Electrically controlled mechanical cutting machine

An electrical control, mechanical technology, applied in metal processing machinery parts, planers, shearing devices, etc., can solve the problems of troublesome operation, generate a lot of dust, difficult to move, save time, improve work efficiency, practical strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

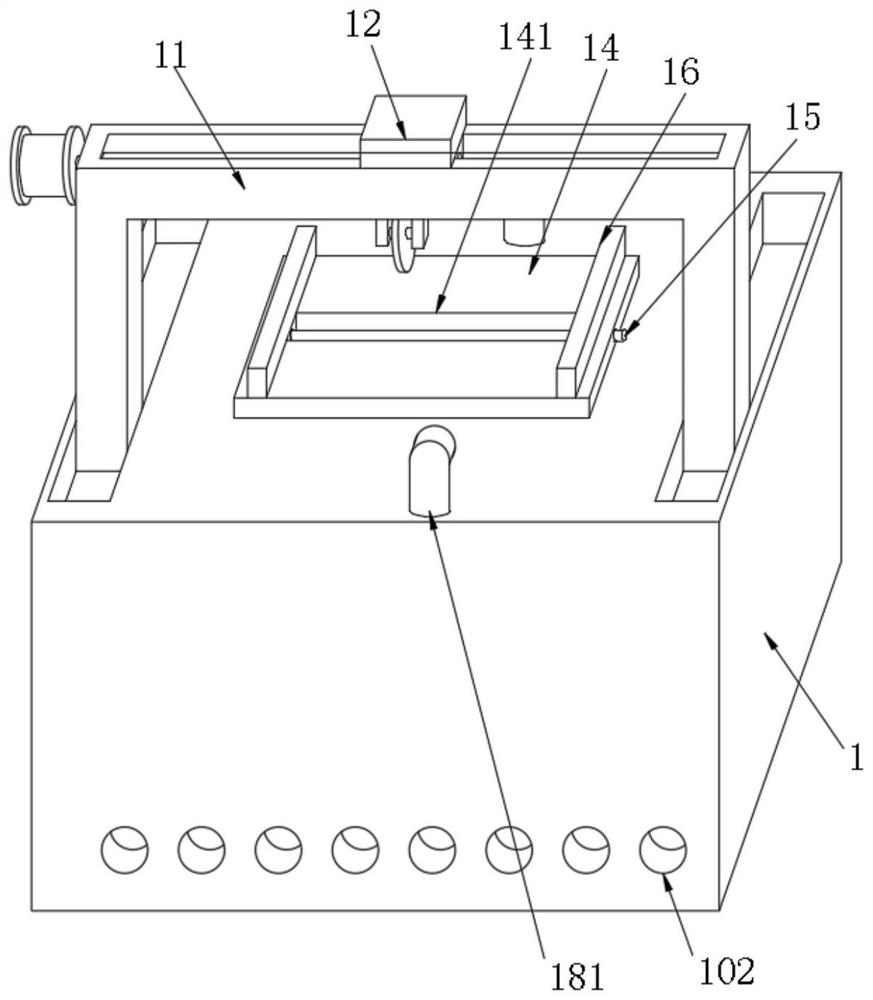

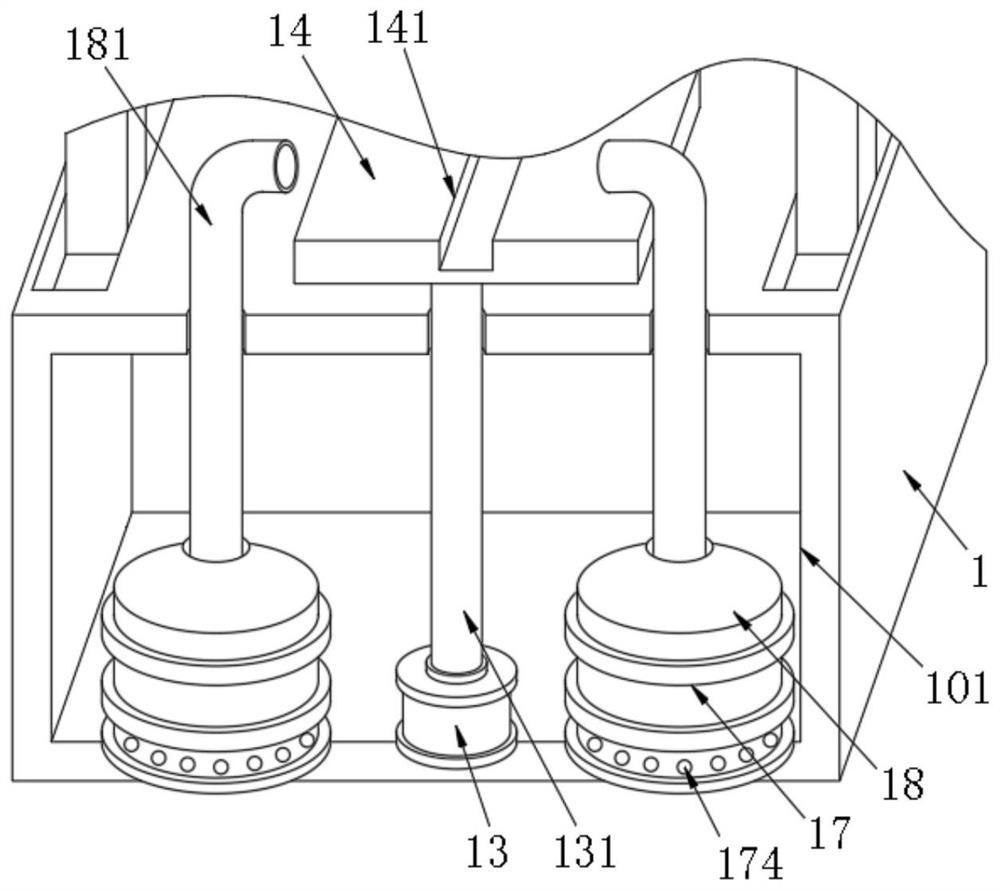

[0032] see Figure 1~4 , this specific embodiment describes in detail an electrically controlled mechanical cutting machine. The cutting machine includes a cabinet body 1, the inside of the cabinet body 1 is provided with a cavity 101, the top of the cabinet body 1 is slidably connected with a mobile frame 11 capable of positioning and moving, and the mobile frame 11 is positioned and connected with a mobile frame capable of positioning and moving along the mobile frame. Cutting mechanism 12 for mechanical cutting. The structure of the mobile frame capable of positioning and moving, the cutting mechanism capable of positioning and moving along the moving frame, and the structure of the cutting mechanism itself are all conventional technical solutions in the field, and will not be repeated in this application.

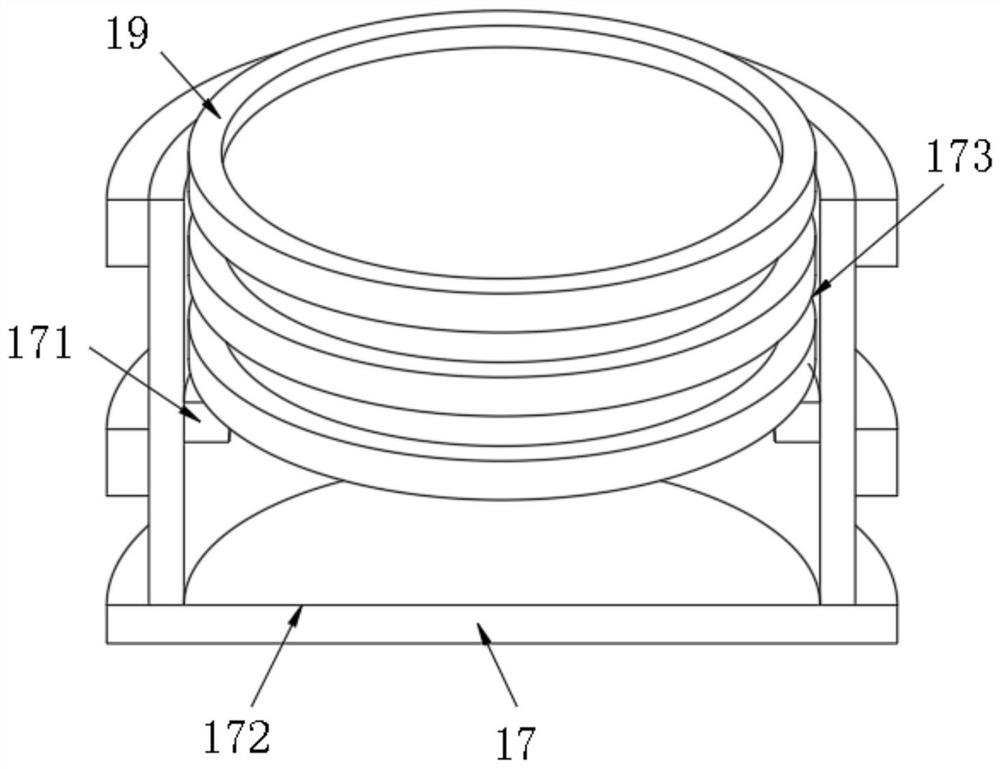

[0033] A motor 13 (model YL-7112) is fixedly connected inside the cavity 101, and a rotating shaft 131 is fixedly connected to the output end of the motor 13. The rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com