Automatic machining process for electrical cabinet

A technology for automatic processing and electrical cabinets, applied in the field of electrical cabinets, can solve the problems of reducing work efficiency, delaying production plans, and long processing time, saving space, reducing labor costs, and facilitating disassembly and cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

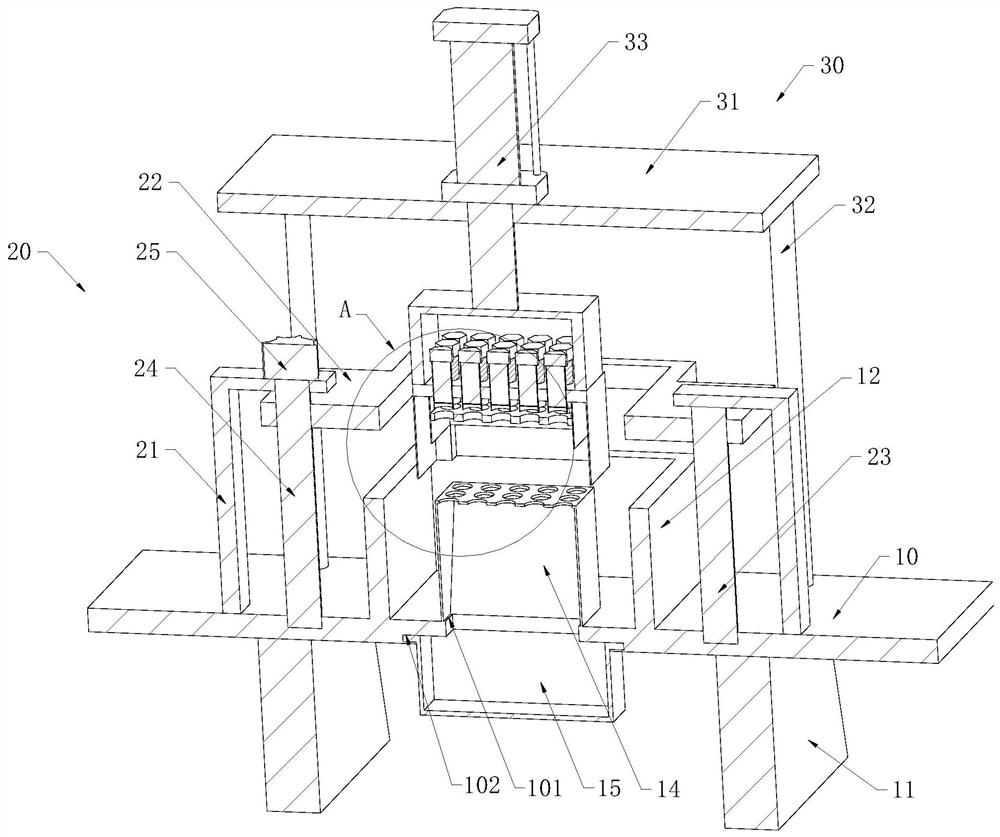

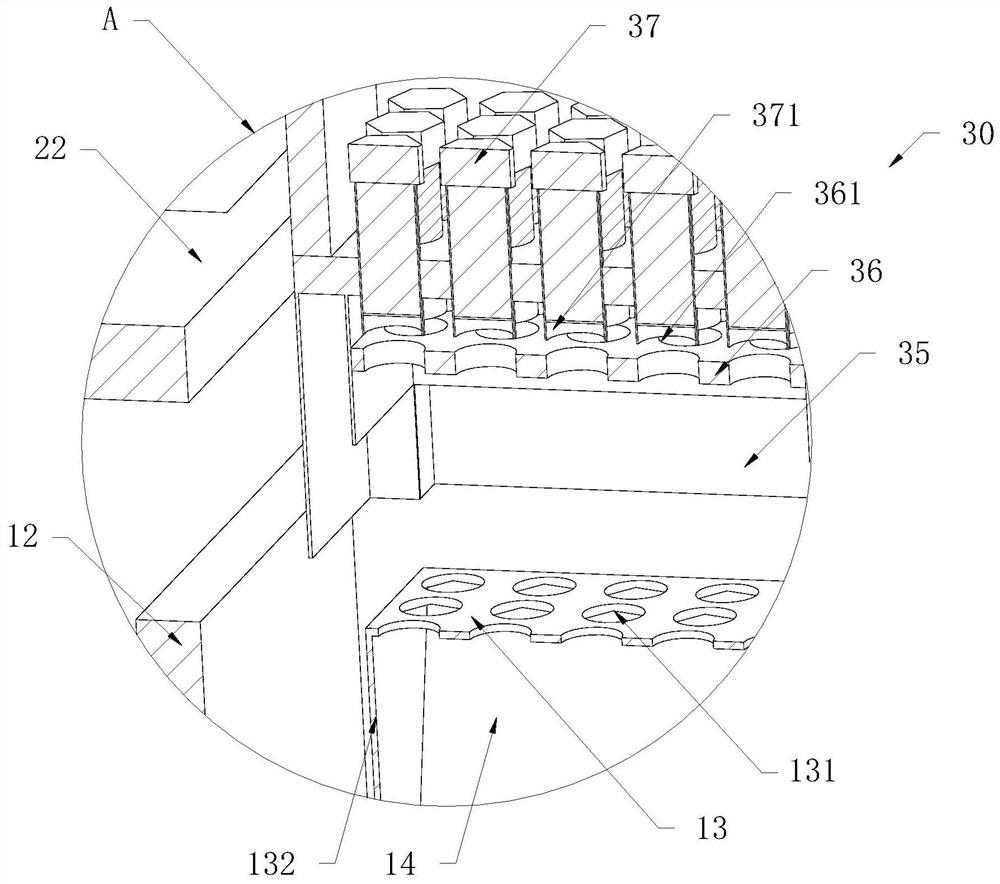

[0033] Such as Figure 1 to Figure 7 Shown, a kind of electrical cabinet automatic processing technology, it has used a kind of shearing machine, this shearing machine workbench 10 and the trapezoidal plate 11 that is arranged on the left and right ends of the bottom of workbench 10, the top center of workbench 10 is provided with a No. Back-shaped frame 12, the inner center of the No. 1 back-shaped frame 12 and the top of the workbench 10 are provided with a support platform 13, and the bottom of the support platform 13 is provided with a square groove 132, and the square groove 132 is along the bottom of the support platform 13. Extending in the height direction, the top of the supporting platform 13 is provided with multiple groups of round holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com