Ultrasonic magnetic field impact rolling optimization device for linear weld joint of plate

A linear welding seam and impact rolling technology, applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of heavy rolling equipment, large space occupation, general rolling effect, etc., to increase shaping, improve Quality, reduce the effect of welding residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

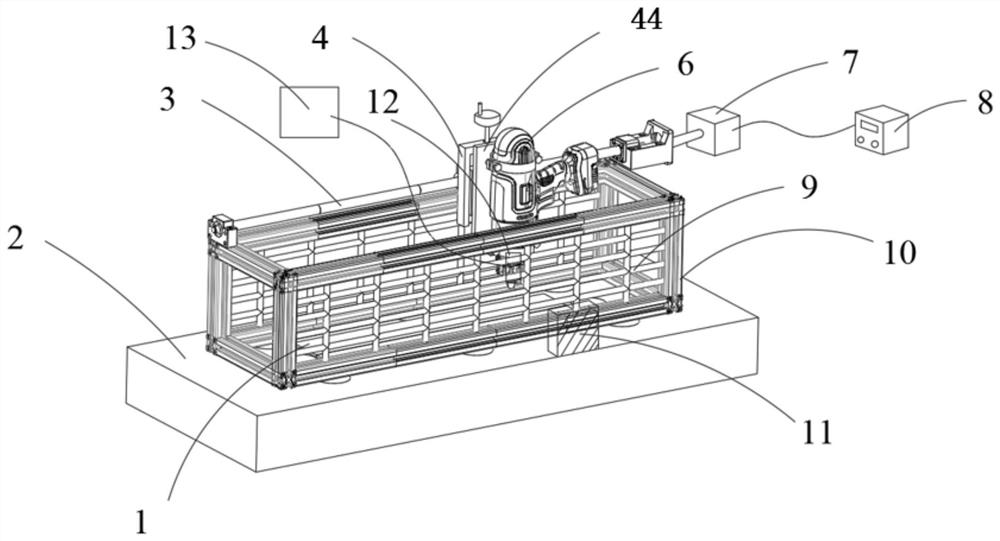

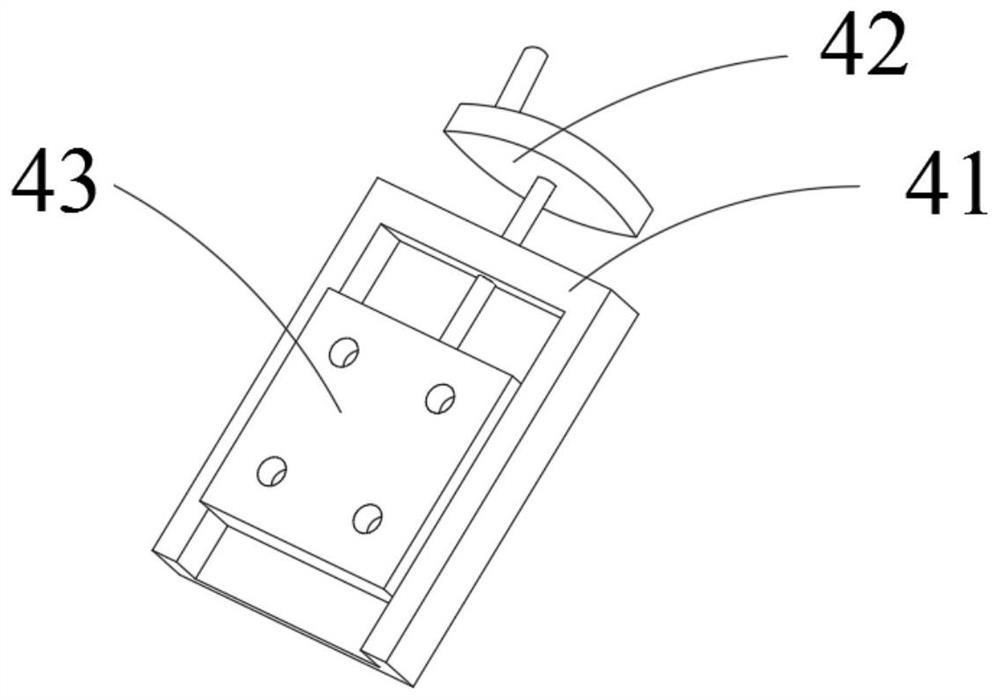

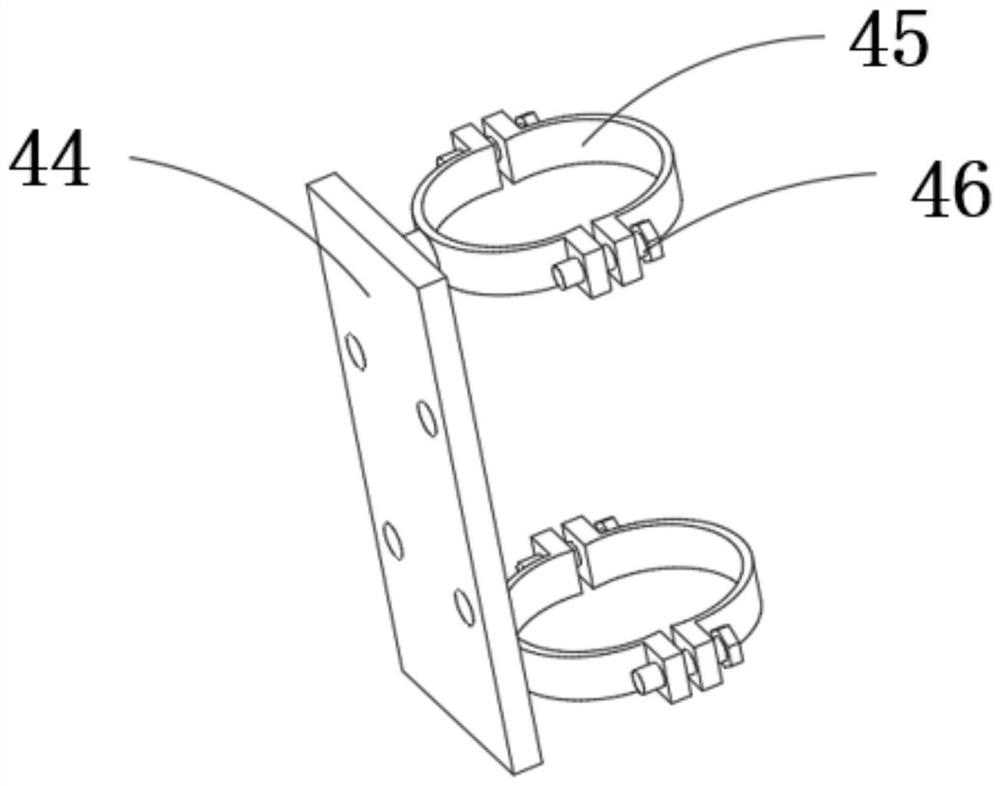

[0024] Embodiment 1: A device of this embodiment for optimizing the ultrasonic magnetic field impact rolling of straight welded seams of plates, its structure is as follows figure 1 As shown: a rectangular parallelepiped aluminum alloy frame 10 is installed on the welding platform 2, the frame is surrounded by a protective net 9, the welding plate 1 is placed on the upper surface of the welding platform 2, and is located between the frame 10 and the welding platform 2 Between, the first feeding mechanism is installed on the frame 10, including the first lead screw 3, the first slider, the first sliding frame, the motor 7, and the controller 8.

[0025] The first leading screw 3 is parallel to the surface of the welding platform 2 and parallel to the weld seam on the plate. The first sliding frame is equal to the first leading screw 3 and is fixedly connected to the first leading screw 3. The two ends of the first sliding frame are connected to the first leading screw 3. The fi...

Embodiment 2

[0033] Embodiment 2: According to another embodiment of the present invention, in a device for optimization of ultrasonic magnetic field impact rolling of linear weld seams of plates, the impact hammer is a pneumatic impact hammer.

[0034] For other structures and usage methods, please refer to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com