Staggered edge drill reamer for composite hole machining

A composite material and hole processing technology, which is applied in the direction of reamers, manufacturing tools, drilling accessories, etc., can solve the problems of poor mirror processing effect, etc., and achieve the effect of improving chip removal, easy installation and disassembly, dense and hard metal surface structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

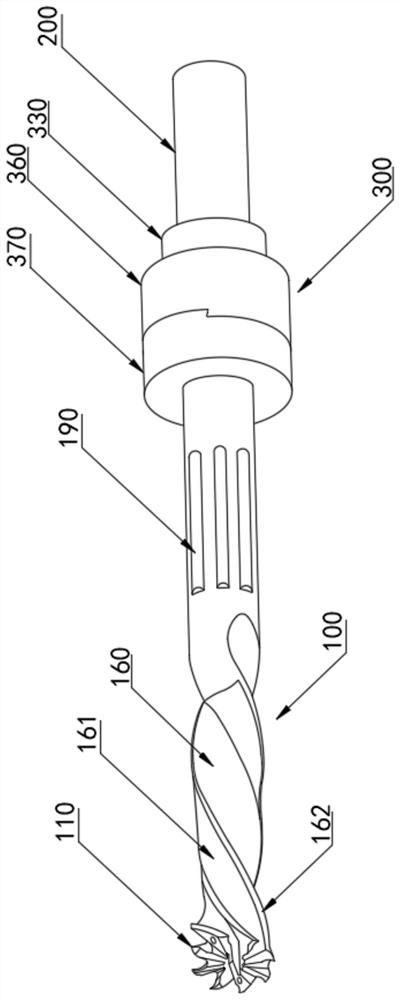

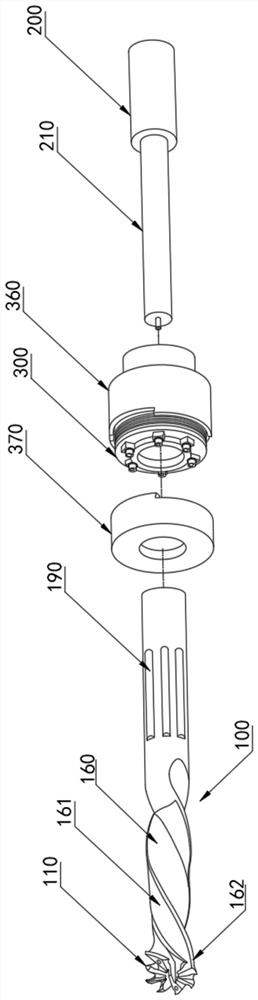

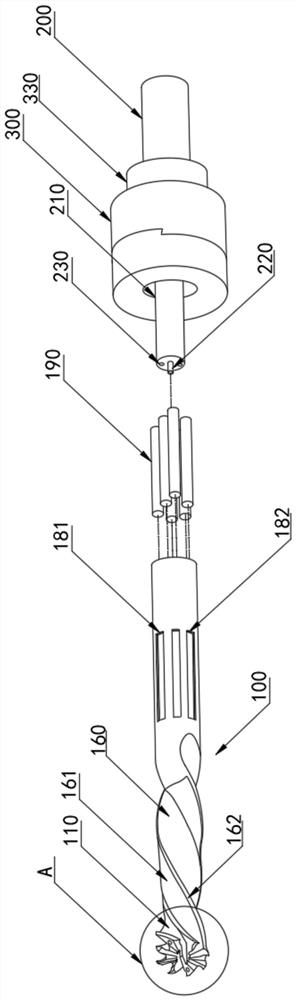

[0039] Embodiment 1, with reference to attached Figure 1-14 , a composite material hole processing staggered edge drill reamer provided by the present invention includes a drill rod 100, a tail handle 200 and an adjustment device 300, the right end of the drill rod 100 is provided with an adjustment device 300, and the adjustment device 300 includes a shell one 310, specifically , a parallel bearing 312 is fixedly installed on the left side of the first shell 310, a second shell 320 is fixedly installed on the left side of the parallel bearing 312, a limit ring 330 is fixedly installed on the right side of the first shell 310, and a tail handle 200 is fixedly installed on the right side of the limit ring 330, The mandrel 210 is fixedly installed on the left side of the tail handle 200, and the mandrel 210 is installed on the inner wall of the shell 1 310 and the shell 2 320, and the left side of the shell 2 320 is provided with a through hole 1 324, and the adjustment device 3...

Embodiment 2

[0052] Refer to the attached Figure 15 , a composite material hole processing staggered edge drill reamer in this embodiment also includes a limit frame 184;

[0053] Further, the limit frame 184 is fixedly installed on the inner wall of the installation groove 181, and the roller 190 is movably installed on the inner wall of the limit frame 184. Specifically, the limit frame 184 is set in a cage shape, and the roller 190 can be installed on the limit frame 184 inner wall first. , the limit frame 184 is installed on the inner wall of the installation groove 181, and the limit frame 184 has the function of facilitating the installation of the roller 190. The limit frame 184 is made of Teflon, and Teflon uses fluorine to replace all polyethylene. The artificially synthesized polymer material of hydrogen atoms, polytetrafluoroethylene has the characteristics of high temperature resistance, extremely low friction coefficient, good wear resistance and excellent chemical stability,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com