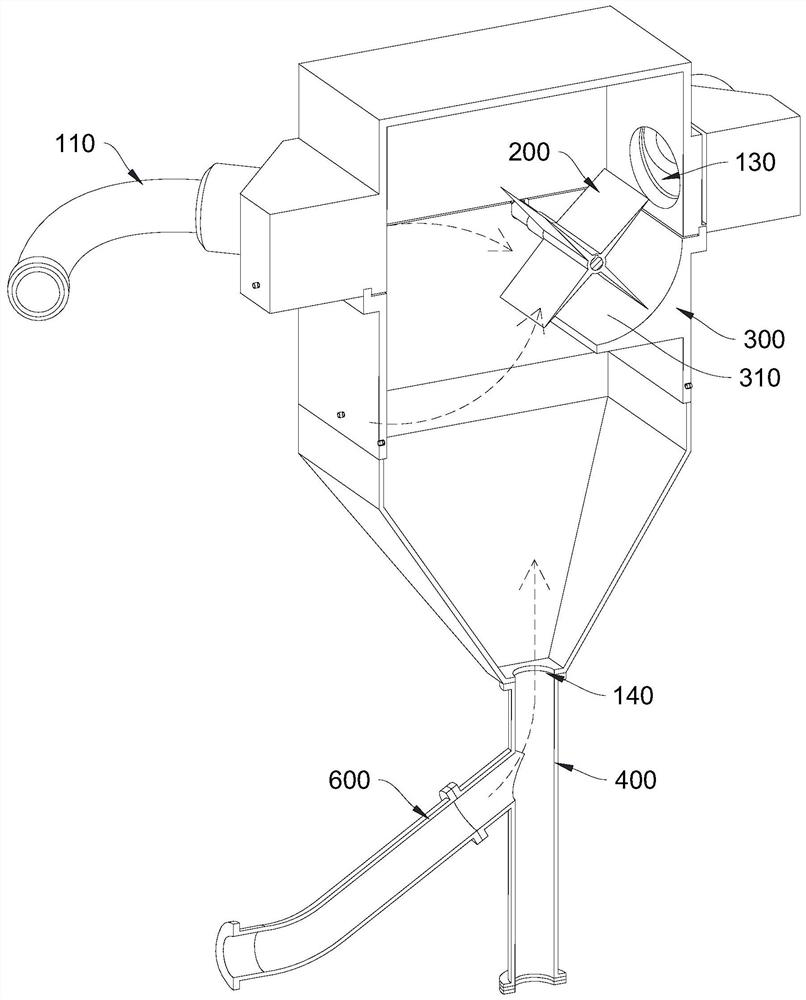

[0039] Please refer to Figure 1~3 , this embodiment provides a comprehensive dust-raising type circulation separation system 1000 .

[0040] The integrated dust-flying circulation separation system 1000 includes: a separation chamber 100 , a first feed pipeline 110 and a second feed pipeline 120 .

[0041] Both the first feed pipe 110 and the second feed pipe 120 communicate with the upper part of the separation chamber 100 and the outlet ends of the two are opposite to each other. The discharge channel 130 of the separation chamber 100 is also located in its upper part. The bottom of the separation chamber 100 is provided with a discharge port 140 for the coarse material to fall out.

[0042] During use, the material to be separated is blown into the separation chamber 100 by the airflow through the first feed pipe 110 and the second feed pipe 120, and the material particles with smaller particle size are lighter. Leaves the separation chamber 100 through the discharge ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com